Sling replacement method for suspension bridge

A technology for suspension bridges and slings, applied in the field of replacement of slings for suspension bridges, can solve problems such as the lack of mature cable replacement methods, and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

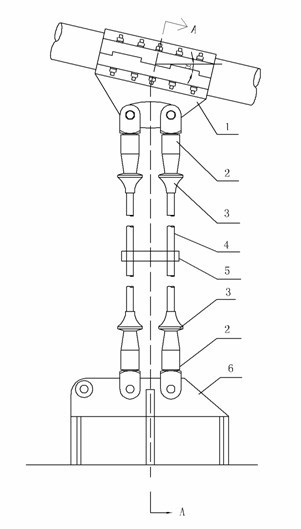

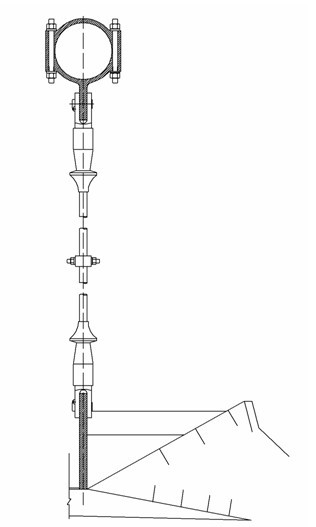

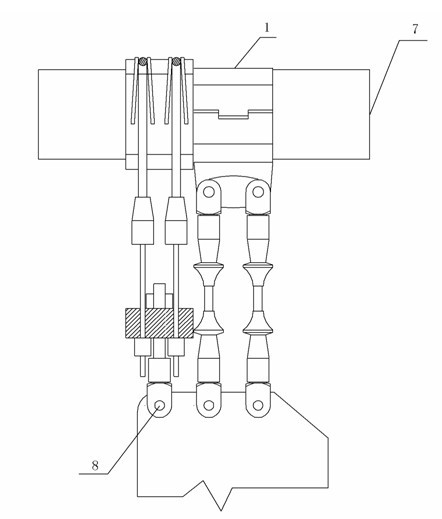

[0026] see image 3 and Figure 4 , image 3 It is a schematic diagram of the implementation process of the present invention. Figure 4 It is a schematic diagram of the temporary cable clip involved in the present invention. The suspension bridge suspension cable that the present invention relates to changes cable method, and described method comprises following process:

[0027] 1) Install a temporary cable clamp 9 on the main cable 7 of the suspension bridge, and pad the rubber plate inside the temporary cable clamp to prevent the temporary cable clamp from damaging the protective layer of the main cable.

[0028] 2) Two auxiliary cables 10 are erected on the temporary cable clamp, and the middle of the two auxiliary cables bypasses the groove of the temporary cable clamp, and four small pull rods 11 are connected at both ends, and the auxiliary cables are temporarily fixed with fasteners to prevent slippage.

[0029] 3) Install the tie rod 15 on the hoisting hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com