Method for continuously processing wheel-track force of track vehicle by means of ground test

A technology for ground testing and railway vehicles, applied in neural learning methods, measuring devices, force/torque/work measuring instruments, etc. problem, to achieve the effect of easy promotion, simple operation, and increasing the number of patches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with example the present invention is described in further detail.

[0022] 1. A continuous processing method for ground testing railway vehicle wheel-rail force, the steps of which are:

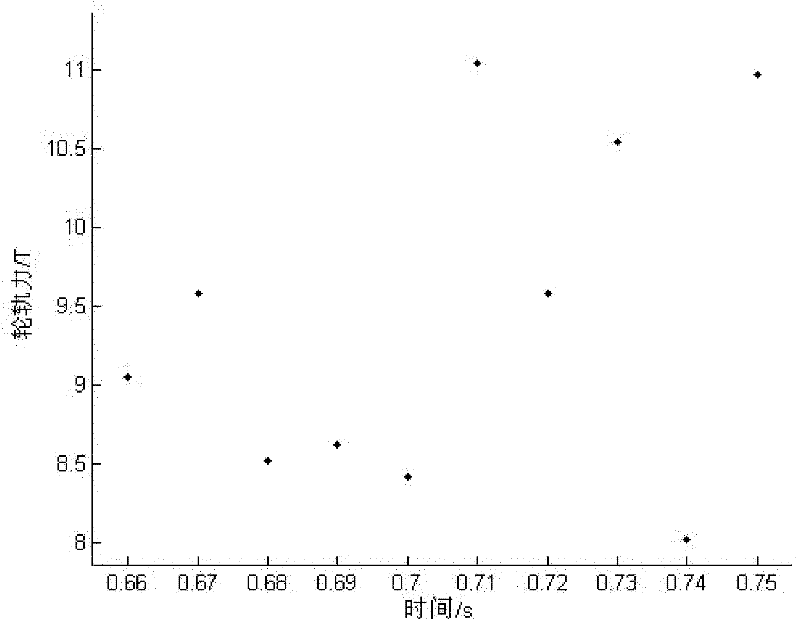

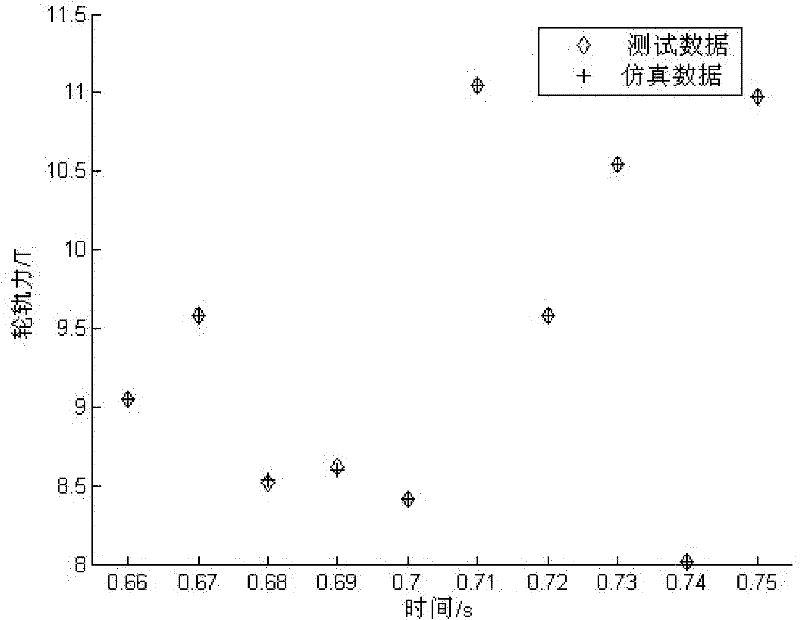

[0023] A. Through the track ground test, the wheel-rail force test data and corresponding time data of the wheel set passing through the track test area are obtained, and the data smaller than the threshold value are removed to form separate waveform data, and then the maximum value of each waveform data is taken out. Get discrete wheel-rail force data and its time data.

[0024] When the present invention is implemented, the threshold value only needs to satisfy the condition that it is greater than the maximum value of the noise in the wheel-rail force test data and less than the minimum value of the wheel-rail force during the track ground test, and the usual value is 0.9-2 tons.

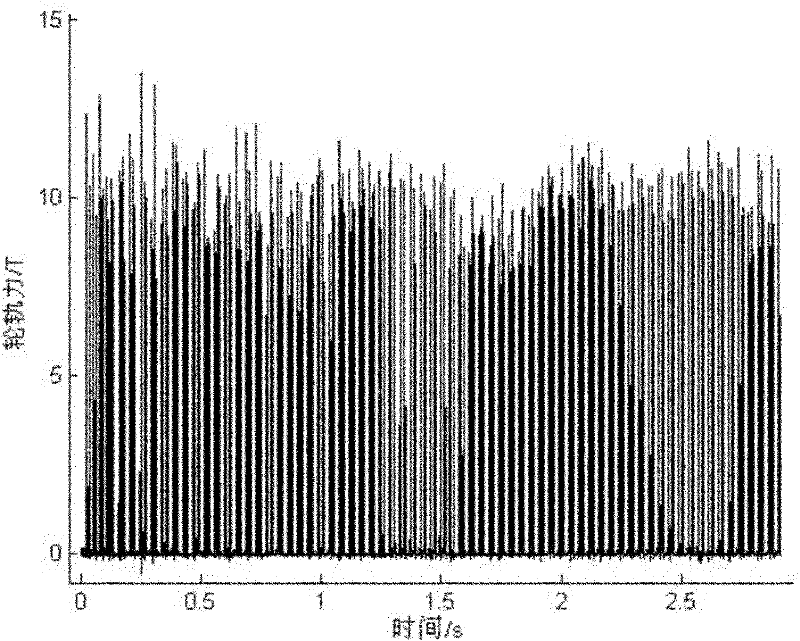

[0025] The wheel-rail force test data when a certain wheel set passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com