Direct illumination type light guide plate of light-emitting diode (LED) backlight

A technology of LED backlight and light guide plate, which is applied in the direction of light guide, light source, point light source, etc. It can solve the problems of difficult backlight heat dissipation, inability to control light localization, and difficulty in thinning, etc., to achieve good heat dissipation, excellent uniform brightness non-bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Although the embodiments of the present invention will be described below, the following descriptions are only to illustrate the principles of the present invention, rather than limiting the present invention to the descriptions of the following embodiments.

[0026] Note: the following items are applicable to all embodiments of the direct-type light guide plate of the LED backlight of the present invention:

[0027] (1) The ratio of each part in each figure does not represent the actual ratio of each part in the embodiment.

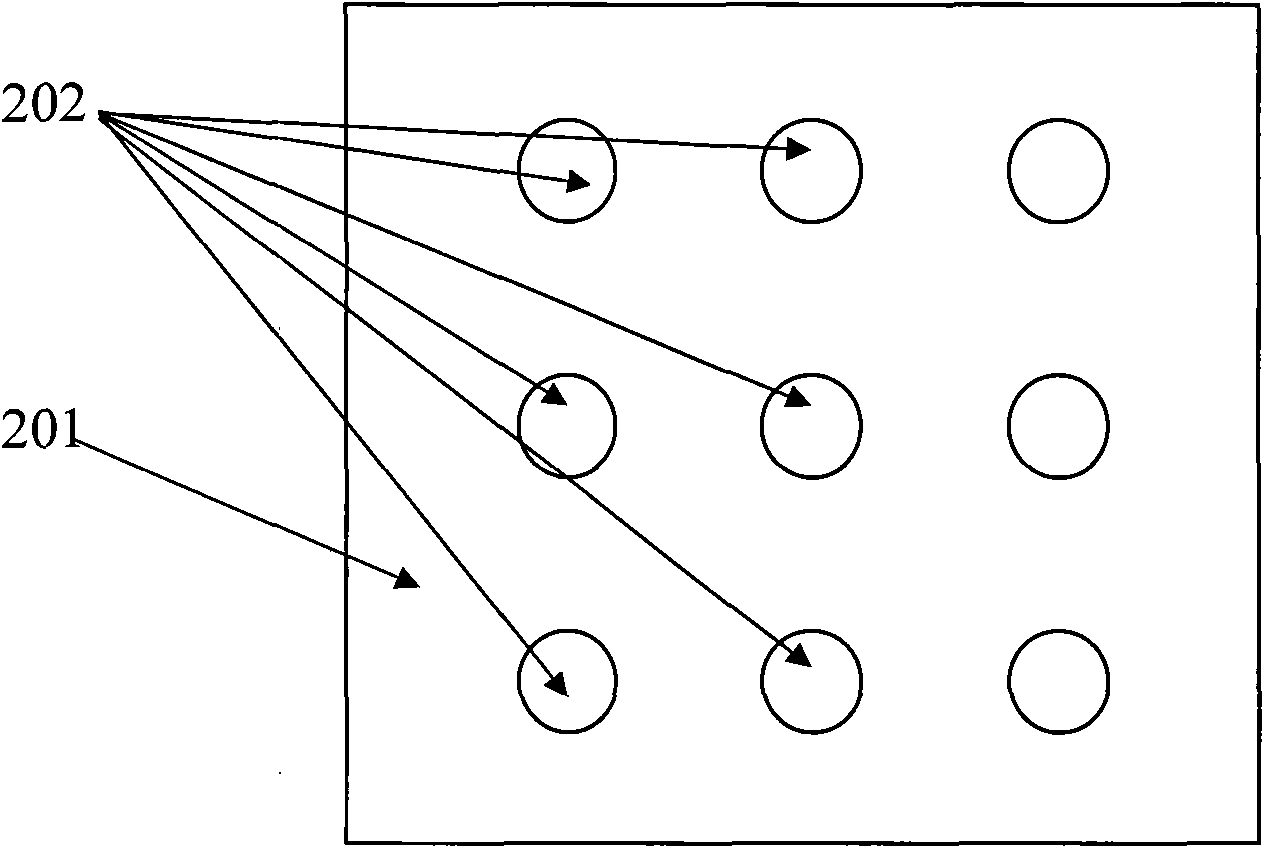

[0028] (2) The LED backlight of the liquid crystal display is constituted by a light-emitting element composed of a single or multiple direct-type light guide plates.

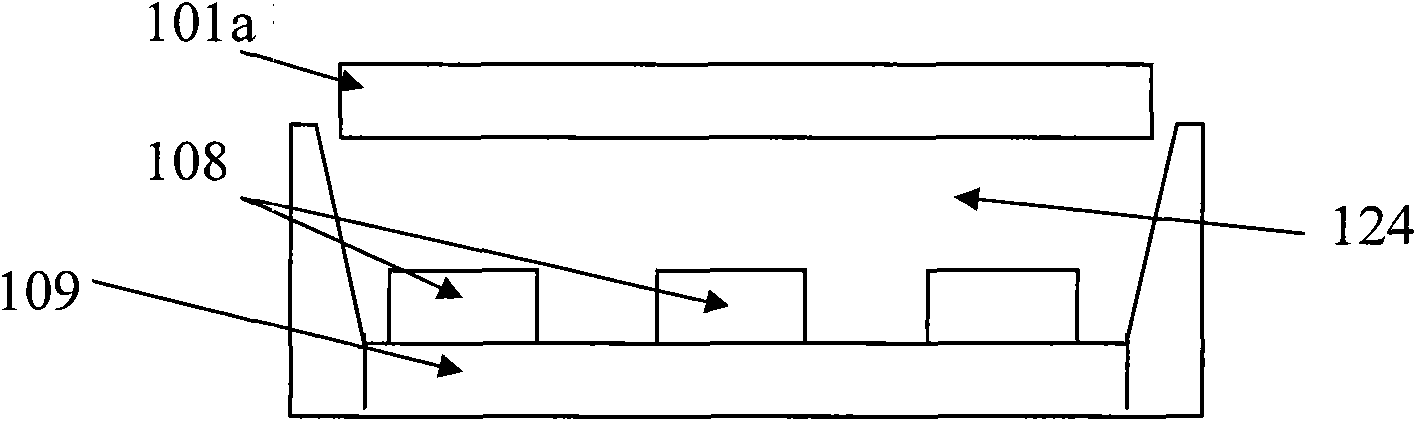

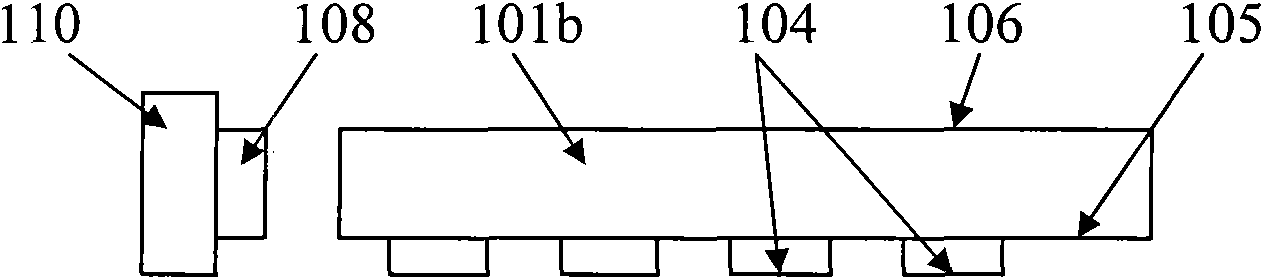

[0029] (3) Other components of the light-emitting element of the LED backlight are not shown in FIG. 5 , and other components include light collecting sheets, polarizers, reflectors, frames, and the like.

[0030] (4) A concave portion is formed on the top of the direct type light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com