Microcapsule suspension concentrate for preventing and removing rice paddy weed and preparation method thereof

A water suspension and microcapsule technology, which is applied in the direction of herbicides and algicides, botanical equipment and methods, chemicals for biological control, etc., can solve the problems of high cost of weeding and incomplete weeding, and achieve the dosage form Stable and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of the capsule skin: add 50 grams of urea and 120 grams of 37% formaldehyde aqueous solution to 500ml, adjust the pH value to 8.0 with sodium hydroxide under stirring, react at 65 degrees for 1.5h to obtain the urea-aldehyde resin prepolymer (as capsule skin material spare).

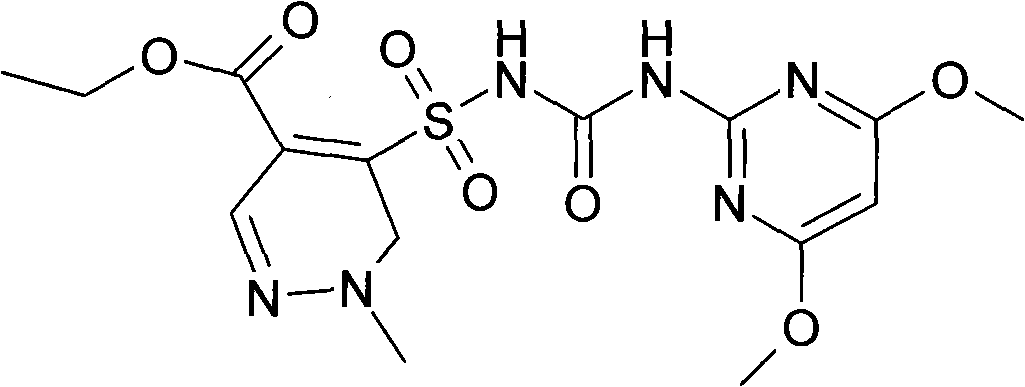

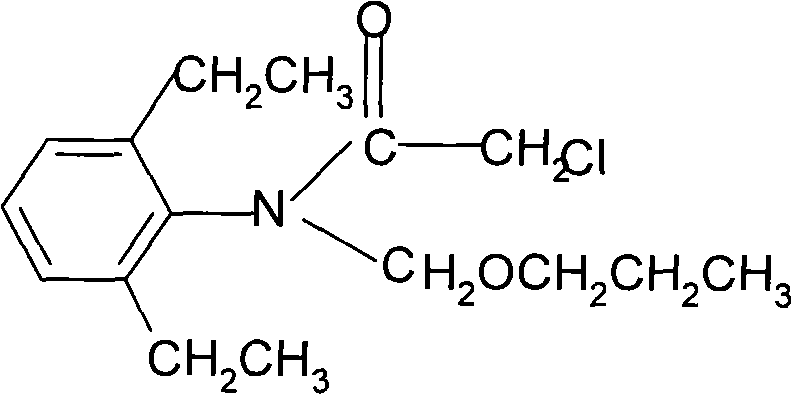

[0024] Preparation of microcapsule suspension: In a 1000ml three-necked bottle, add 50 grams of pretilachlor, 3.0 grams of pyrazosulfuron-methyl, and 48.5 grams of methyl isobutyl ketone, heat in a water bath, stir until transparent, add 25 grams of uric aldehyde Resin prepolymer aqueous solution, then add 2 grams of calcium dodecylbenzenesulfonate, 2.2 grams of nonylphenol polyoxyethylene ether, 0.4 grams of sodium lauryl sulfate, and control the speed at 1500r / min and stir for 30 minutes to form a stable water emulsion; then reduce the rotation speed to 700r / min, adjust the pH value to 2.0 with 5% dilute hydrochloric acid, and carry out polycondensation into capsules; gradually i...

Embodiment 2

[0025] Example 2 In a 30-liter three-necked bottle, add 5 kg of pretilachlor, 300 g of pyrazosulfuron-methyl, 4.8 kg of toluene, start stirring, heat in a water bath, stir until transparent, add 2.5 kg of urea-aldehyde resin prepolymer aqueous solution, Then add 200 grams of calcium dodecylbenzenesulfonate, 220 grams of nonylphenol polyoxyethylene ether, 40 grams of sodium lauryl sulfate, and control the speed at 1200r / min and stir for 30 minutes to form a stable water emulsion; then reduce the speed To 500r / min, use 5% dilute hydrochloric acid to adjust the pH value to 2.0, and carry out polycondensation to form capsules; gradually increase the temperature at about 55 degrees to solidify the capsule skin, and the reaction is completed in about 2 hours, and adjust the pH value to 7.0 with 20% sodium hydroxide solution , finally add 300 grams of polyvinyl alcohol in an appropriate amount of thickener, add antifreeze agent to make up water to 20 kilograms, and stir to obtain 26.5...

Embodiment 3

[0026] Example 3 Start stirring, put 200 kg of pretilachlor, 12 kg of pyrazosulfuron-methyl, and 190 kg of methyl isobutyl ketone into a 1500-liter shearing kettle in sequence, open the steam valve, and control the temperature in the kettle between 35-45 degrees. In between, stir for about 30 minutes, sample the appearance, and start to drop 200 kg of pre-measured urea-aldehyde resin prepolymer with a solid content of 50% after passing the test. After about 20 minutes, add 4 kg of dodecylbenzenesulfonate Calcium acid calcium, 8.8 kilograms of nonylphenol polyoxyethylene ether, 2 kilograms of sodium lauryl sulfate, speed up the stirring speed, control the rotating speed at about 1300 rpm, and keep it for about 10 minutes; then adjust the stirring speed to about 500 rpm, and use 5% dilute hydrochloric acid to adjust the pH value to 2.0, heat up to 55-60 degrees, and continue to react for three hours; then use liquid caustic soda to adjust the pH value to neutral, and finally add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com