Packing box base plate for automotive rims

A technology for automobile rims and packaging boxes, which is applied in the directions of packaging, transportation and packaging, rigid containers, etc., can solve the problems of high cost, bumped automobile rims, inconvenient handling, etc., and achieves convenient placement, convenient loading and unloading, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the drawings:

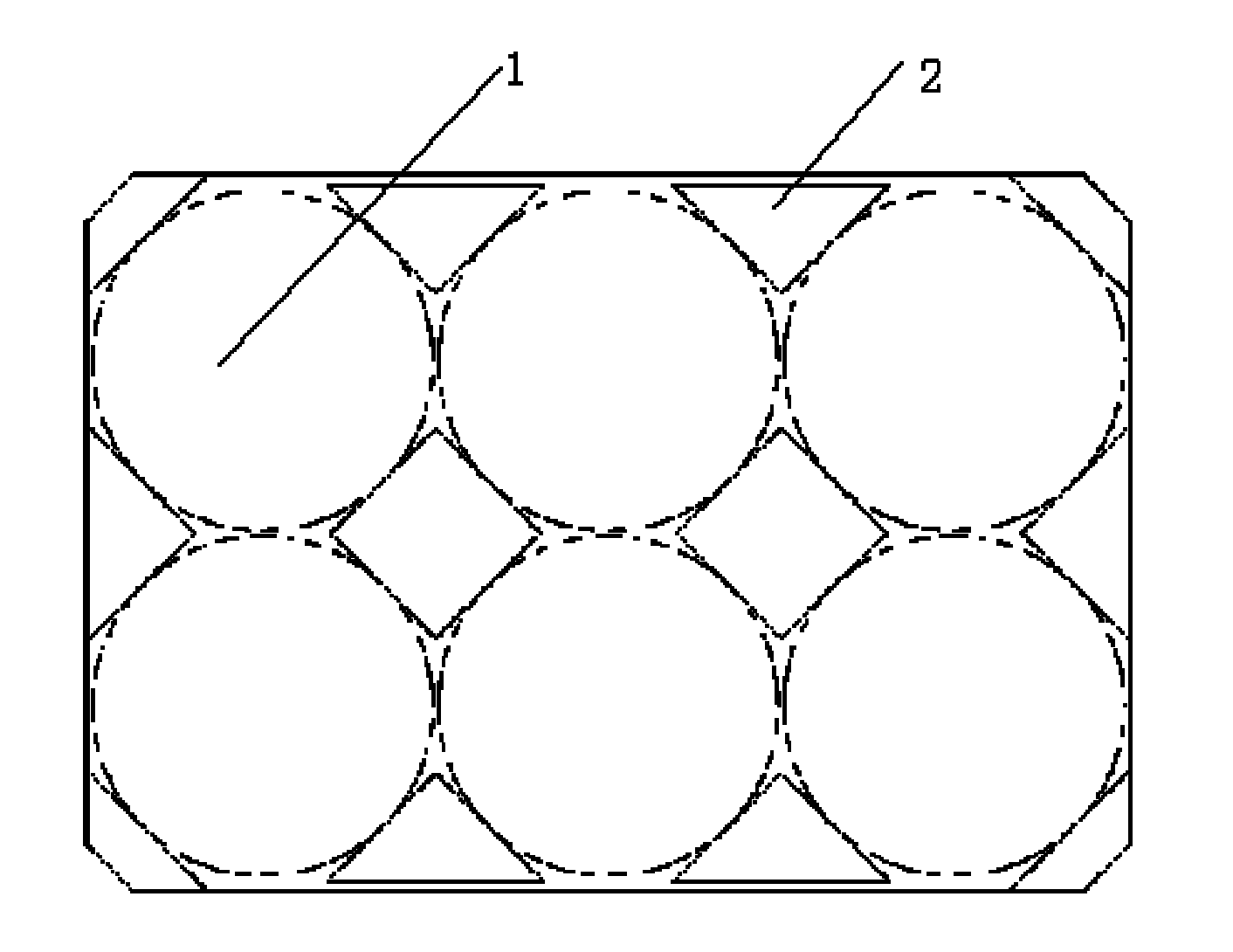

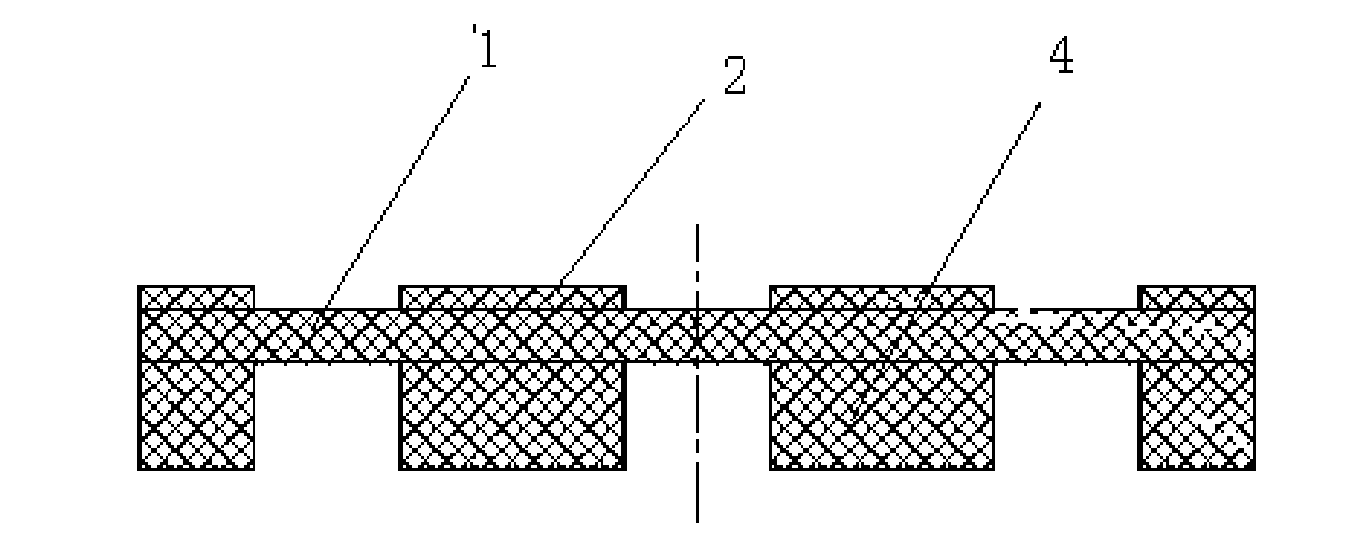

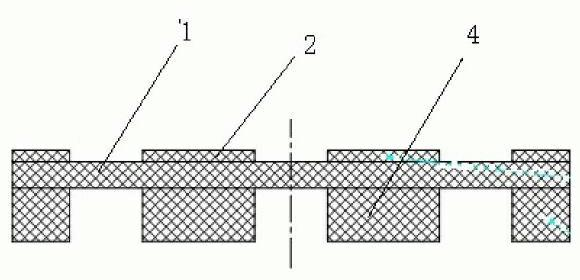

[0010] As shown in the figure: a backing plate for the packing box of automobile rims, characterized in that the upper end of the backing plate 1 is provided with a baffle 2 which separates the backing plate into at least two circles, and the lower end of the backing plate 1 is provided There are at least two rows of triangular brackets 3 longitudinally and horizontally. The backing plate 1, baffle 2 and triangular bracket 3 are made of cardboard with a thickness of 3mm. The technical indicators are: burst resistance: ≥16Kgf / cm, puncture strength: ≥105Kgf· cm, edge pressure strength: ≥7kgf / cm, adhesive strength: ≥6kgf / flute·10cm water absorption: (positive / reverse) ≤35 / 50g / m, delivery moisture: (11+P3)%, when in use , In conjunction with the bottom plate and the upper cover, place 6 car wheels on the backing plate, put the front of the wheel into the circle surrounded by the baffle t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap