Multi-gas-source steam pipe network computing system of hydraulic thermal-coupling simulation model

A simulation model and simulation computing technology, which is applied in computing, special data processing applications, instruments, etc., can solve problems such as large errors, large data errors, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

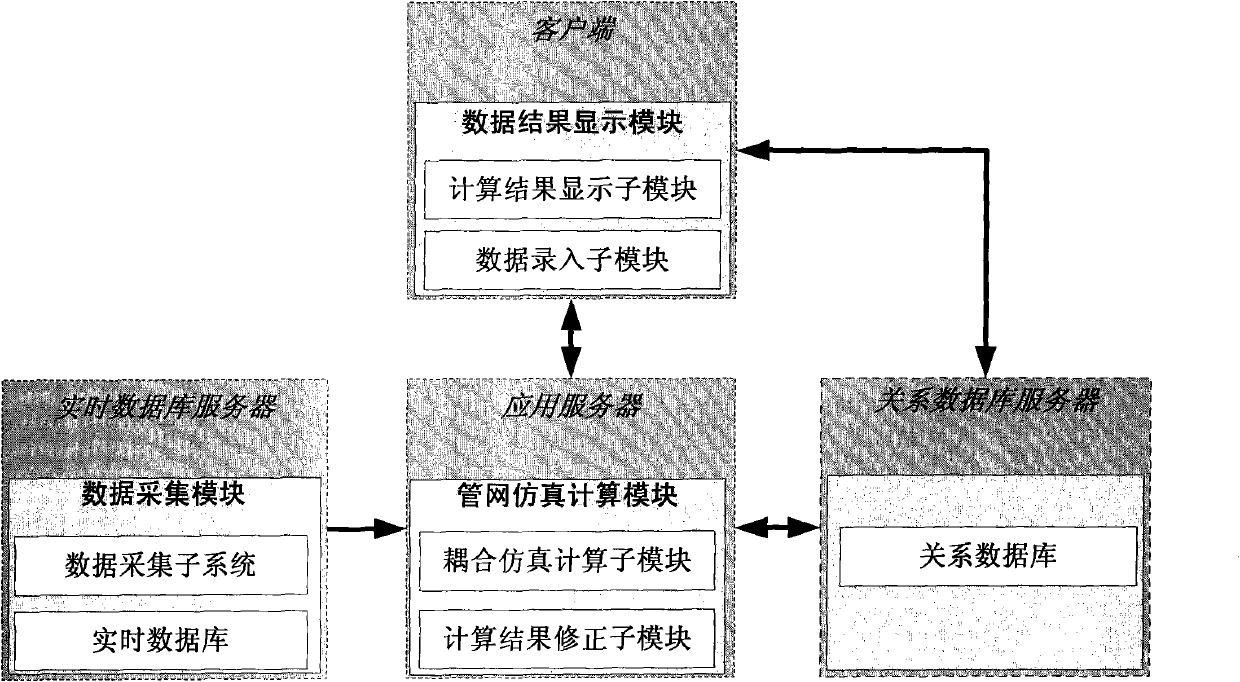

[0033] figure 1 It is a system and module relationship diagram of the present invention. It can be seen from the figure that this system mainly includes a relational database, a data acquisition module composed of a real-time database and a data acquisition subsystem, a data result display module composed of a data entry sub-module and a calculation result display sub-module, and a coupling simulation calculation sub-module. A pipe network simulation calculation module composed of modules and calculation result correction sub-modules. The data result display module is deployed on the client, the pipe network simulation calculation module is deployed on the application server, the relational database is deployed on the relational database server, and the data acquisition module is deployed on the real-time database server.

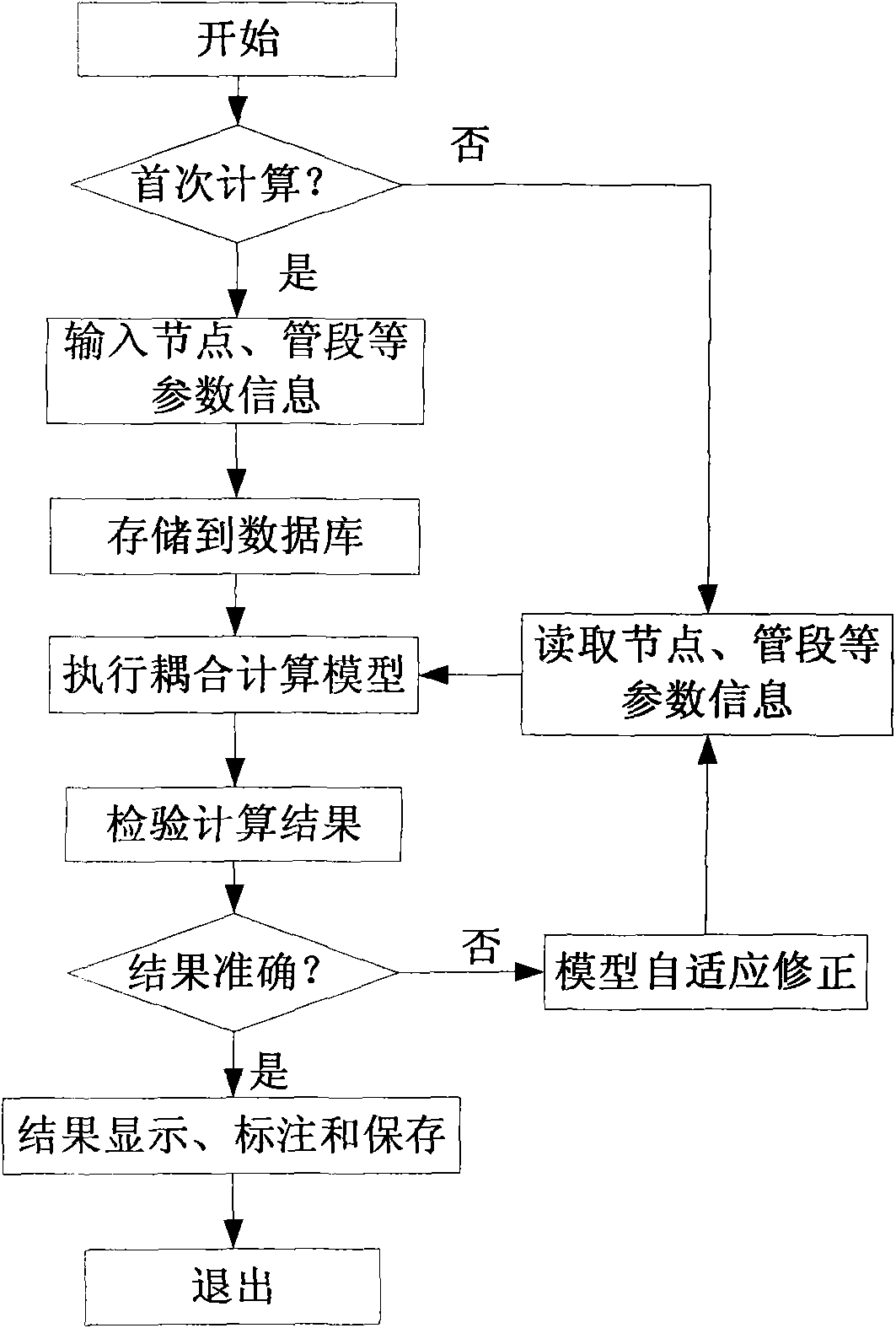

[0034] figure 2 It is a flow chart of the execution process of the pipe network simulation model. If it is not the first execution, first extract the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com