Drainage process for suspension in gas purification and absorption process

An absorption process and gas purification technology, applied in chemical/physical processes, chemical methods for reacting gas medium with gas medium, chemical instruments and methods, etc., can solve problems such as hydrogen sulfide escape, pipeline blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

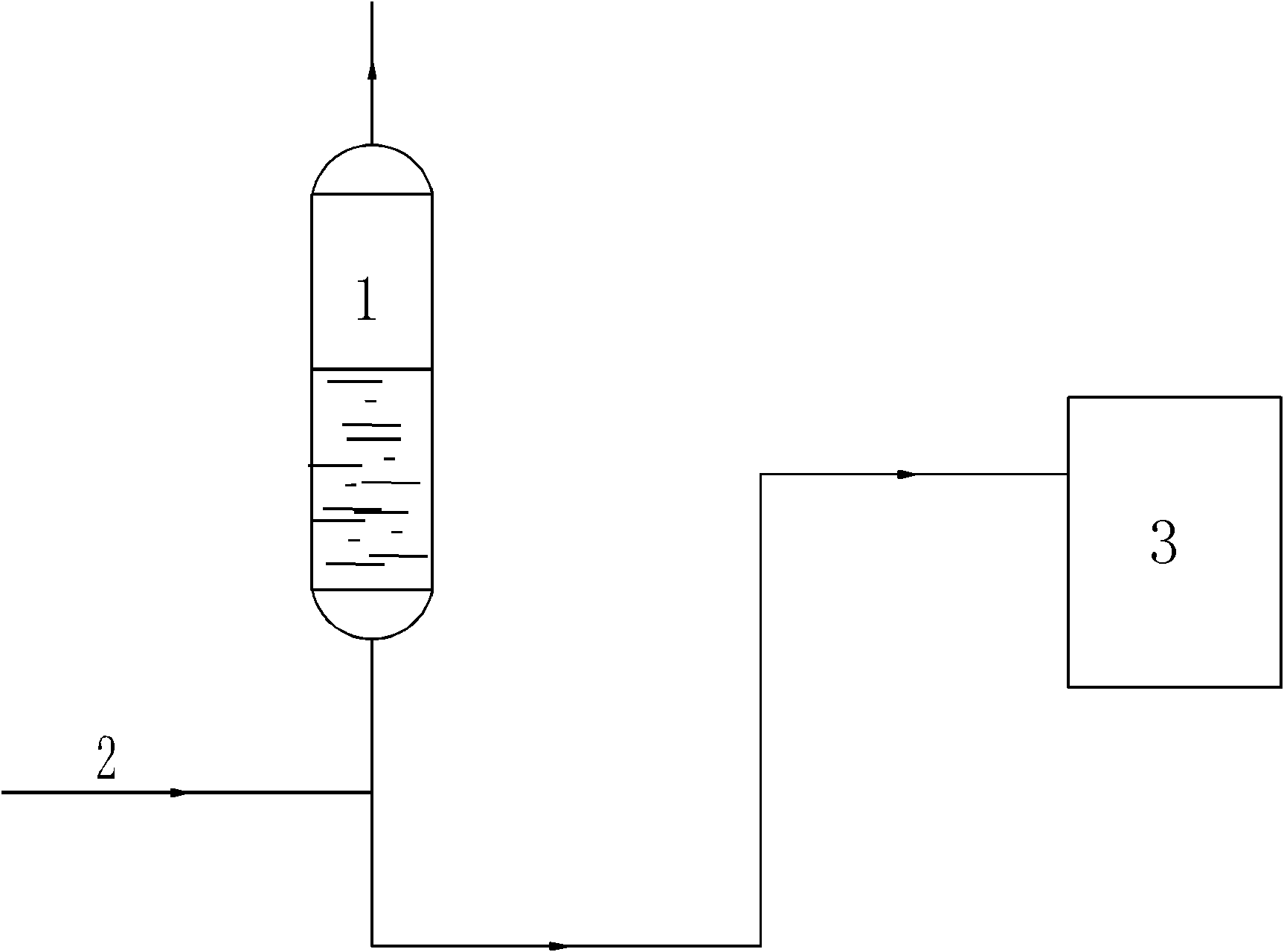

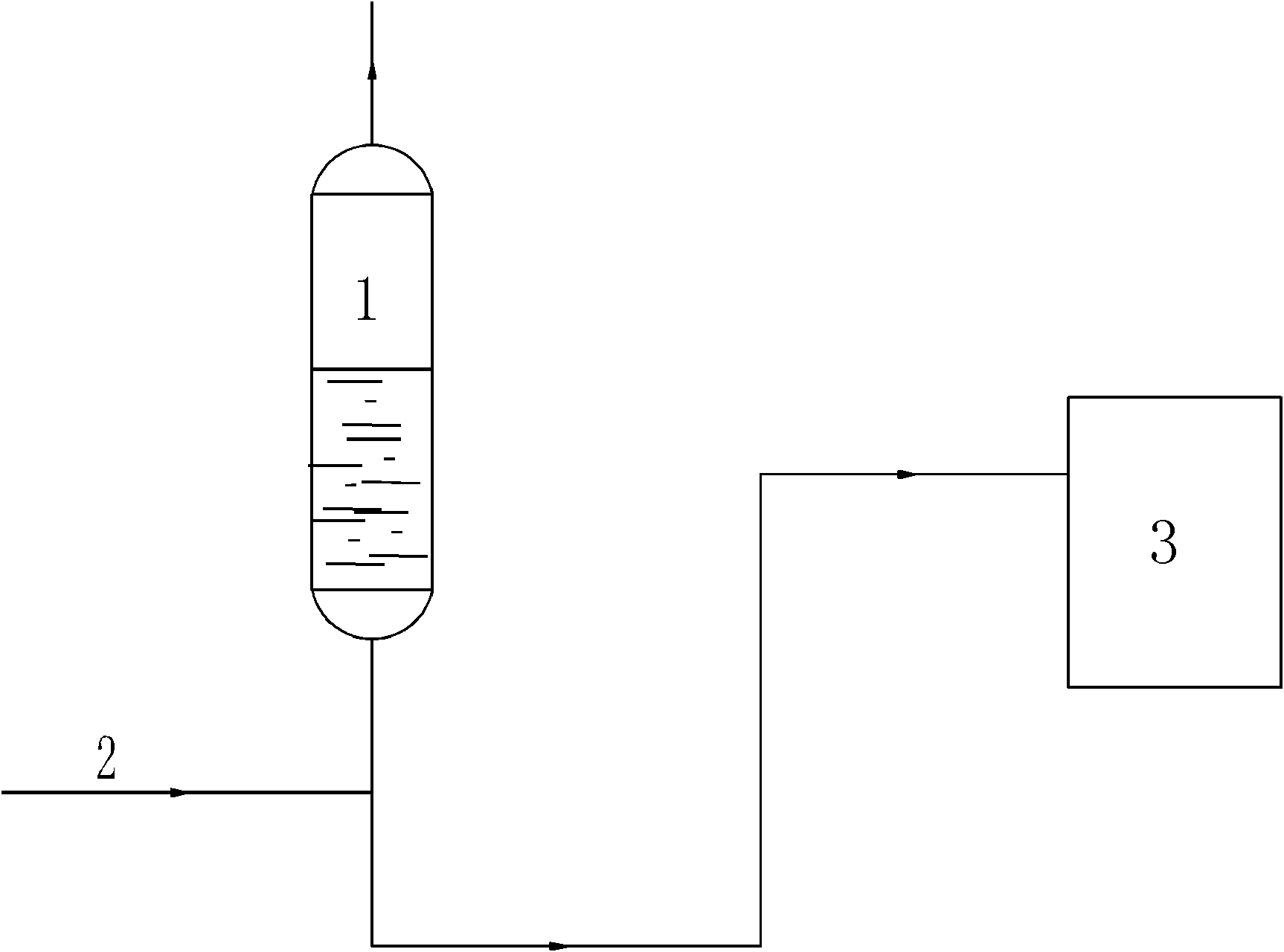

[0011] Barium carbonate drainage process in exhaust gas scrubbing containing hydrogen sulfide and carbon dioxide:

[0012] The exhaust gas containing hydrogen sulfide and carbon dioxide is passed through the tower. After the barium sulfide in the barium sulfide solution in the tower reacts with carbon dioxide to completely turn into barium carbonate, the exhaust gas inlet is closed, and the automatic control valve for filling nitrogen is opened, and the nitrogen accumulated in the tower replaces hydrogen sulfide. After exiting the tower, close the gas phase valve of the tower, continue to fill the tower with nitrogen, and at the same time open the drain valve at the bottom of the tower to start discharging the barium carbonate suspension in the tower to the storage tank. Nitrogen to nitrogen escapes from the end of the drain tube, indicating that the barium carbonate suspension in the drain tube is no longer present, preventing the residual liquid from accumulating in the tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com