Process for painting furniture

A paint and craft technology, applied in the field of furniture paint craftsmanship, can solve the problems of high cost, insufficient paint, water and air pollution, etc., and achieve the effects of high paint utilization, less pollution, and simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

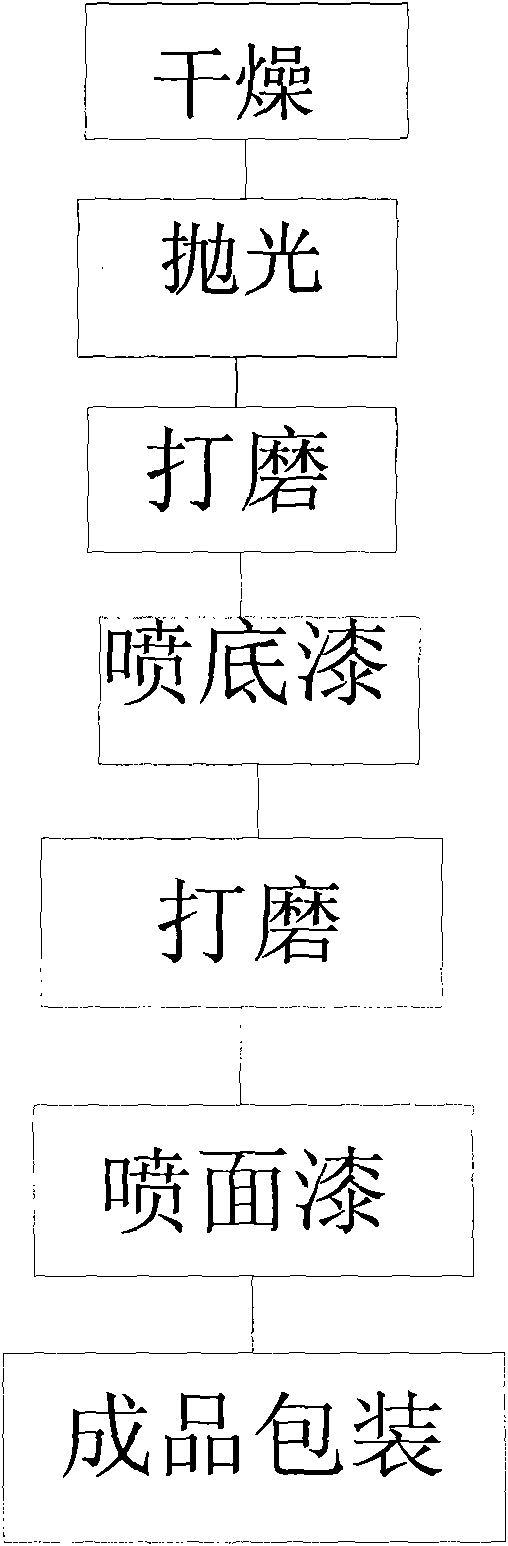

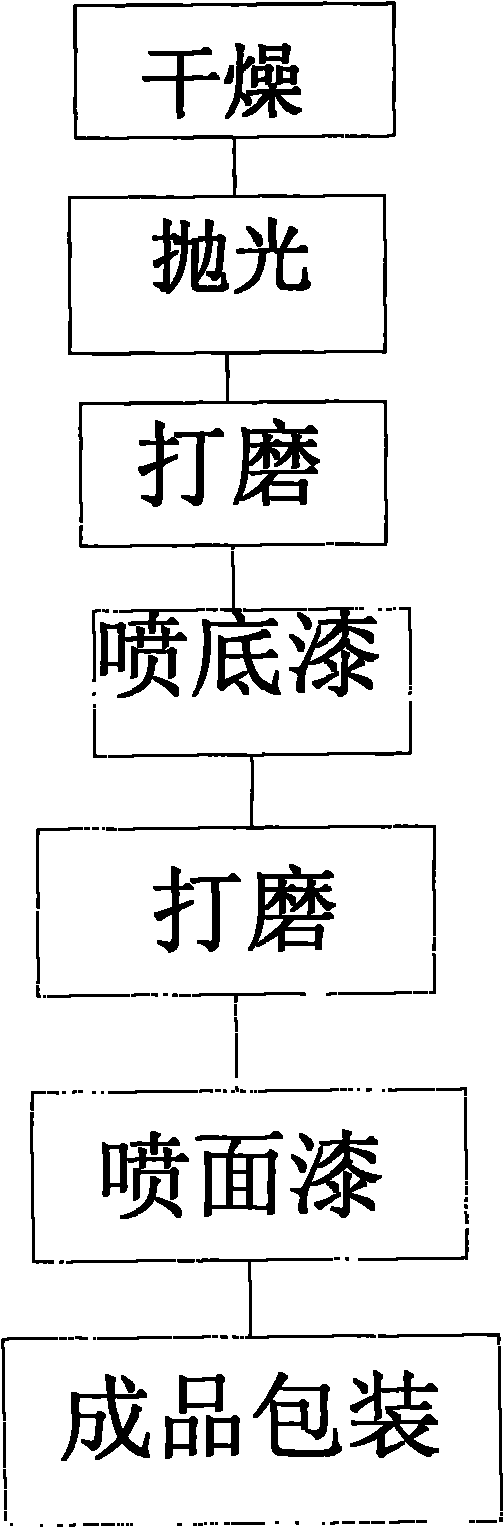

Image

Examples

Embodiment 1

[0028] A paint process for furniture, comprising the following process steps:

[0029] (1) Drying treatment: Drying treatment after opening the base material, including:

[0030] (11) After raw materials are opened, they should be processed immediately, and the sawdust should be cleaned up, put on the shelves neatly, and dried in the cellar;

[0031] (12) Squeeze water vapor into the drying cellar and cook for 12 hours;

[0032] (13) High-temperature drying treatment for 24 days; the moisture content of the substrate dried at high temperature in step (13) is 9%.

[0033] (14) After the base material is taken out of the cellar, it should be placed in a cool place to regain moisture naturally. After the base material described in step (14) is left out of the cellar, it should be placed in a cool place to regain moisture naturally, and the moisture content will reach 14%.

[0034] (2) polishing;

[0035] (3) Grinding: Grinding with fine sandpaper to smooth the surface of the s...

Embodiment 2

[0041] A paint process for furniture, comprising the following process steps:

[0042] (1) Drying treatment: Drying treatment after opening the base material, including:

[0043] (11) After raw materials are opened, they should be processed immediately, and the sawdust should be cleaned up, put on the shelves neatly, and dried in the cellar;

[0044] (12) Squeeze water vapor into the drying cellar and cook for 18 hours;

[0045] (13) High-temperature drying treatment for 24 days to one day; the moisture content of the substrate dried at high temperature in step (13) is 10%.

[0046] (14) After the base material is taken out of the cellar, it should be placed in a cool place to regain moisture naturally. After the base material described in step (14) is left out of the cellar, it should be placed in a cool place to regain moisture naturally, and the moisture content will reach 14%.

[0047] (2) polishing;

[0048] (3) Grinding: Grinding with fine sandpaper to smooth the surf...

Embodiment 3

[0054] A paint process for furniture, comprising the following process steps:

[0055] (1) Drying treatment: Drying treatment after opening the base material, including:

[0056] (11) After raw materials are opened, they should be processed immediately, and the sawdust should be cleaned up, put on the shelves neatly, and dried in the cellar;

[0057] (12) Squeeze water vapor into the drying cellar and cook for 15 hours;

[0058] (13) High-temperature drying treatment for 24 days; the moisture content of the substrate dried at high temperature in step (13) is 9%.

[0059] (14) After the base material is taken out of the cellar, it should be placed in a cool place to regain moisture naturally. After the base material described in step (14) is left out of the cellar, it should be placed in a cool place to regain moisture naturally, and the moisture content will reach 10%.

[0060] (2) polishing;

[0061] (3) Grinding: Grinding with fine sandpaper to smooth the surface of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com