End wall of a pulp dryer, pulp dryer, and method for observing the inner parts of a pulp dryer

A dryer and end wall technology, applied in the direction of the dryer section, pulp dehydration, wing fan arrangement, etc., to achieve the effects of reducing heat loss, reducing heat loss, and improving drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

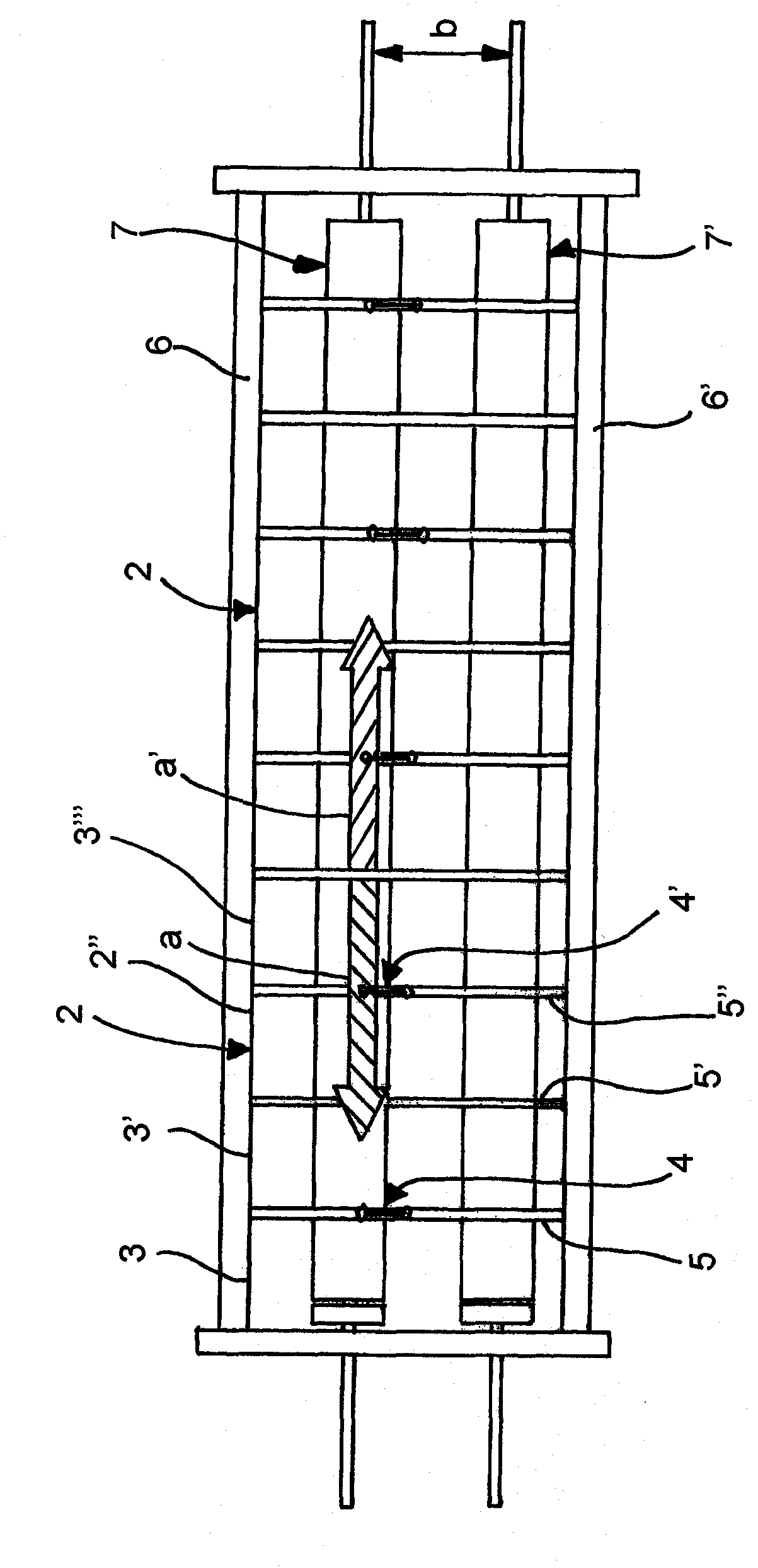

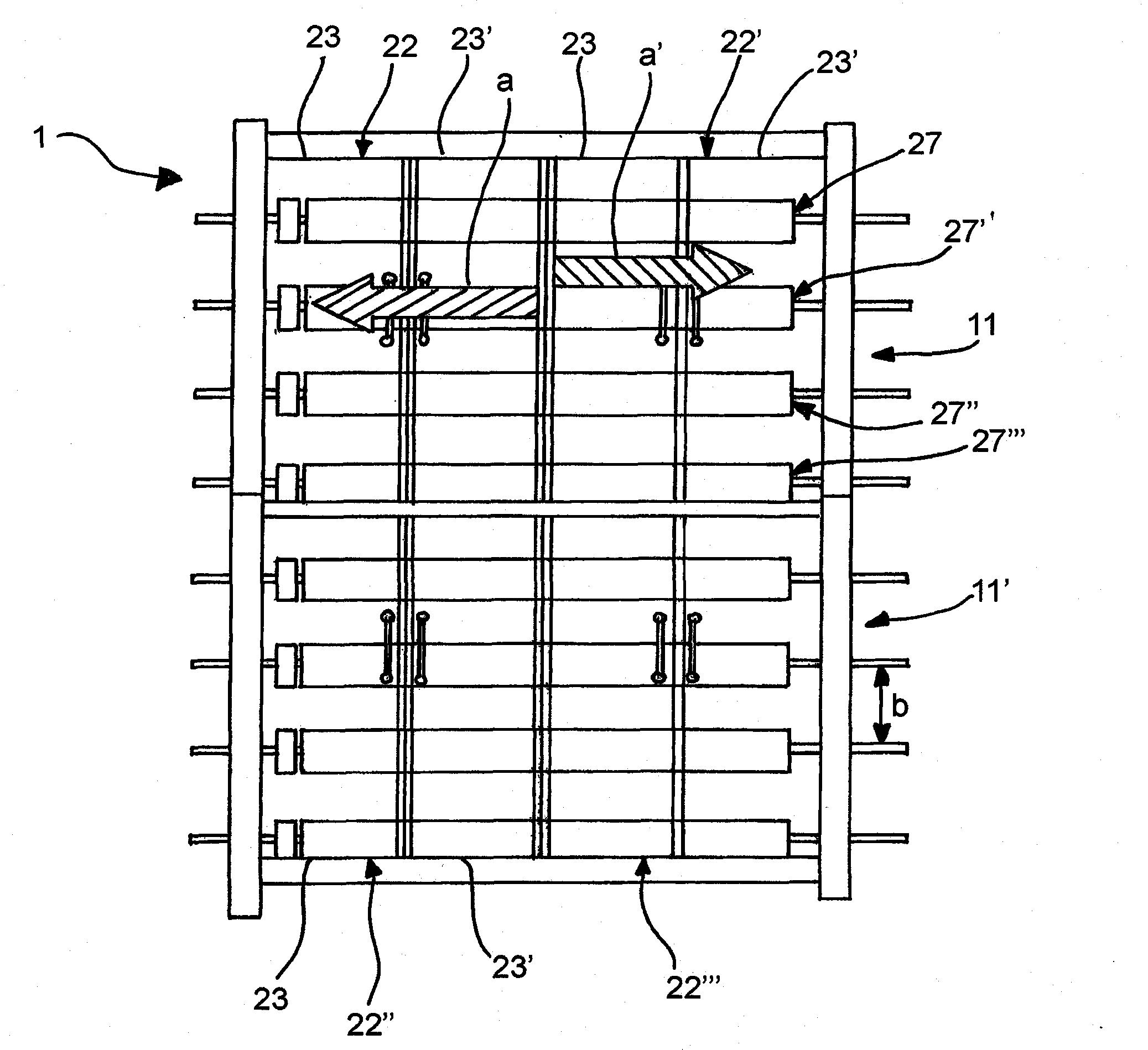

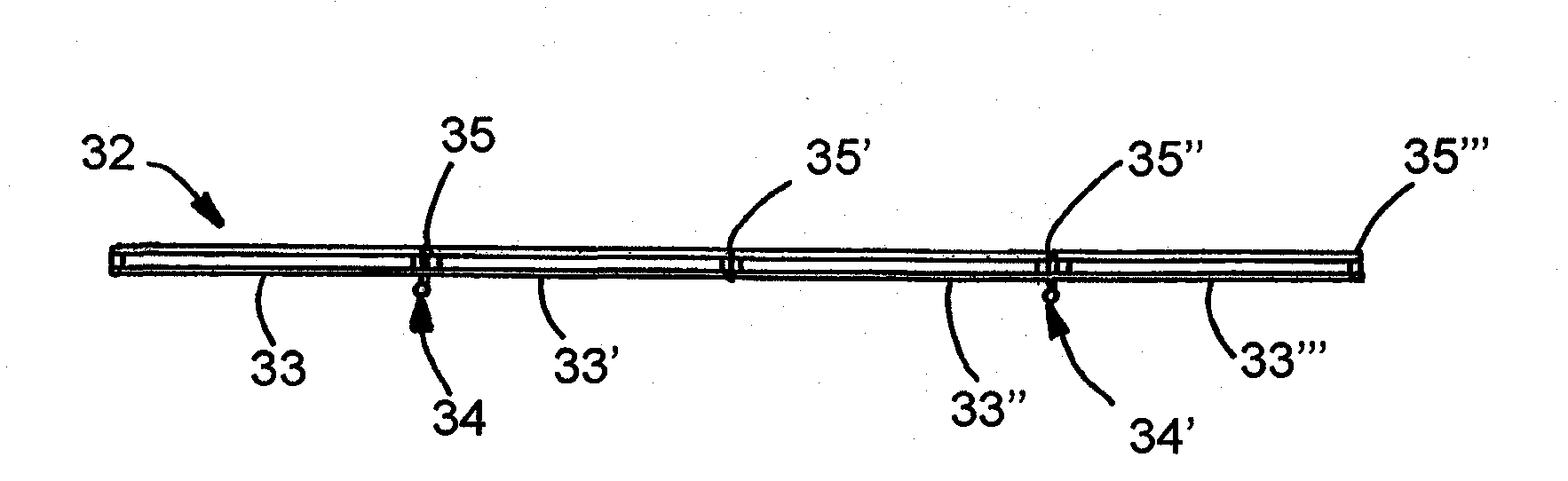

[0064] figure 1 A part of the end wall of a pulp dryer according to an embodiment of the present invention is shown. The figure shows two end wall members 2, 2', of which the first end wall member 2 can be arranged at a position open towards the operating side of the pulp dryer, and the second end wall member 2'can be arranged towards the pulp web. The position where the drive side of the dryer is open. The opening direction of the end wall members 2, 2’ is in figure 1 Indicated by arrows a, a'. The end wall member 2 includes four partial members 3, 3', 3", 3"', and the partial members 3, 3', 3", 3"' are arranged to open to the operating side in a folding door manner. The two partial members 3, 3'are provided with moving devices 4, 4'such as gripping handles, which can be used to move the partial members from the closed position to the open position. The second end wall member 2'includes six partial members respectively opened in a folding door manner. The respective partial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com