Cooling device for vertical bright annealing furnace

A technology of cooling device and annealing furnace, which is applied in the direction of furnace, heat treatment furnace, furnace type, etc., can solve the problem of destroying the surface finish, and achieve the effect of high finish and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

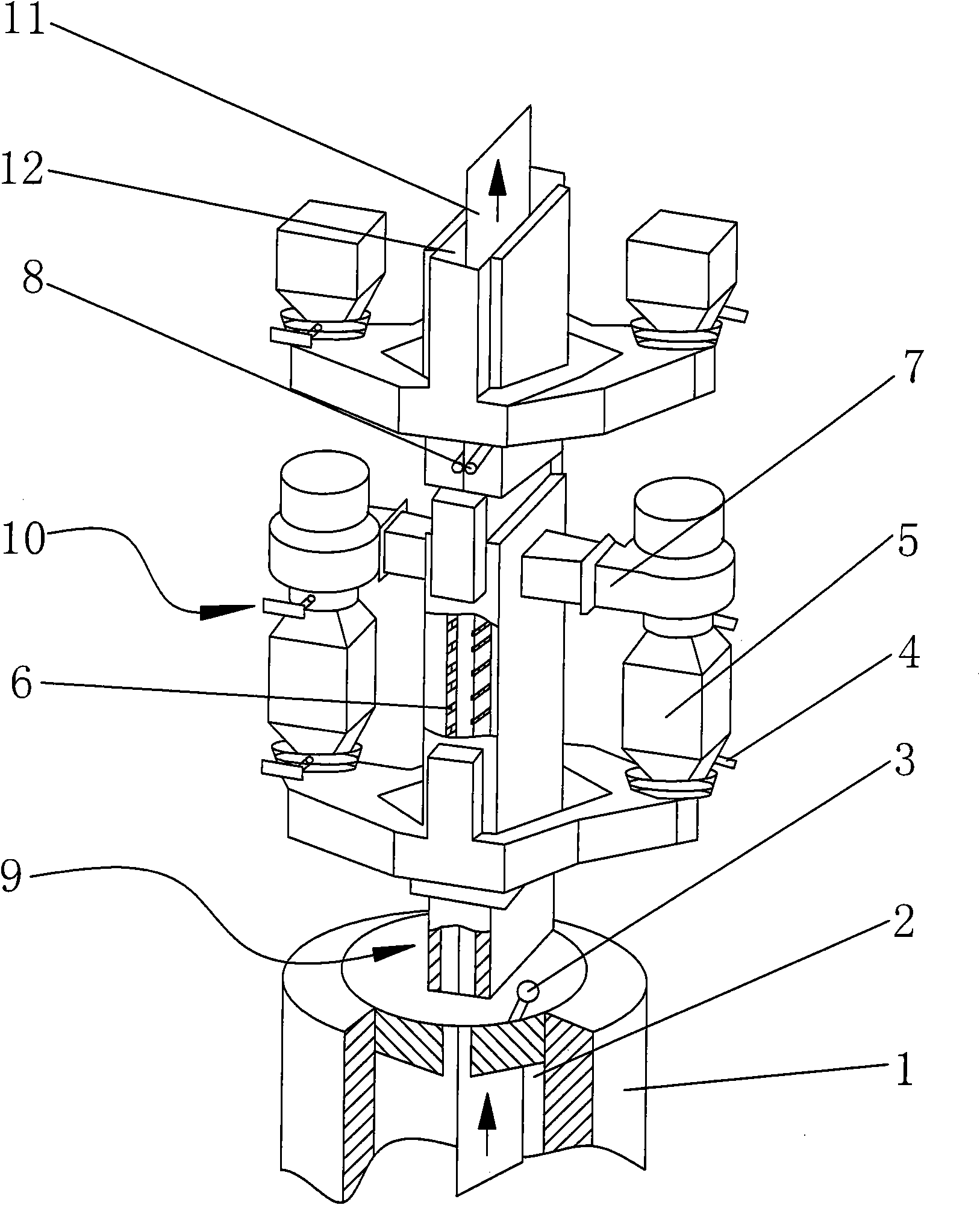

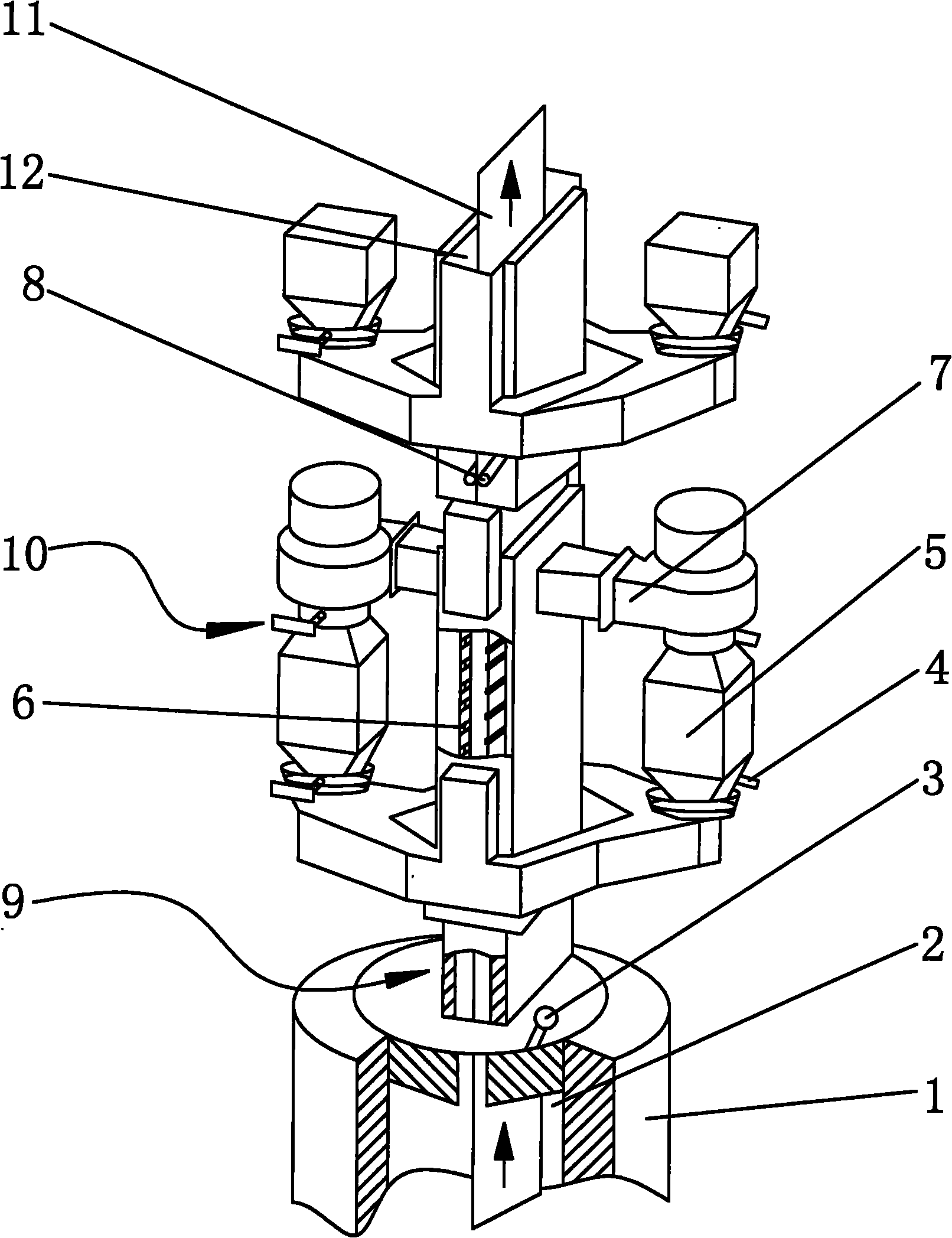

[0017] The concrete structure of the present invention will be described in detail below with reference to accompanying drawing:

[0018] Refer to attached figure 1 As shown, a cooling device for a vertical annealing furnace includes: a radiant cooling zone 9 and several sections of cooling injectors 10 connected to the radiative cooling zone 9 . Radiant cooling zone 9 is a natural cooling zone, which is the transition from the annealing furnace in the heating section to the main cooling zone in the cooling section, and is generally set to be about 1 meter long.

[0019] The cooling injector 10 includes a cooling channel 12 , a heat exchanger 5 and a spray fan 7 symmetrically arranged on both sides of the cooling channel 12 . The spray cooler 10 can be provided with multi-stage cooling, and the specific number of stages can be adjusted according to the size of the furnace. The cooling injector 10 of the present embodiment is provided with two stages. The lower end of the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com