DC-DC converter with snubber circuit

A DC-DC, buffer circuit technology, applied in the direction of adjusting electrical variables, output power conversion devices, converting DC power input to DC power output, etc., can solve problems such as damage, achieve damage prevention, high-speed action, and reduce impulse voltage and the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

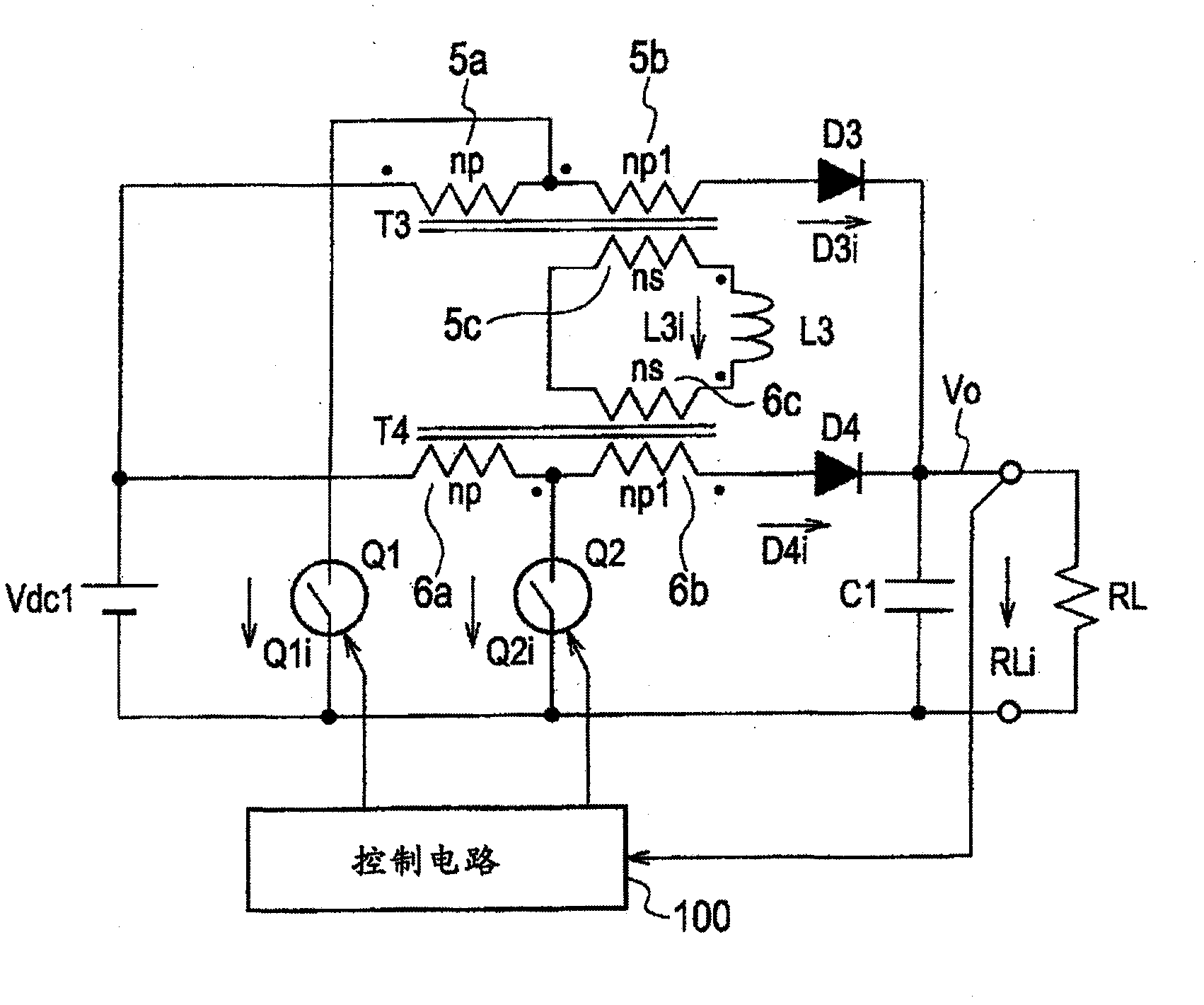

[0043] figure 2 It is a circuit configuration diagram showing the DC-DC converter with the snubber circuit of the first embodiment. figure 2 The shown DC-DC converter with a snubber circuit is composed of a multi-phase transformer-linked (Trans-Linked) step-up chopper circuit.

[0044] A DC-DC converter with a snubber circuit includes a DC power supply Vi, a transformer T1 (first transformer), a transformer T2 (second transformer), a reactor Lr1 (first reactor), a reactor Lr2 (second reactor), Reactor L1 (third reactor), switch Tr1 (first switch), switch Tr2 (second switch), diode D1, diode D2, diode D3, diode D4, snubber diode Ds1 (first snubber diode), snubber diode Ds2 (second snubber diode), snubber resistor Rs, snubber capacitor Cs, smoothing capacitor Co, and control circuit 10 .

[0045] The transformer T1 has a primary coil 1a (number of turns n1), a booster coil 1b (number of turns n3), and a secondary coil 1c (number of turns n2) electromagnetically coupled to th...

Embodiment 2

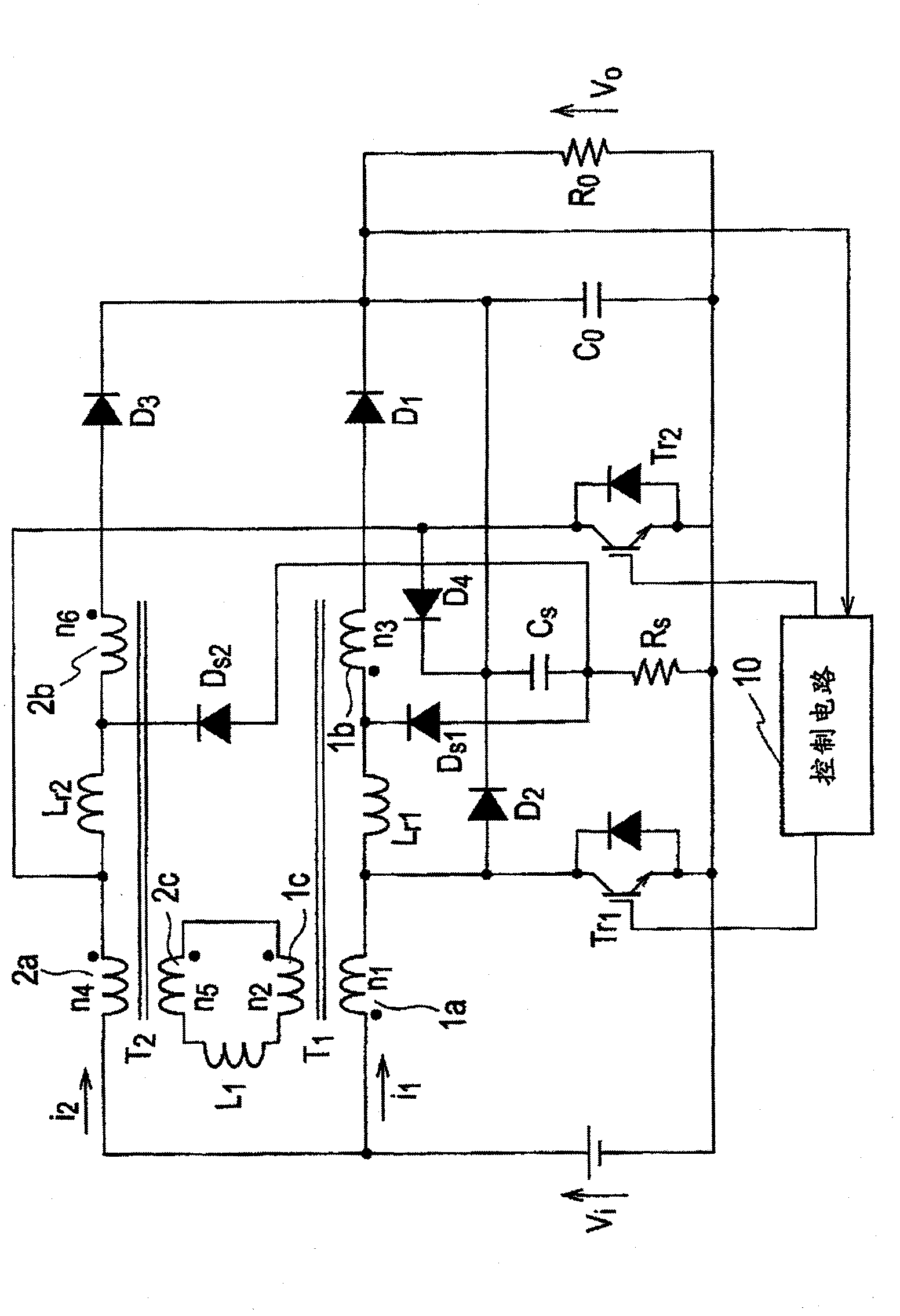

[0069] Figure 13 It is a circuit configuration diagram showing a DC-DC converter with a snubber circuit according to the second embodiment. In Embodiment 1, the reactor Lr1 is connected in series to the lifting coil 1b, and the reactor Lr2 is connected in series to the lifting coil 2b. Embodiment 2 is characterized in that the reactor Lr1 is connected in series to the switch Tr1, and the reactor Lr2 is connected in series to the switch Tr2.

[0070] The structure of the snubber circuit composed of snubber capacitor Cs, snubber resistor Rs, snubber diode Ds1, and snubber diode Ds2 is due to the figure 2 The structure of the illustrated embodiment 1 is the same, so the description is omitted.

[0071] Here, the operation and effect of the DC-DC converter having a snubber circuit when the reactors Lr1 and Lr2 are connected in series to the switches Tr1 and Tr2 will be described.

[0072] First, the switch Tr1 is turned on according to a gate signal from the switch Tr1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com