Cover plate structure of battery

A battery cover and substrate technology, which is applied to structural parts, battery pack components, circuits, etc., can solve the problems of complex procedures and poor sealing effect, and achieve the effects of simple procedures, prolonged service life, and avoidance of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

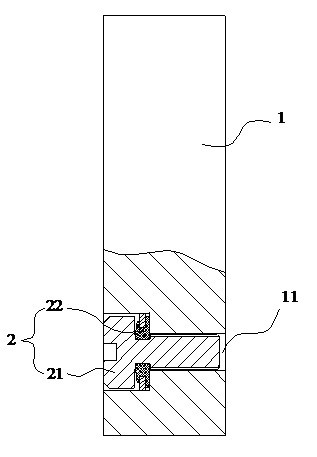

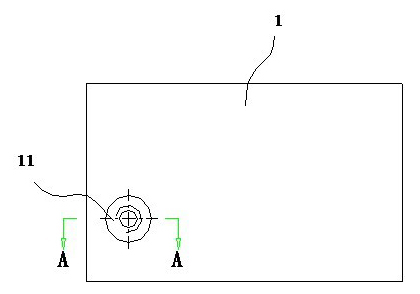

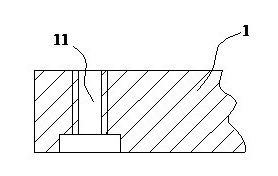

[0034] The threaded through hole 11 is also used as a liquid injection hole, and the electrolyte is injected into the battery case through the threaded through hole 11 .

[0035] When this structure is adopted, when the battery is formed, the screw 21 can be half-screwed into the threaded through hole 11, so that the screw 21 is in a half-tightened state; during the formation process, it is not necessary to use adhesive tape and cotton to seal the opening, and the sealing effect is good, and The process is simple and easy to operate; after the formation is completed, the screw 21 can be tightened directly, and the sealing ring 22 can seal the thread gap that may exist between the screw 21 and the liquid injection hole 11 under the pressure of the screw 21, and the sealing effect is good. The screw 21 resources can be reused, and the whole process does not need to remove the adhesive tape or cotton, which improves the production efficiency and avoids the defect of metal shell de...

Embodiment 2

[0038] Such as Figure 5 As shown, the substrate 1 is further provided with a liquid injection hole 12 for injecting liquid into the battery case. At this time, the liquid injection hole 12 is a conventional structure in the prior art, and is finally sealed by an interference-fit steel ball; the threaded through hole 11 is sealed and assembled by the sealing device 2 .

[0039] With the battery cover plate structure, due to the arrangement of the threaded through hole 11 and the sealing device 2, the air pressure inside the battery can be released, thereby avoiding problems such as battery bulging and explosion valves, and prolonging the service life of the battery.

Embodiment 3

[0041] Such as Image 6As shown, the substrate 1 is further provided with a liquid injection hole 13 , which has the same structure as the threaded through hole 11 and is also sealed and assembled by the sealing device 2 . With this structure, it has double safety protection functions of both explosion-proof and pressure relief.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com