Composite material for thermal insulation and sound insulation and method for the manufacture thereof as well as household appliance

A technology of composite materials and household appliances, which can be applied to other household appliances, household components, household appliances, etc., can solve the problems of sound insulation and heat insulation effects not being optimal, and achieve high thermal insulation and thermal conductivity, good isolation characteristics, high The effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

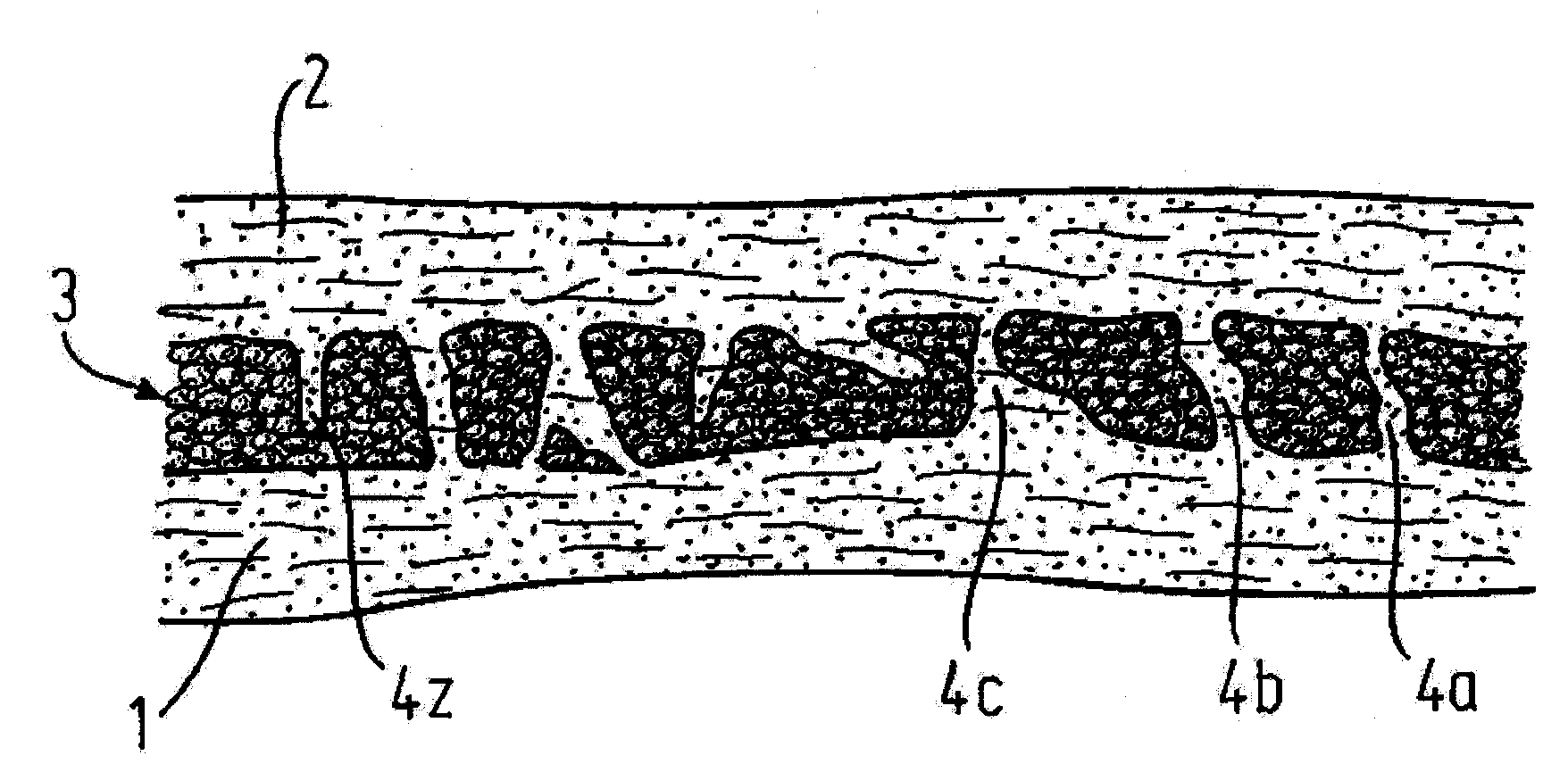

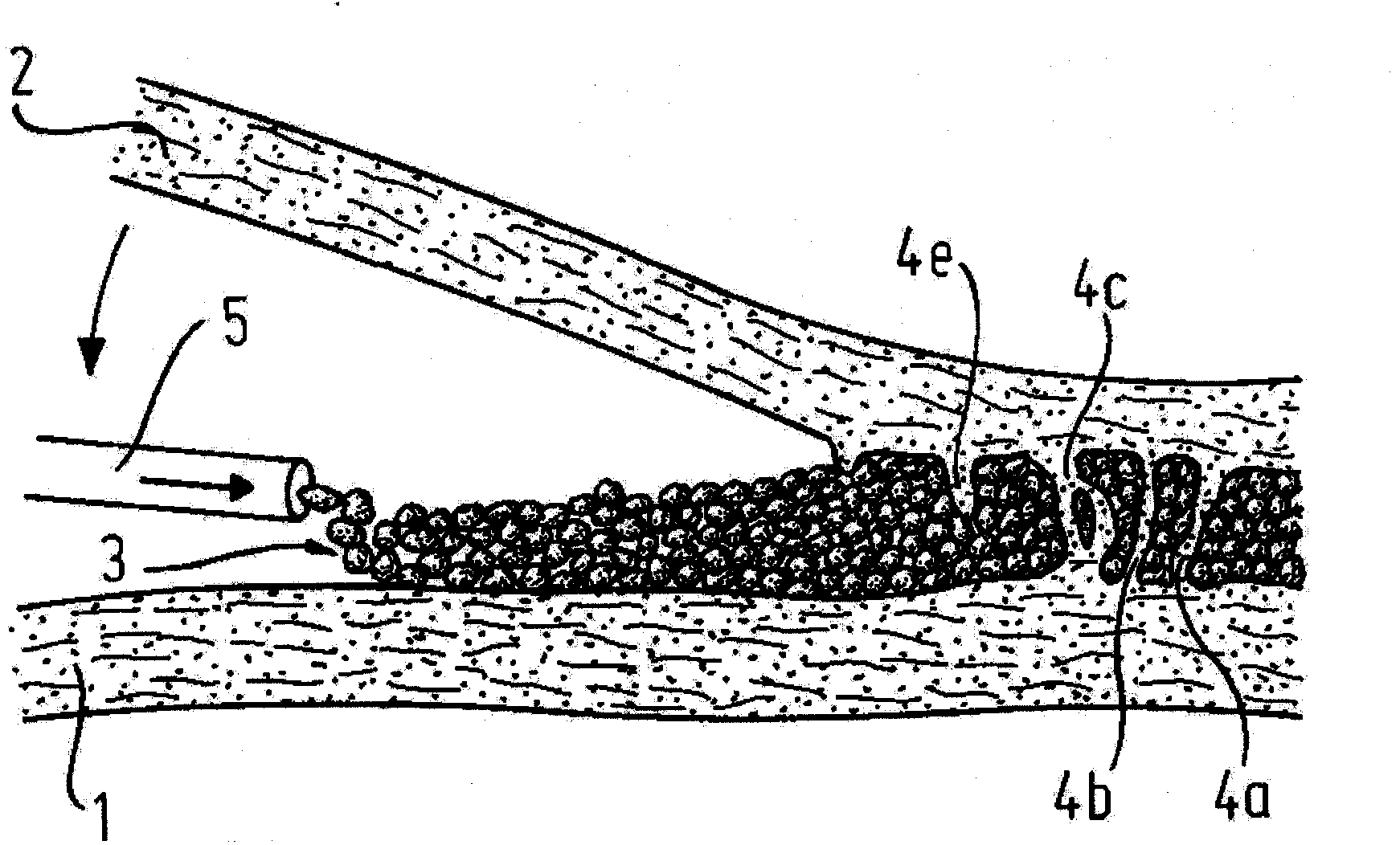

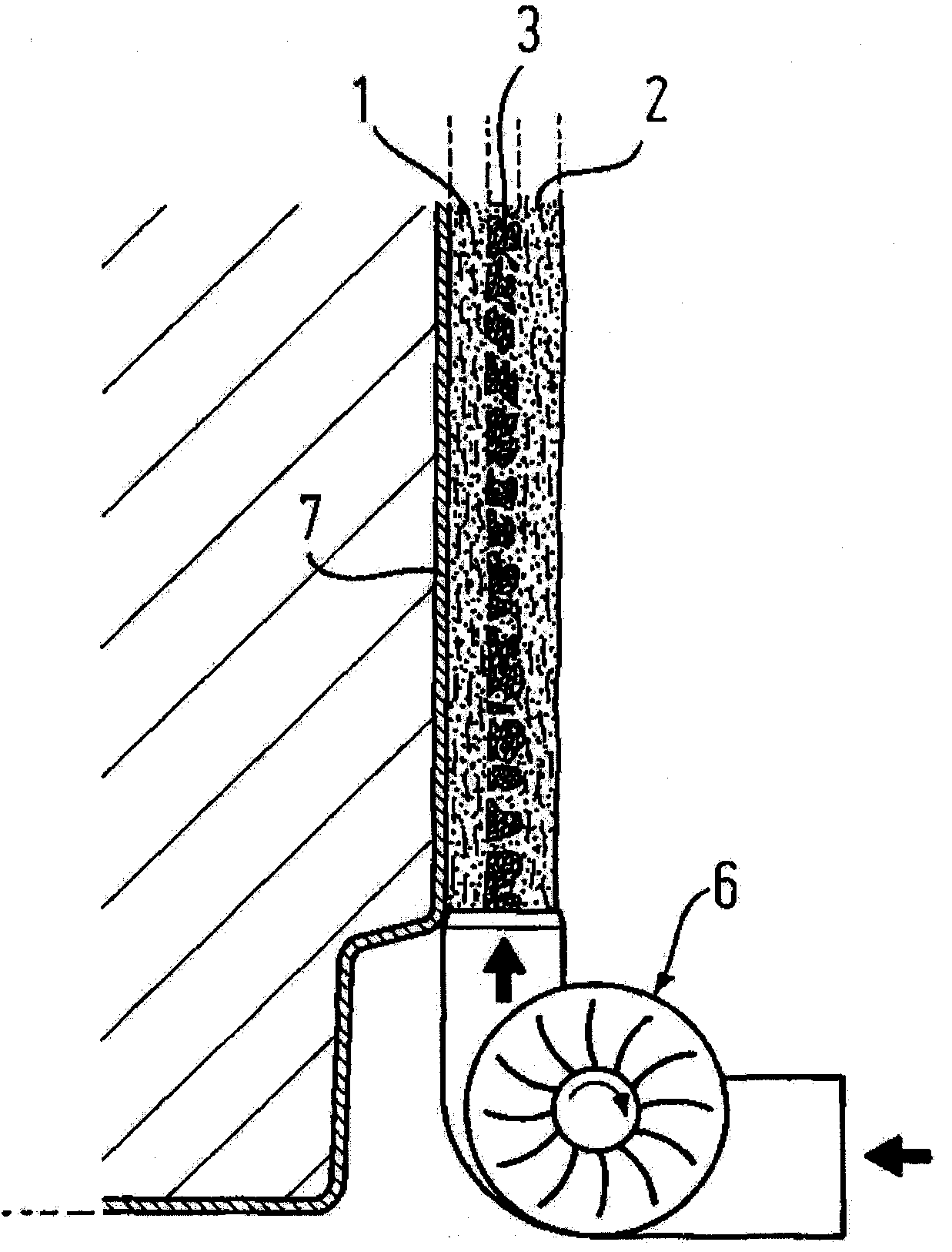

[0023] figure 1 A section through a composite material according to the invention with a lower layer 1 , an intermediate layer 3 and an upper layer 2 is shown. The two outer layers 1 and 2 consist of a bituminous material which can be enriched with stone fines in a targeted manner. The advantage of the stone powder mixture is the increased sound insulation, since the stone powder has a better absorption potential than pure bitumen due to its specific density.

[0024] However, the stone powder mixing does not have to take place in the two outer asphalt layers, but can be present in only one of the two layers 1 or 2. However, it is expedient that when producing the composite material according to the invention, the outer asphalt layer does not accumulate stone dust and does not accumulate stone dust on the same scale as the lower layer, because for the construction of the connecting channels 4a to 4z the bitumen needs a certain viscosity and the stone powder Viscosity can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com