Adaptive control method for excavator

An adaptive control and excavator technology, applied in the field of control, can solve the problems of increasing the work complexity of the excavator operator, unfavorable full adaptation of the excavator, etc., and achieve the effect of low fuel consumption and comfortable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

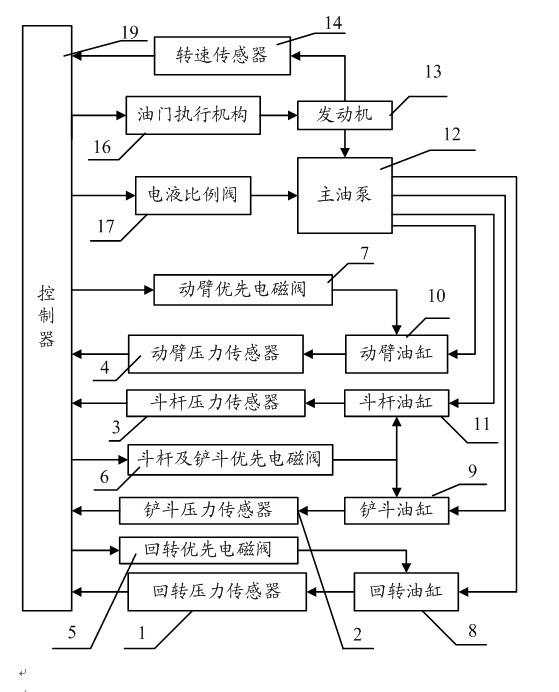

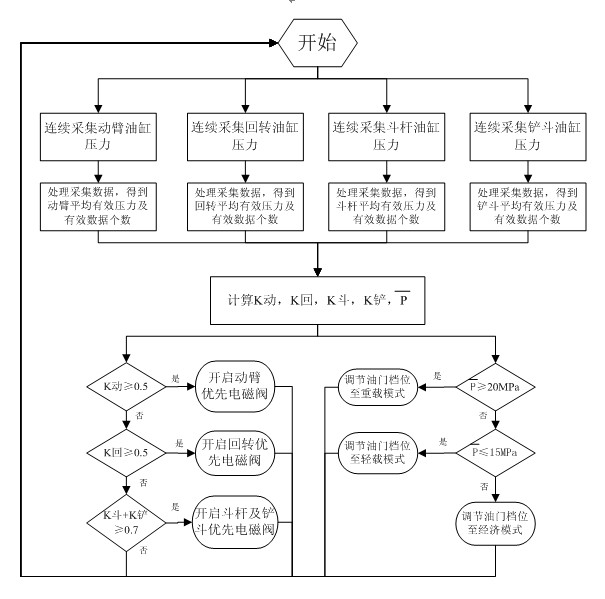

[0044] see figure 1 and figure 2 , the excavator adaptive control method, proceed as follows:

[0045] A. Install an adaptive control system on the excavator:

[0046] The adaptive control system includes a controller 19, a speed sensor 14, a boom pressure sensor 4, a stick pressure sensor 3, a bucket pressure sensor 2, a swing pressure sensor 1, a boom priority solenoid valve 7, and a swing priority solenoid valve 5 , stick and bucket priority solenoid valve 6, wherein the boom pressure sensor 4 is mounted on the excavator arm cylinder 10, the stick pressure sensor 3 is mounted on the excavator stick cylinder 11, and the bucket pressure sensor 2 is mounted on the On the bucket oil cylinder 9 of the excavator, the rotary pressure sensor 1 is installed on the rotary oil cylinder 8 of the excavator;

[0047] B. Perform parameter collection:

[0048] B1. Boom pressure sensor 4 collects boom pressure , to get the average effective pressure of the boom : In unit time, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com