Device for processing long shaft

A processing device and long axis technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of difficult to guarantee the long axis, easy to bend, difficult to ensure the straightness of the long axis, etc., so as to ensure the processing quality , length extension, to achieve the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

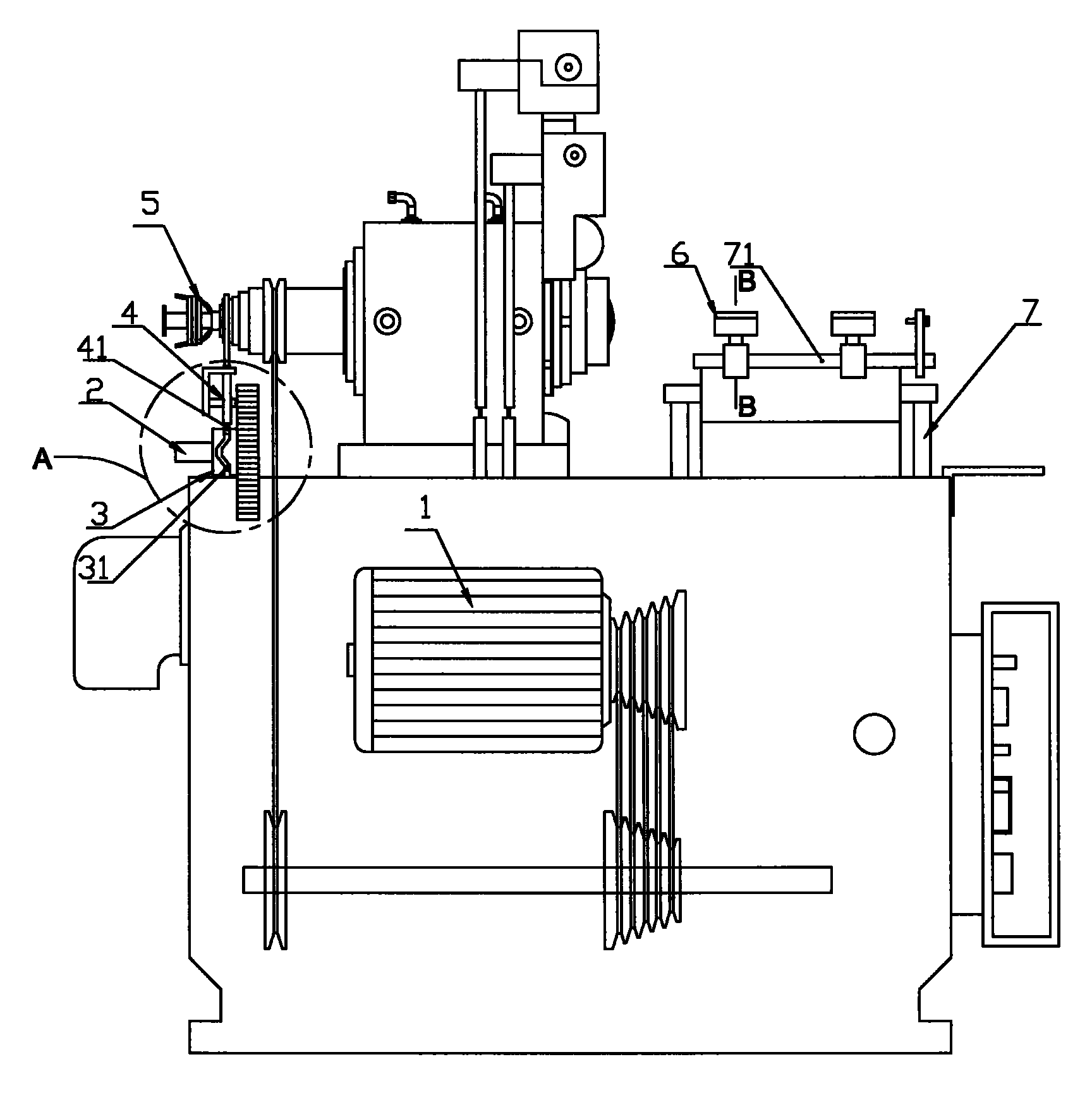

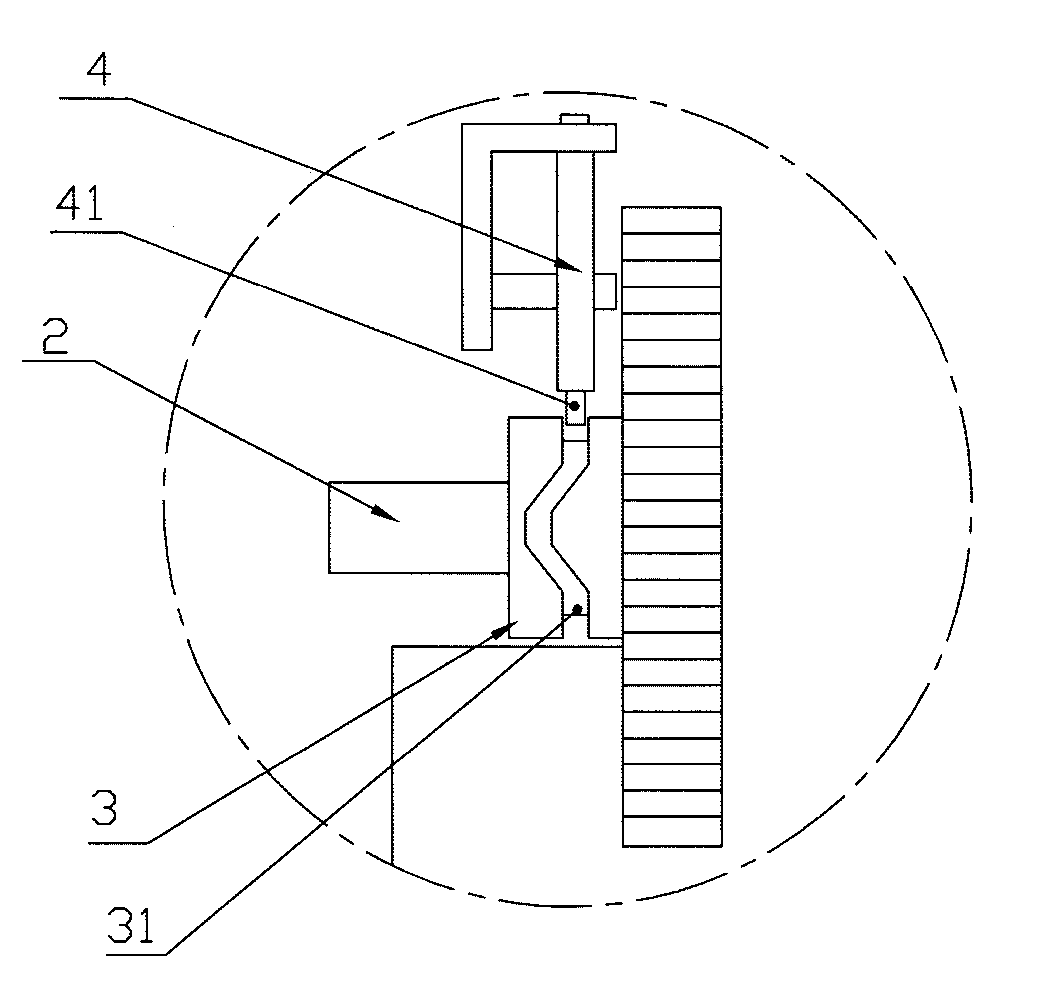

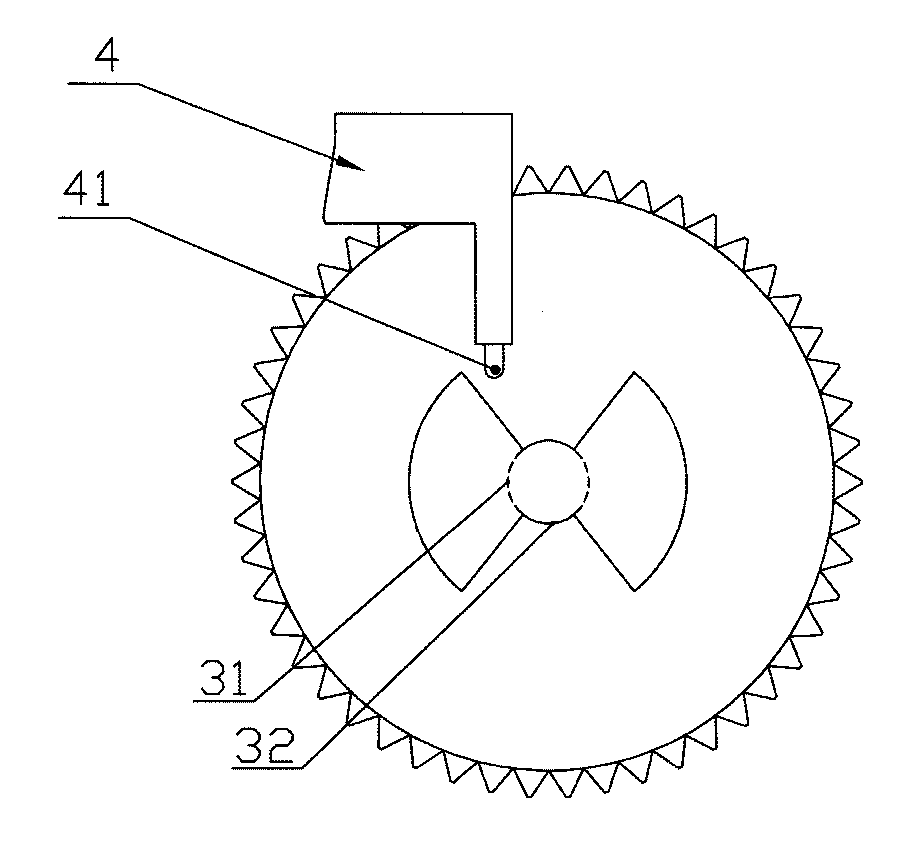

[0014] Embodiment: A long-axis processing device, based on the direction of use, the motor 1 rotates with the camshaft 2, the opening control cam 3 is fixedly sleeved on the outside of the camshaft 2, and the opening control switch 4 is hinged on the machine bed. The contact 41 at one end tightly pushes against the outer surface of the clamp opening control cam 3 in the circumferential direction, and the other end is movably sleeved on the outer surface of the jaw 5 which is a truncated cone-shaped surface on the outer surface of the circumferential direction. It is characterized by: the clamp opening control cam 3 The outer surface of the circumferential direction is provided with at least two sections of V-shaped curved grooves 31 with the same opening direction in the axial direction, and the V-shaped curved grooves 31 on the outer surface of the clamping control cam 3 in the circumferential direction are smooth with the same outer diameter. The arc surface 32, the smooth ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com