Pneumatic power device

A power device and pneumatic technology, which is applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve the problems of many valve precision patents, difficult and low-cost civilian use, and high market price, so as to reduce the volume and weight of the system, The effect of low carbon emissions and low quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment of description, but protection scope of the present invention is not limited thereto:

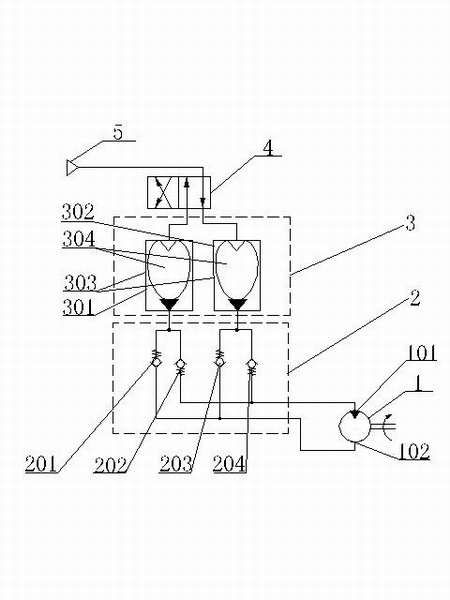

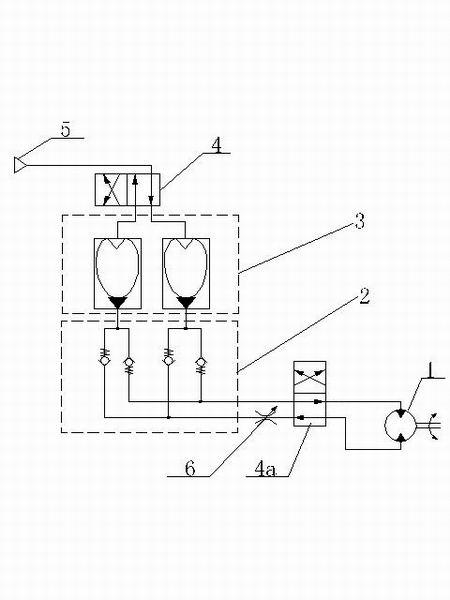

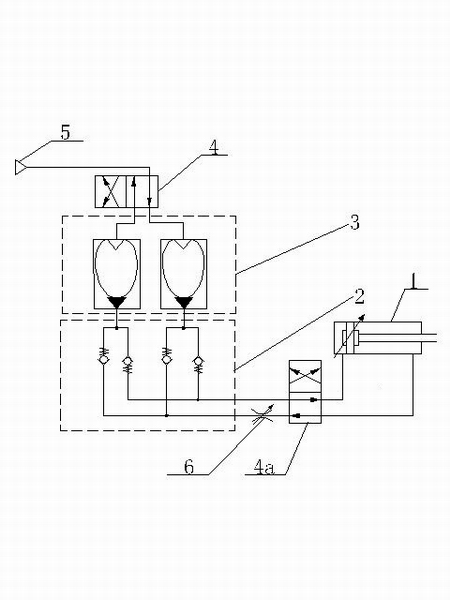

[0028] like Figure 1-4 As shown, a pneumatic power device includes an actuator 1, a bridge rectifier valve 2, a gas-liquid conversion multiplexer 3, a two-position four-way reversing valve 4, and an air source 5 that are sequentially connected back and forth. The rectifier valve 2 includes a first one-way valve 201, a second one-way valve 202, a third one-way valve 203 and a fourth one-way valve 204 that constitute a rectification backflow, and the gas-liquid conversion multiplexer 3 includes the first gas-liquid A liquid converter 301 and a second gas-liquid converter 302. One end of the first gas-liquid converter 301 is connected to the two-position four-way reversing valve 4, and the other end is connected to the first one-way valve 201 and the second one-way valve respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com