Temperature-adjusting negative magnetic permeability element based on liquid crystal and preparation method thereof

A negative permeability, liquid crystal technology, applied in waveguide devices, instruments, resonators, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of dynamically adjustable operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

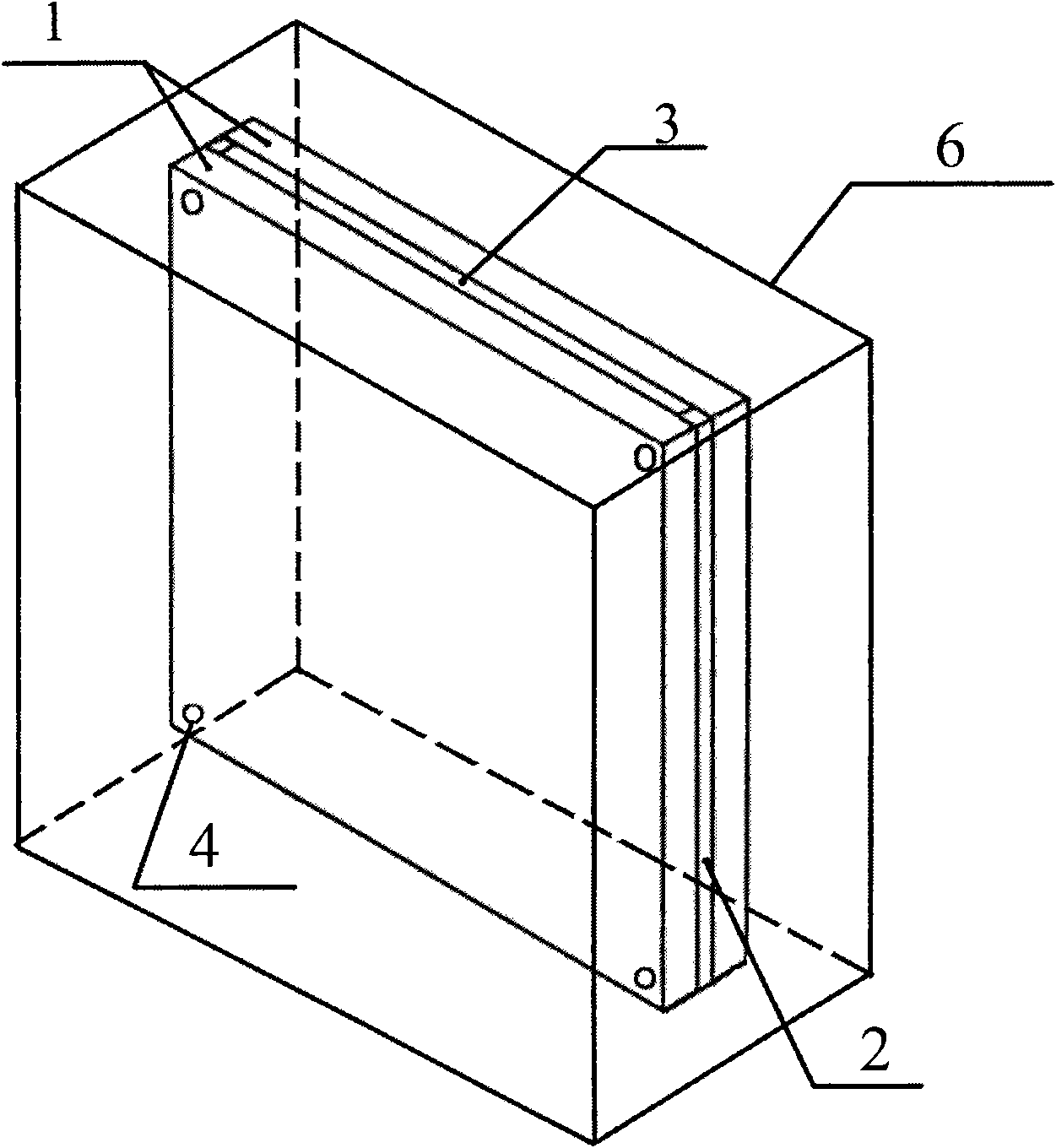

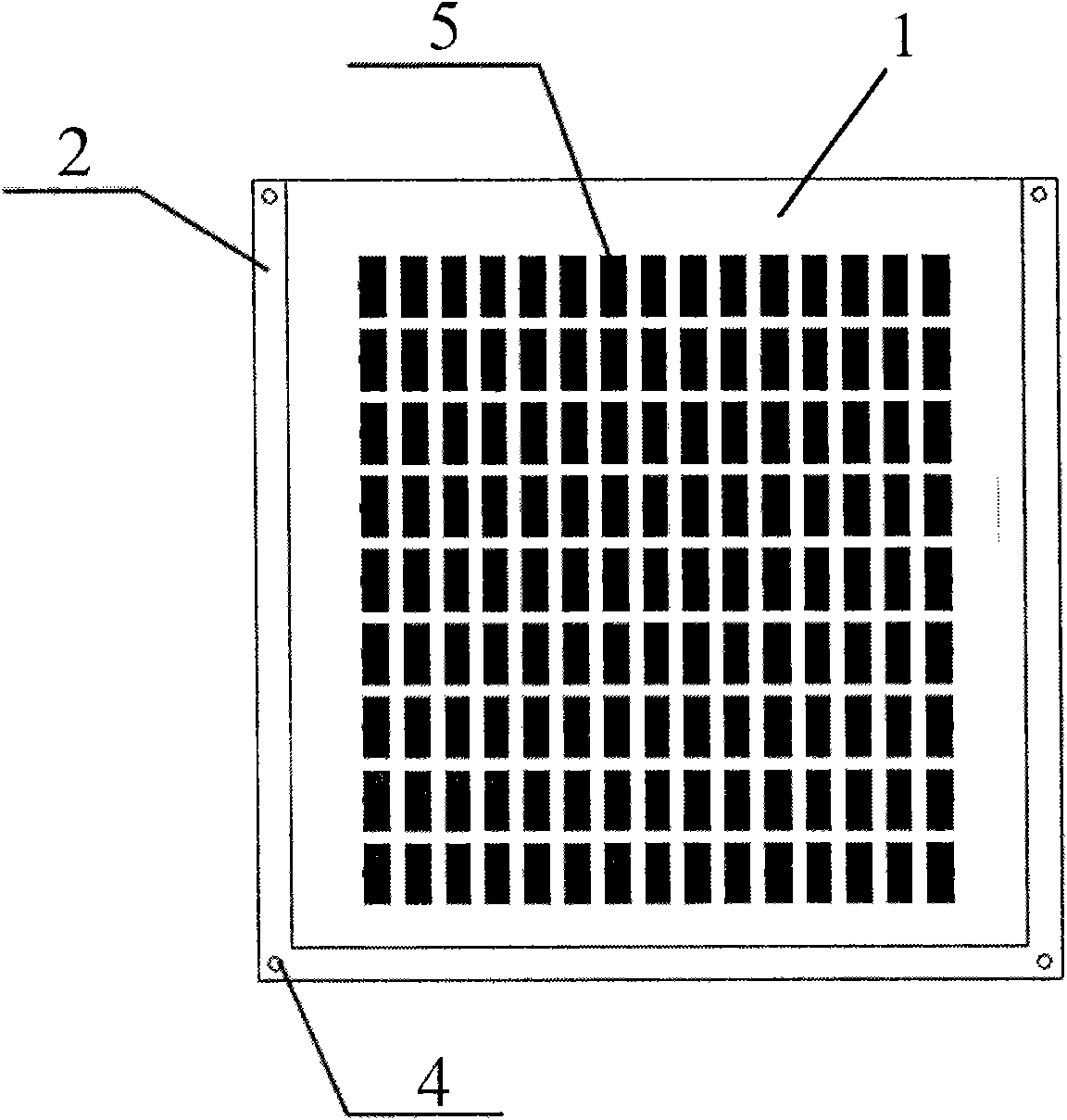

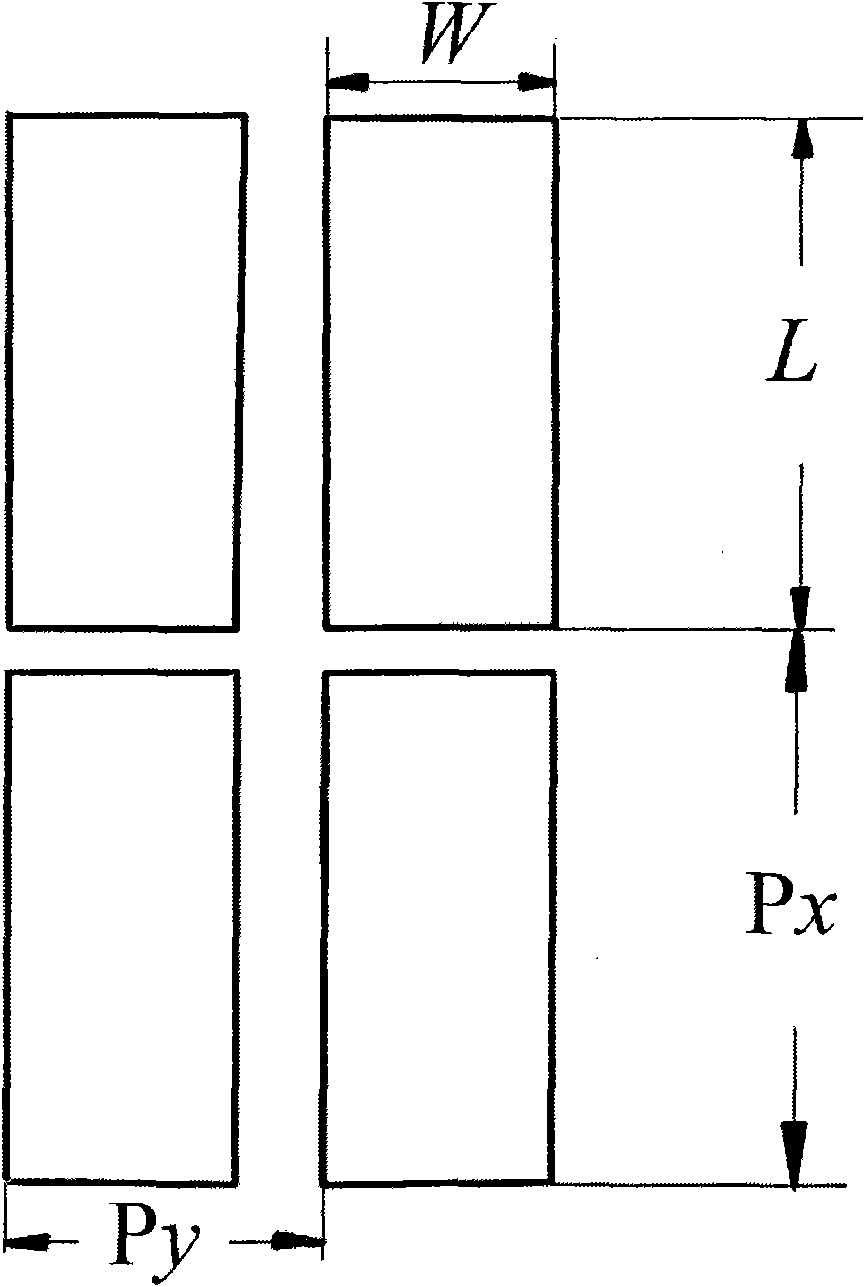

[0048] Embodiment 1: Using circuit board printing technology to etch a rectangular metal sheet 5 array on one side of a copper clad laminate 1 with a thickness of 1.00mm, the size of the metal sheet 5 is: W=4.00mm, L=9.00mm, Px=11.00mm , Py=6.00mm. Positioning holes 4 with a diameter of 1.00 mm are machined at the four corners of the copper clad laminate 1 . An epoxy glass plate with a thickness of 0.50 mm and the same size as the copper clad laminate 1 is selected, and a U-shaped bead 2 with a side width of 5.00 mm and a positioning hole 4 is prepared by using a numerical control machine tool. A polyimide liquid crystal aligning agent is coated on the side of the copper clad plate 1 with a metal sheet array by the spin coating method, and a film is formed by thermal curing by a stepwise heating method, and the polyimide film is oriented and rubbed with a dust-free cloth to obtain A polyimide liquid crystal alignment layer that aligns liquid crystal molecules vertically.

[...

Embodiment 2

[0052] Example 2: An array of rectangular metal sheets 5 is prepared on a copper clad laminate 1 with a thickness of 1.00mm by using circuit board printing technology. The size of the metal sheets is: W=3.00mm, L=8.00mm, Px=12.00mm, Py=5.00 mm, while machining positioning holes 4 with a diameter of 1.00 mm at the four corners of the copper clad laminate 1 . Select an epoxy glass plate with a thickness of 0.40 mm and the same size as the copper-clad laminate 1, and use a CNC machine tool to prepare a U-shaped bead 2 with a side width of 5.00 mm, and machine the four corners of the U-shaped bead 2 into a positioning plate with a diameter of 1.00 mm. hole. A polyimide liquid crystal aligning agent is coated on the side of the copper-clad laminate 1 with a metal sheet array by the spin coating method, and a film is formed by thermal curing by a stepwise heating method, and the polyimide film is oriented and rubbed with a dust-free cloth to obtain A polyimide liquid crystal alignm...

Embodiment 3

[0056] Embodiment 3: An array of circular metal sheets 5 is prepared on a copper clad laminate 1 with a thickness of 1.00 mm by circuit board printing technology, and positioning holes 4 with a diameter of 1.00 mm are machined at the four corners of the copper clad laminate 1 . The dimensions of the circular metal sheet 5 are: R=3.50mm, Px=11.00mm, Py=11.00mm. An epoxy glass plate with a thickness of 0.60 mm and the same size as the copper clad laminate 1 is selected, and a U-shaped bead 2 with a side width of 5.00 mm and a positioning hole 4 is prepared by using a numerical control machine tool. A polyimide liquid crystal aligning agent is coated on the side of the copper clad plate 1 with a metal sheet array by the spin coating method, and a film is formed by thermal curing by a stepwise heating method, and the polyimide film is oriented and rubbed with a dust-free cloth to obtain A polyimide liquid crystal alignment layer that aligns liquid crystal molecules vertically.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pretilt | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com