Optical fiber insert core and preparation method thereof as well as quick joint

A fiber optic ferrule and ferrule technology, which is applied in the field of quick connectors, preparation, and fiber optic ferrules, can solve the problems of impossibly precise aperture, complex structure, and high price of glass capillary tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

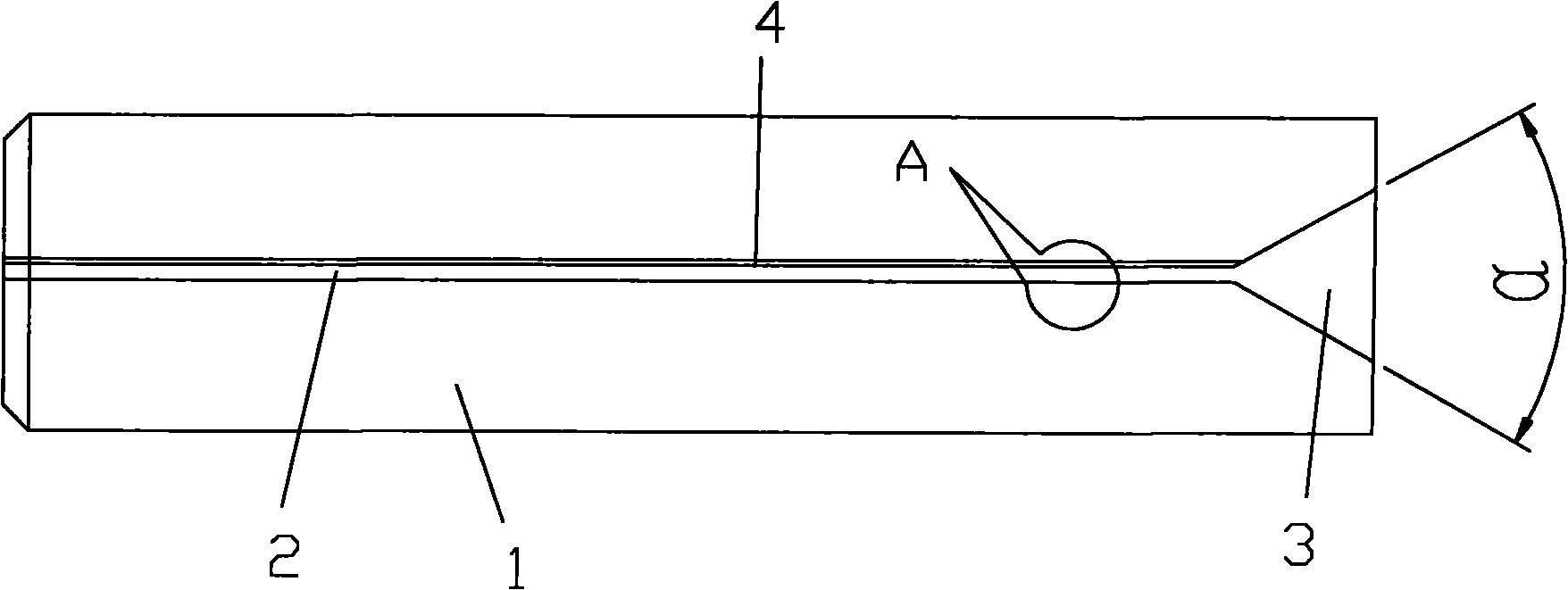

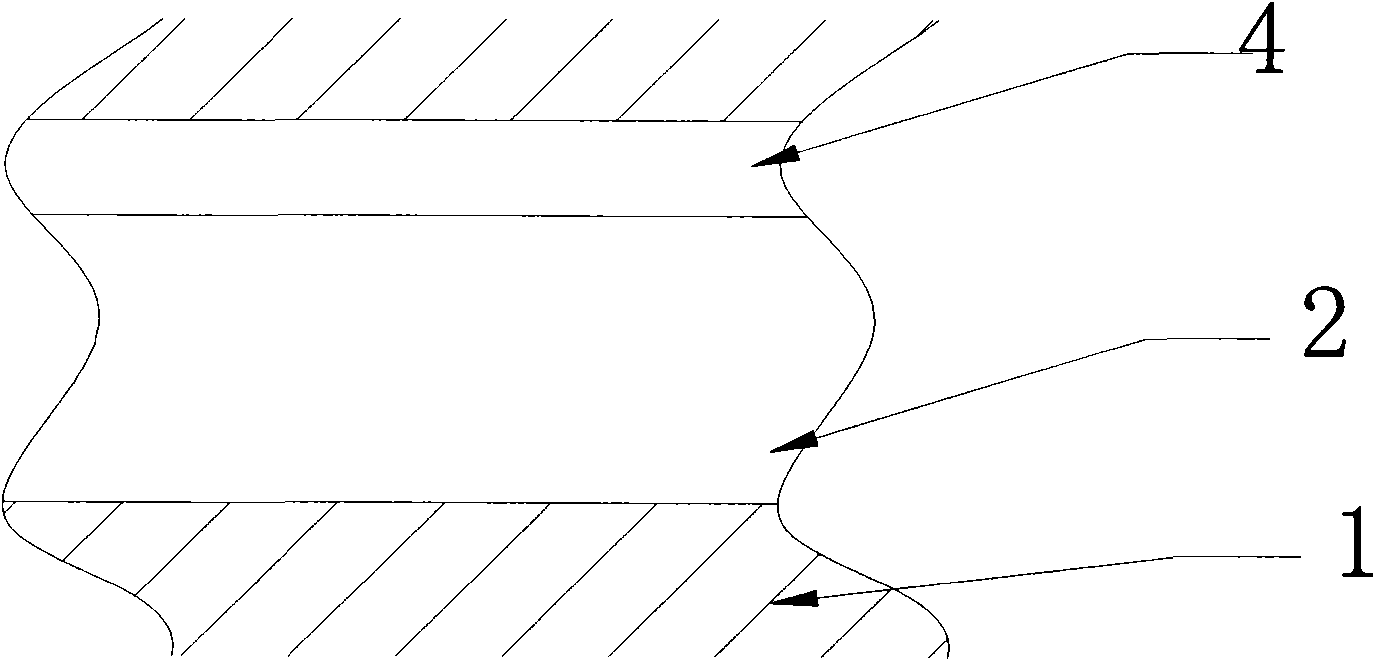

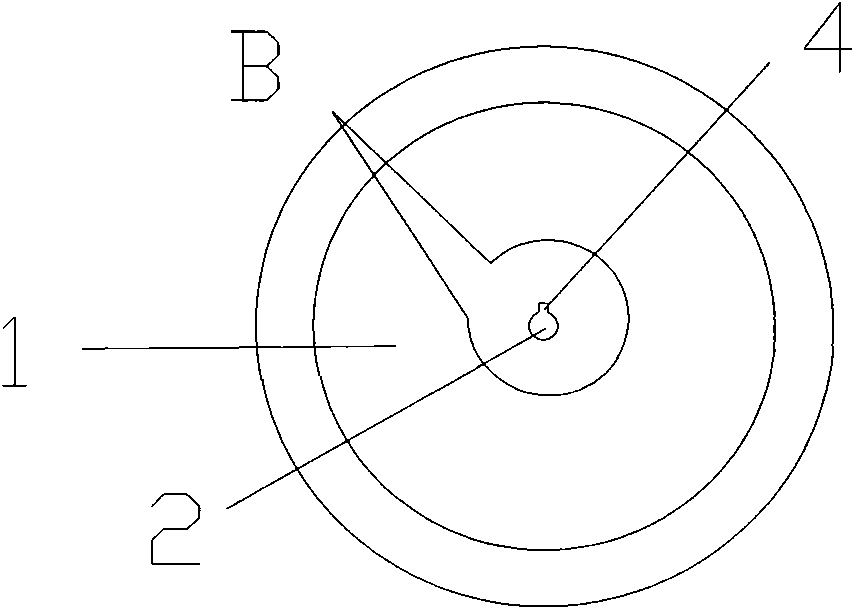

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] Ceramic ferrules are more precise than glass capillaries. The error of the aperture of the ordinary single-mode ceramic ferrule is +1 / -0 microns, and the diameter error of the single-mode fiber is less than 1 micron, so the common single-mode ceramic ferrule and the single-mode fiber are closely matched. The large number of applications of ceramic ferrules in optical fiber connectors makes the price very low, about 1 / 3 of the glass capillary. However, using the ceramic ferrule directly as a collimation device has an unsatisfactory optical coupling effect, even worse than that of a glass capillary. This is because when the two optical fibers are respectively inserted from both ends of the ferrule and aligned in the ferrule, the optical coupling matching liquid filled between the interface of the two optical fibers cannot exit due to the tight fit betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com