Lifting and swiveling structure

A technology of lifting and rotating and steel balls, which is applied to stools, other seating furniture, household appliances, etc., can solve problems such as rust, waste of materials, lifting and rotating problems, and achieve convenient use, long service life and structural design simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

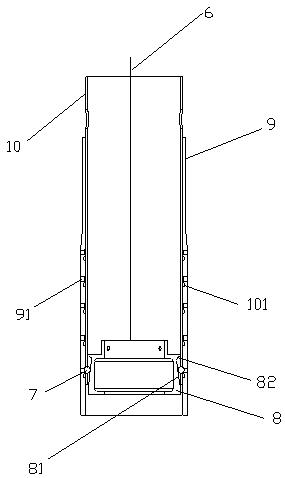

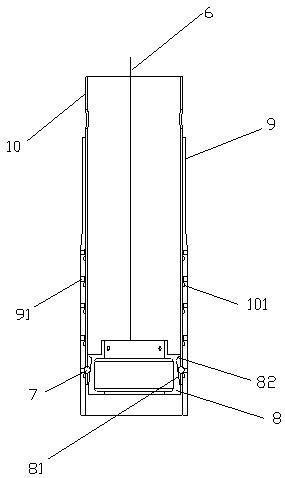

[0016] Such as figure 1 , the lifting and rotating structure includes a traction component 6, a steel ball 7, a steel ball locking disc 8, a base sleeve 9, and a steel ball locking sleeve 10; the traction component 6 is connected with the steel ball locking disc 8, and the base sleeve 9 is Cylindrical sleeves with upper and lower openings, the base sleeve 9 is set outside the steel ball locking sleeve 10; The hole 91 of the steel ball locking disc 8 is set in the steel ball locking sleeve 10, the steel ball 7 is provided on the ramp 81 of the steel ball locking disc 8, and the steel ball locking sleeve 10 is located at the bottom of the same horizontal plane. The hole 101 matched with the steel ball 7 is provided with a groove 82 on the upper part of the steel ball locking disc 8 . The base sleeve 9 has five holes 91 in the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com