Liquid crystal-based broadband electric field-adjusted negative refractive index device and manufacturing method thereof

A technology with adjustable negative and refractive index, applied in instruments, polarizing elements, optics, etc., can solve the problem of inability to meet the application requirements of negative refractive index materials, and achieve the effect of improving the working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

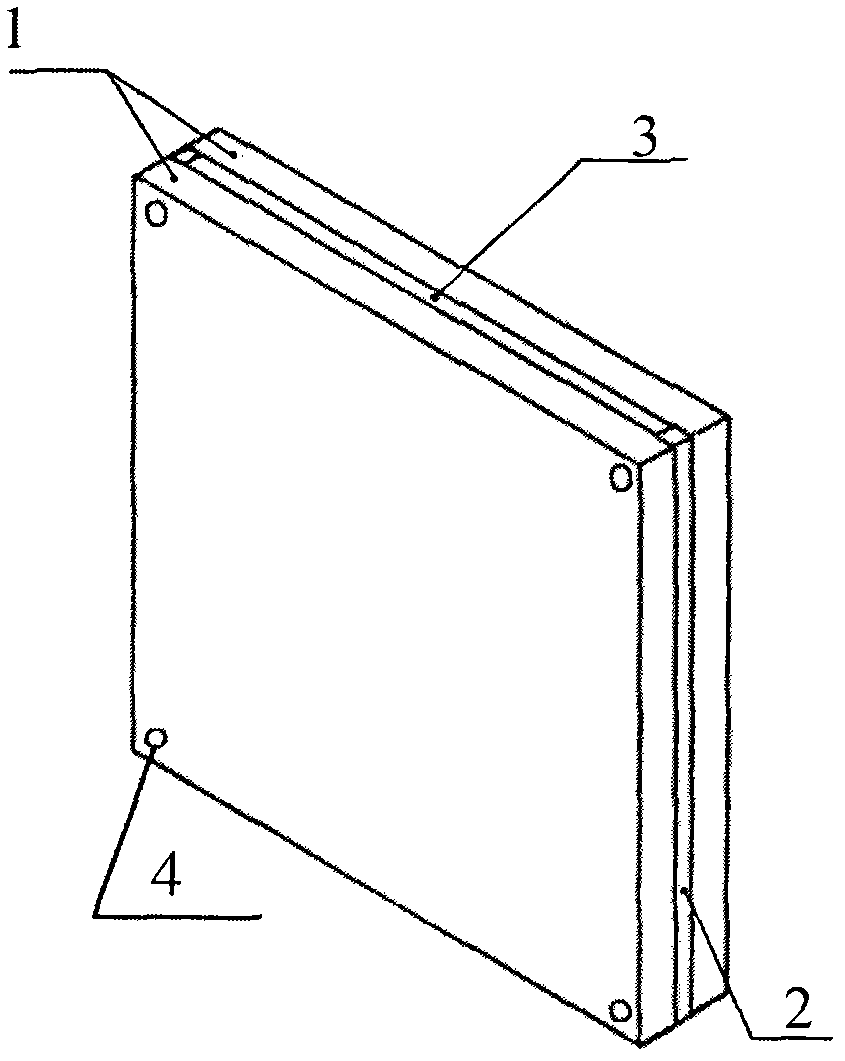

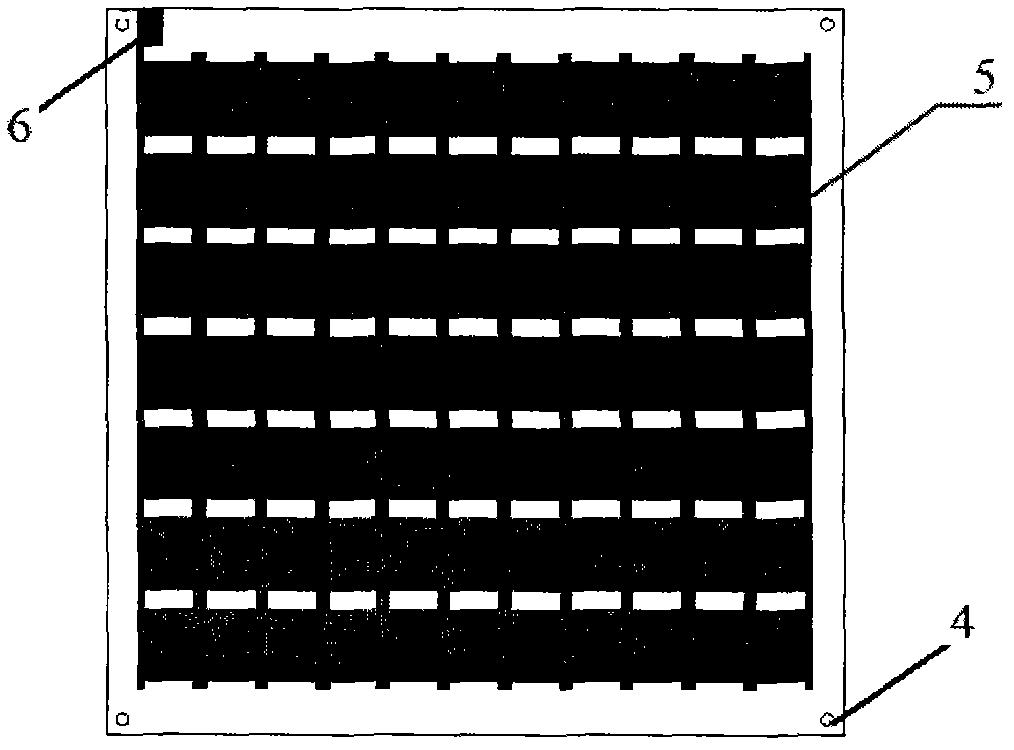

[0041] Embodiment 1: Utilize circuit board printing technology to etch the metal sheet 5 array and lead wire 6 of fishnet structure on one side of the copper clad laminate 1 with a thickness of 1.00mm, the size of the metal sheet 5 is: W=8.00mm, L=12.00mm , Px=15.00mm, Py=10.00mm. Positioning holes 4 with a diameter of 1.00 mm are machined at the four corners of the copper clad laminate 1 . An epoxy glass plate with a thickness of 0.50 mm and the same size as the copper clad laminate 1 is selected, and a U-shaped bead 2 with a side width of 5.00 mm and a positioning hole 4 is prepared by using a numerical control machine tool. Coat the polyimide liquid crystal aligning agent arranged along the surface on the side of the copper-clad laminate 1 with the metal sheet array by the spin coating method, heat-cure the film by step heating method, and use a dust-free cloth on the polyimide film along the Orientation rubbing in the direction of the electrodes to obtain a polyimide liqu...

Embodiment 2

[0045] Example 2: A metal sheet 5 array and lead wires 6 with a fishnet structure are prepared on a copper clad laminate 1 with a thickness of 1.00mm by circuit board printing technology. The size of the metal sheet is: W=6.00mm, L=10.00mm, Px=15.00 mm, Py=8.00mm. At the same time, positioning holes 4 with a diameter of 1.00 mm are machined at the four corners of the copper clad laminate 1 . Select an epoxy glass plate with a thickness of 0.40 mm and the same size as the copper-clad laminate 1, and use a CNC machine tool to prepare a U-shaped bead 2 with a side width of 5.00 mm, and machine the four corners of the U-shaped bead 2 into a positioning plate with a diameter of 1.00 mm. hole. Coat the polyimide liquid crystal aligning agent arranged along the surface on the side of the copper-clad laminate 1 with the metal sheet array by the spin coating method, heat-cure the film by step heating method, and use a dust-free cloth on the polyimide film along the Orientation rubbin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com