Preparation method of macromolecule-supported catalyst for hydrogenation of nitrile-butadiene rubber

A technology for nitrile rubber and hydrogenation catalysis, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., and can solve high-load pretreatment methods, carrier loss, etc. problem, to achieve the effect of simple recovery, reduced hydrogenation cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

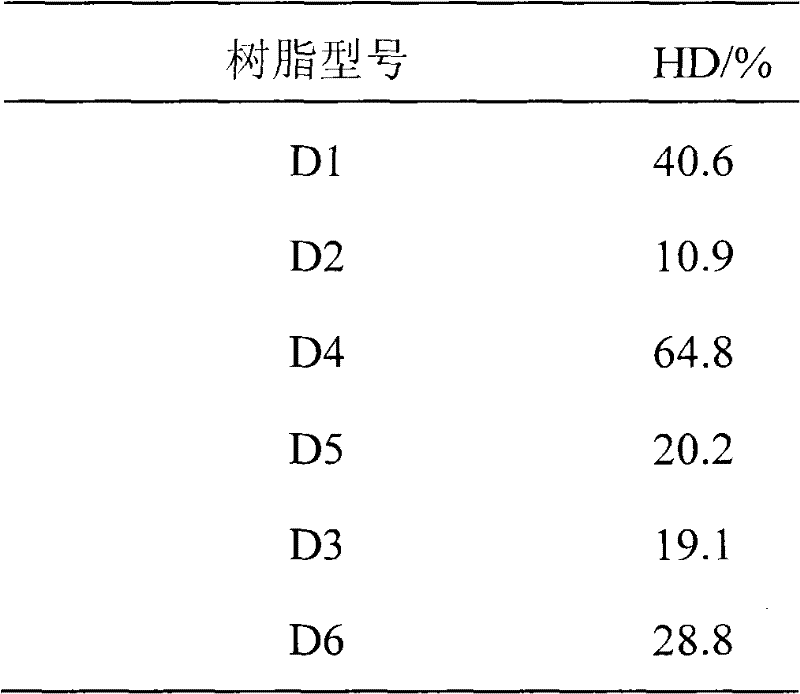

Embodiment 1

[0022] Take 3.0000g NBR and dissolve it in xylene solvent to form NBR glue with a concentration of 1.0%, and add it to the high-pressure reactor. Add 0.0300g RhCl to the reactor 3 , 0.3000g resin D1, controlled temperature 120°C, pressure 3.0MPa, reaction time 8h, cooled, discharged, isopropanol condensed, placed in a vacuum oven for 48h, test the degree of hydrogenation. The results are shown in Table 1

Embodiment 2

[0024] Change resin D1 in embodiment 1 to resin D2, and others are the same as embodiment 1. The results are shown in Table 1

Embodiment 3

[0026] Change resin D1 in embodiment 1 to resin D3, and others are the same as embodiment 1. The results are shown in Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com