Method for sticking cakes in plastering engineering by using laser

A laser, pasting technology, applied in measuring devices, instruments, measuring instruments, etc., can solve the problem of not meeting the requirements of high-efficiency and high-quality building plastering construction, uncontrollable room size consistency, unable to choose the best plastering thickness, etc. problems, to achieve the effect of reducing arbitrariness, high construction efficiency, and reducing the amount of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

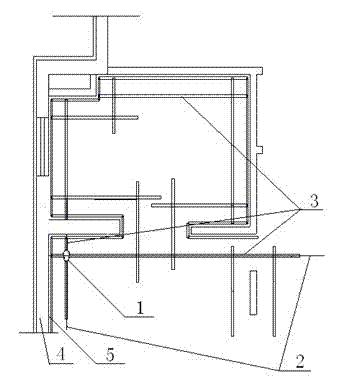

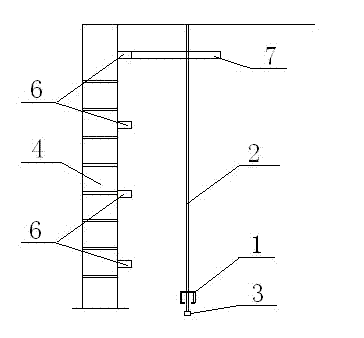

[0013] Embodiment of the present invention: when carrying out the cake sticking construction of plastering project, adopt the method for sticking cake of laser in a kind of plastering project of the present invention to carry out construction, promptly when carrying out the cake sticking construction of plastering project, adopt laser The cross-shaped vertical laser surface 2 output by the marking instrument 1 is used as the reference plane for pasting the ash cake 6 to paste the cake, that is, the control line 3 is set in the traditional way on the floor of the house that needs to be plastered, and then the The laser line marking device 1 is placed on the control line 3, and the laser line marking device 1 is adjusted and leveled so that the output cross-shaped vertical laser surface 2 is projected on the ceiling or the floor as two vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com