Measuring method for non-contact steel rail sagging surface

A measurement method and non-contact technology, which can be used in measurement devices, railway vehicle shape measuring instruments, photogrammetry/video surveying, etc., and can solve problems such as low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

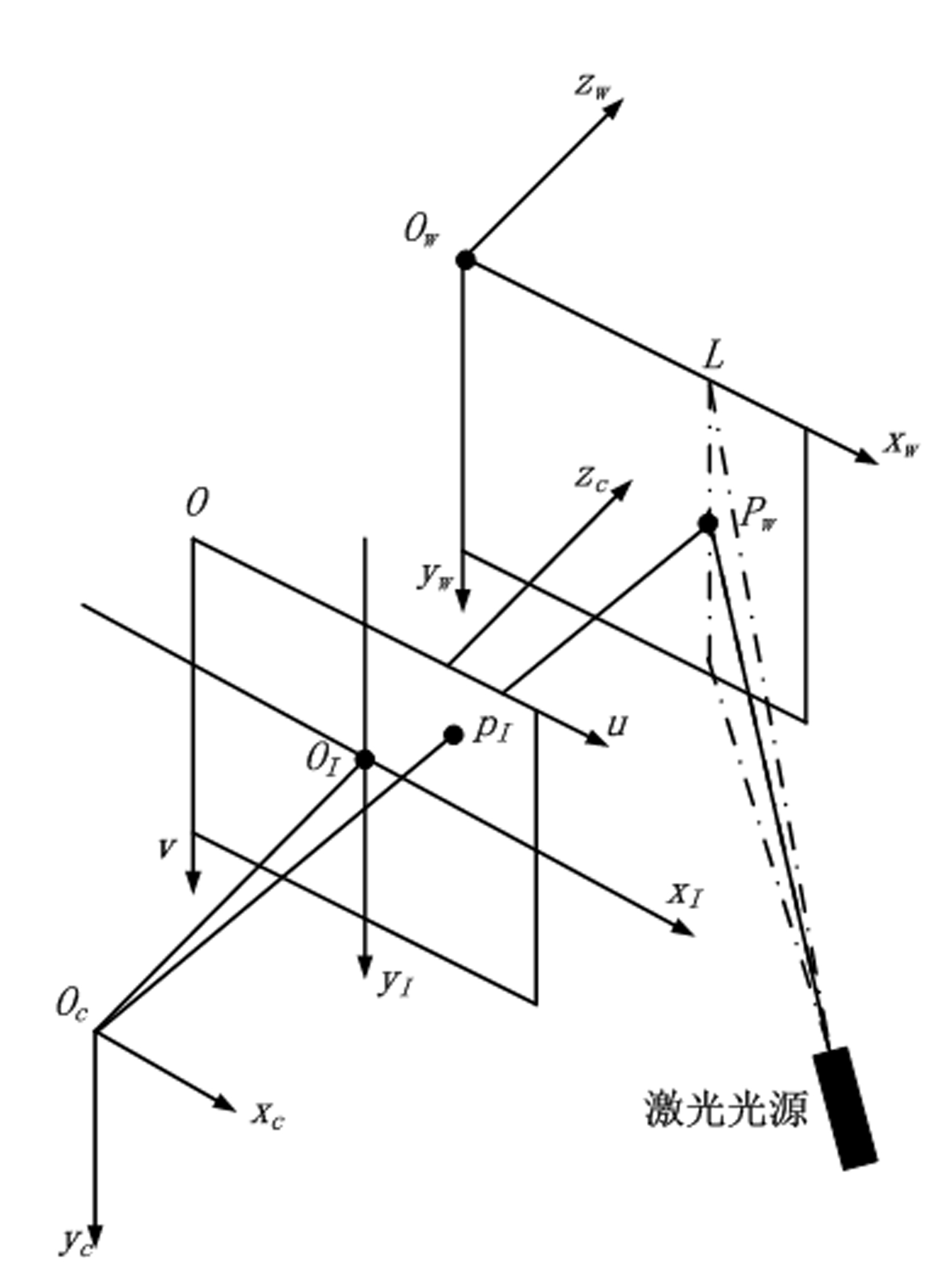

[0023] Such as figure 1 As shown, the camera 3D vision measurement model is usually based on the pinhole model. The world coordinate system is consistent with the sensor light plane coordinate system, set to O w -x w the y w z w , its O w -x w the y w coincides with the light plane. The image plane coordinate system is O I -X I Y I , where O I is the intersection of the optical axis and the image plane, and is the optical center of the image plane. o I and O c The distance f between them is the effective focal length of the objective lens imaging. where O I x I axis along the pixel lateral direction, O I Y I axis perpendicular to O I x I axis. In computer graphics, the point in the upper left corner is usually used as the origin of the image coordinates, that is, figure 1 The point O in is the origin to establish the image coordinate system Ouv. Computer Image Coordinate System Ouv and O I -X I Y I Coplanar, Ouv is O I -X I Y I along O I O obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com