Air intake apparatus for internal combustion engine

A technology for air intake devices and internal combustion engines, applied to internal combustion piston engines, combustion engines, combustion air/combustion-air treatment, etc., can solve the problems of increasing, hindering the output of internal combustion engines, reducing the mixing ratio of air filling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

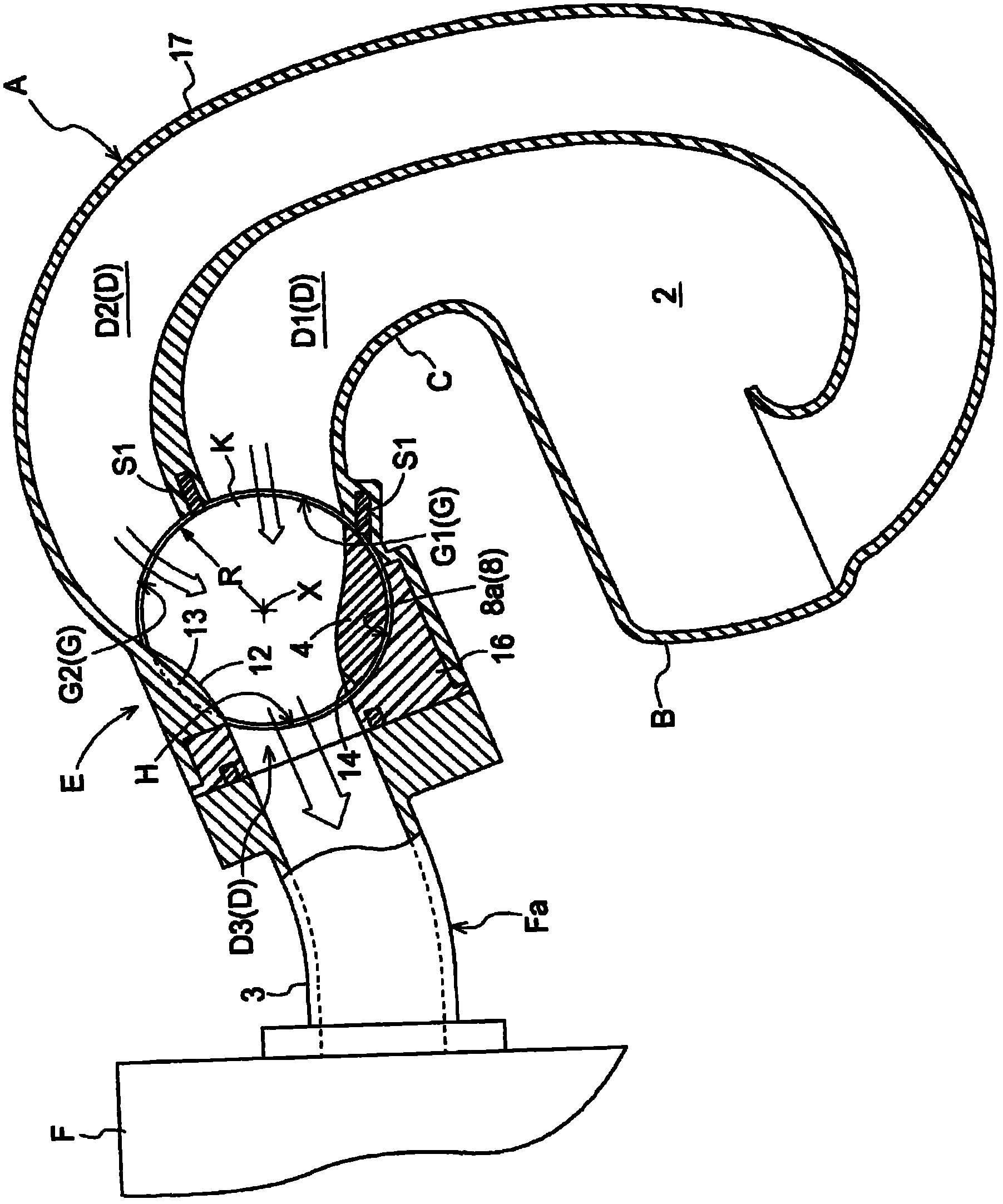

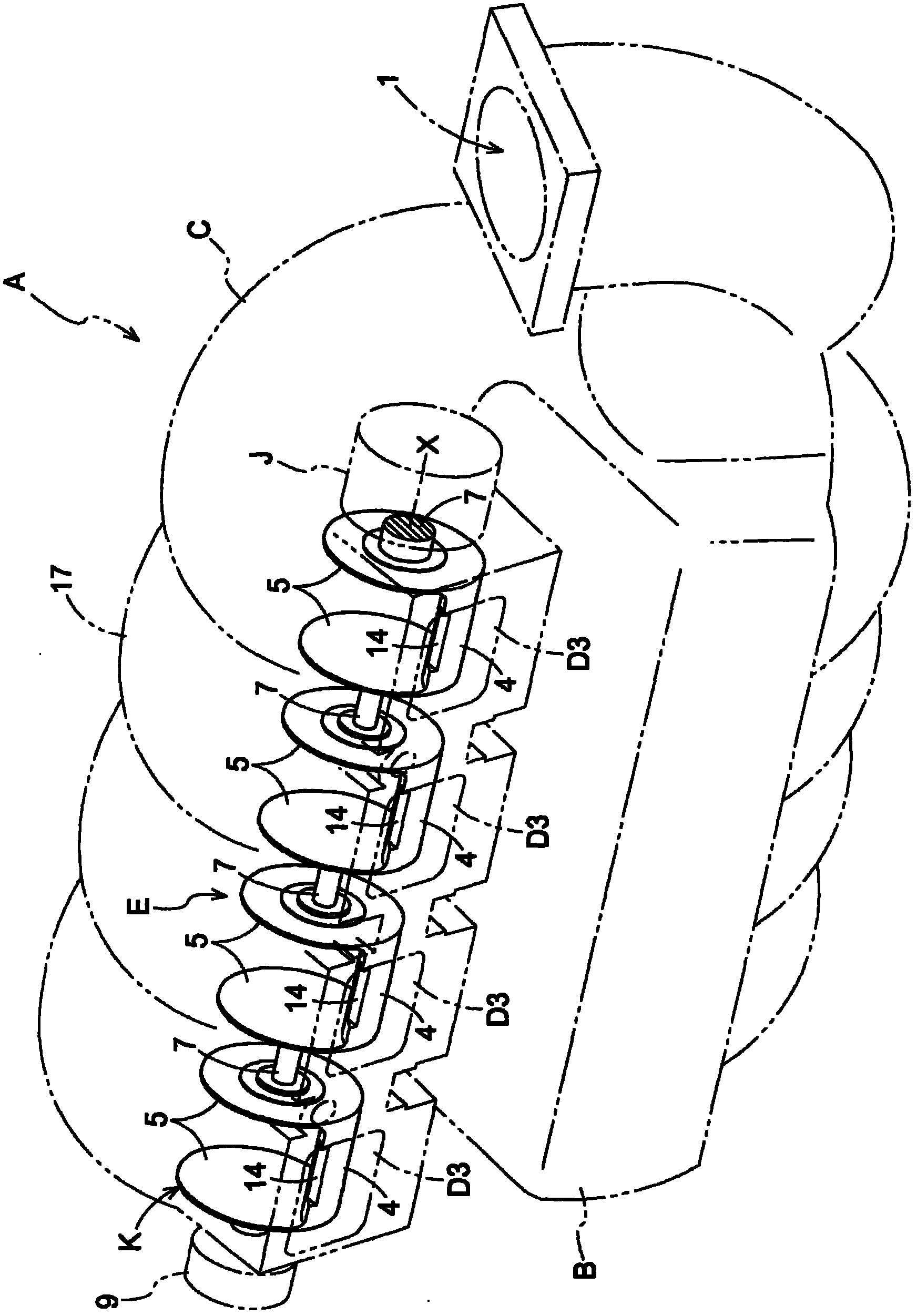

[0035] Next, a first embodiment will be described. Such as Figure 1 to Figure 3 As shown, an air intake device for an internal combustion engine (hereinafter simply referred to as an air intake device) A includes a buffer tank B, a housing C, and a rotary valve E. The buffer tank B includes an inlet 1 and an air storage cavity 2 . The housing C having a hollow shape includes an air inlet D, an air inlet G, and an air outlet H. As shown in FIG. The rotary valve E is installed at the housing C.

[0036] The buffer tank B and the case C are integrally formed by joining resin molded products. The throttle valve is connected to the inlet 1 of the buffer tank B, so that the outside air whose air flow is adjusted by the throttle valve is sucked into the air storage cavity 2 through the inlet 1 .

[0037] The intake port D is connected to the intake portion Fa of each of the four cylinders of the engine F (as an internal combustion engine). That is, according to the present embo...

no. 2 example

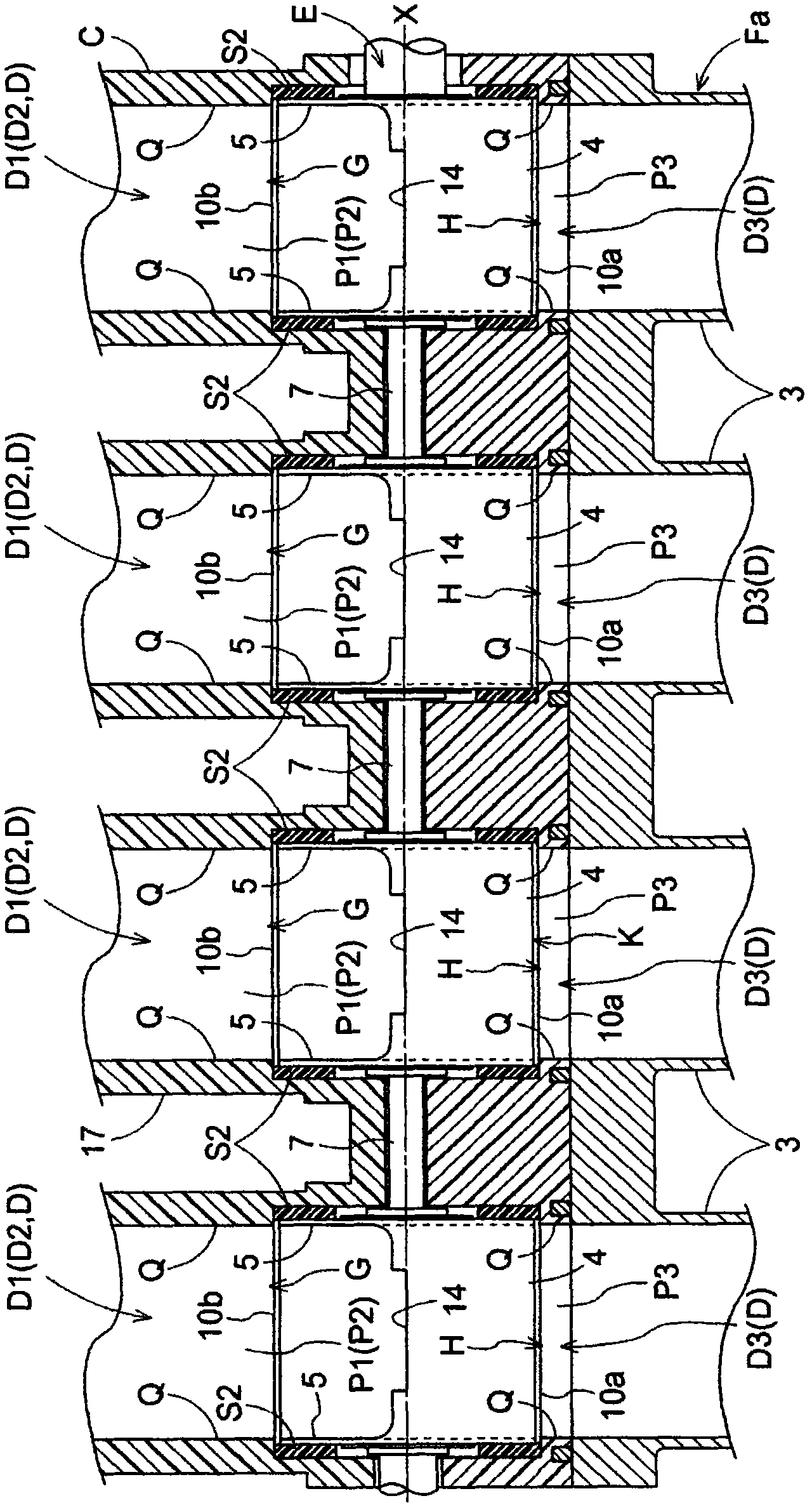

[0062] Below, refer to Figure 12A with Figure 12B A second embodiment will be described. In the second embodiment, the case C is constituted by a body portion 17 and a cover member 16 provided with each air outlet H. As shown in FIG. An insertion port 15 is formed at the body portion 17 , and the rotary valve E is inserted into the insertion port 15 in a direction perpendicular to the rotation axis X and mounted. According to the second embodiment, each inner surface forming portion 13 is provided at the cover member 16 instead of the body portion 17 so that the inner peripheral surface 12 is formed.

[0063] Accordingly, if Figure 12A As shown, in the case of installing the rotary valve E to the main body 17 , the rotary valve E is inserted into the insertion port 15 in a direction perpendicular to the rotation axis X, and installed inside the main body 17 . Then, if Figure 12B As shown, when the insertion opening 15 is covered with the cover member 16, each inner su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com