Self-propelled onion mulching film recoverer

A self-propelled, recycling machine technology, applied in the direction of collectors, agricultural machinery and implements, applications, etc., can solve the problems of poor accuracy, low film recovery rate and operating efficiency, and achieve the effect of improving operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

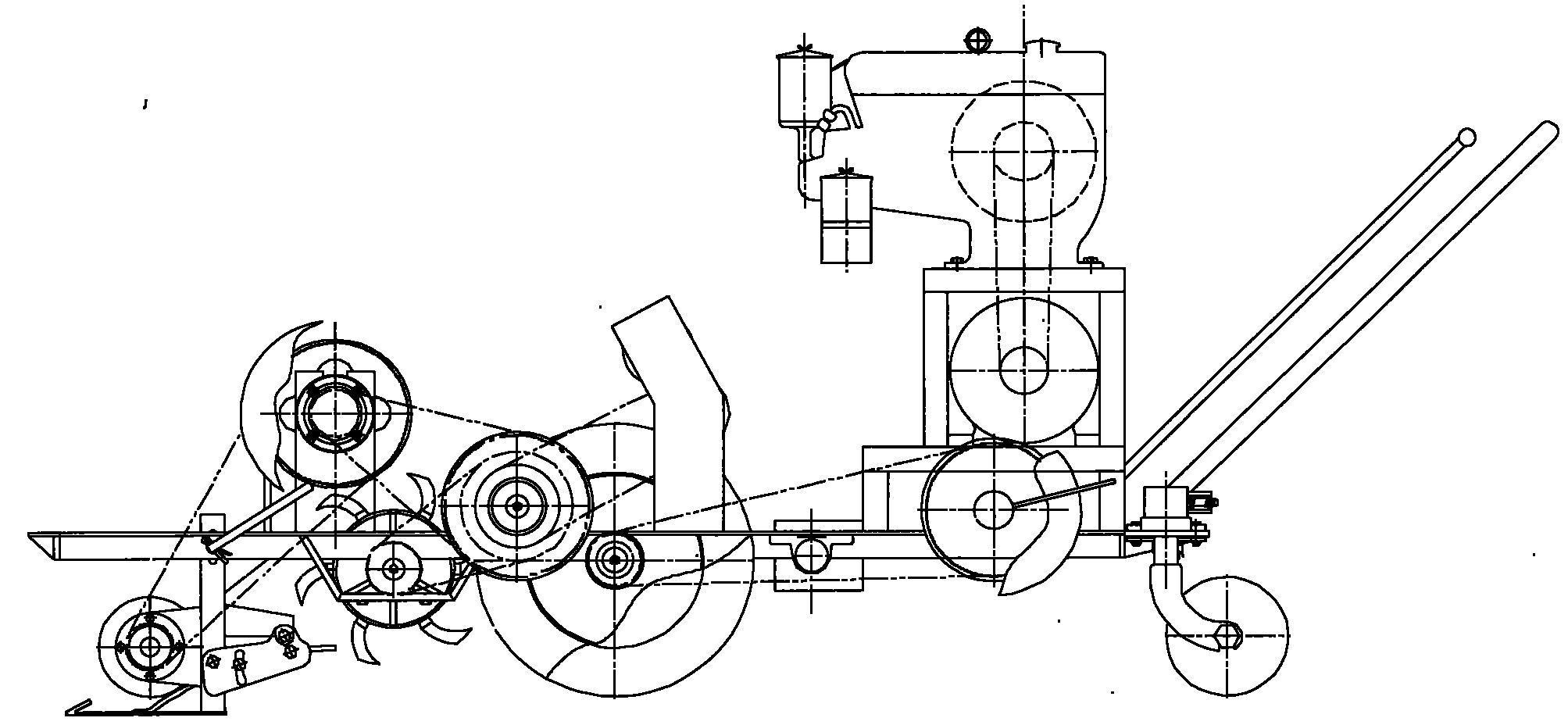

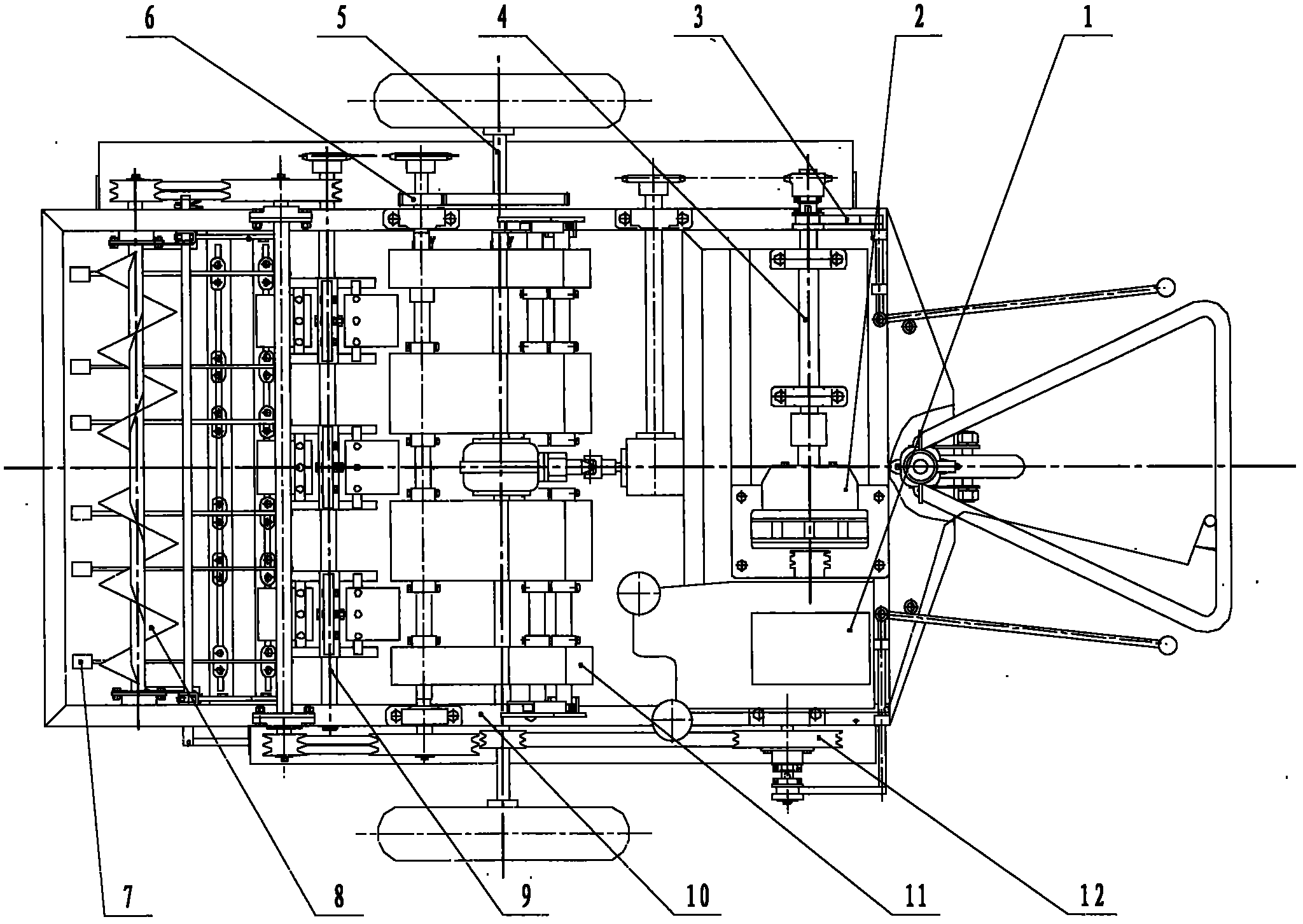

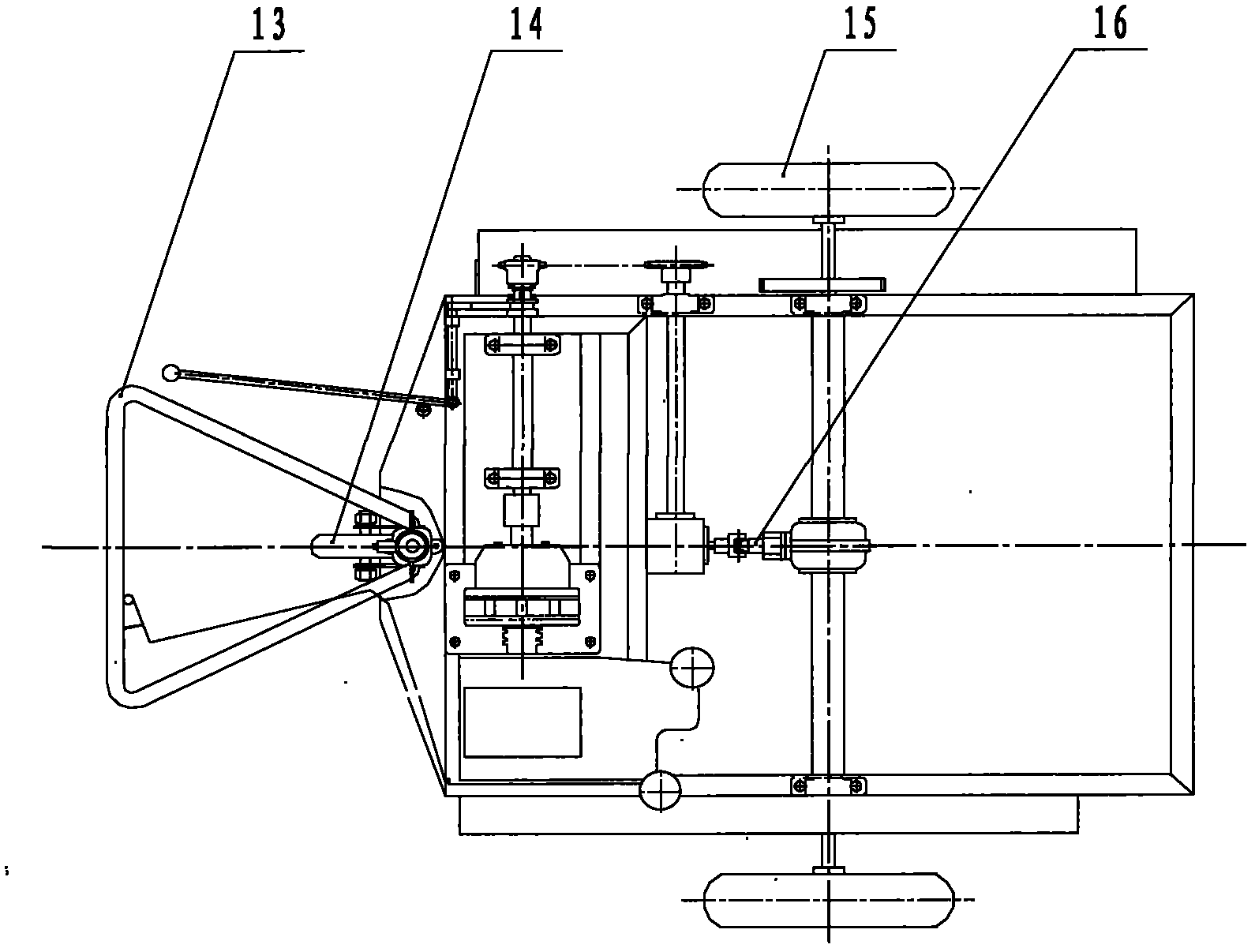

[0040] exist figure 1 with figure 2 In the shown embodiment, before the operation of the machine, first move the handle, loosen the pair of clutch discs of the power separation device (3) that controls the power transmission, and start the power device (1) of the machine. The pair of clutch discs of the power clutch device are combined, and the power is transmitted to the walking chassis (5) through the reducer (2), the intermediate transmission shaft (4) and the power clutch device, thereby driving the whole machine to move forward, and the walking chassis Through the transmission system (6) of the machine, the power is transmitted to each functional mechanism and system of the machine on the installation frame (10). Shovel loosen the compacted soil clods on both edges of the plastic film in the onion pool, and pick the plastic film into the machine body with the film picker in front of it, remove the small soil particles carried on the surface of the plastic film by the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com