High efficiency air filter

A high-efficiency air and filter technology, used in suction filters, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of affecting the suction power of the machine, ejecting dust and falling to the ground, and inconvenient for customers to use, to increase dust storage. Space, reduce the suction rate and reduce the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

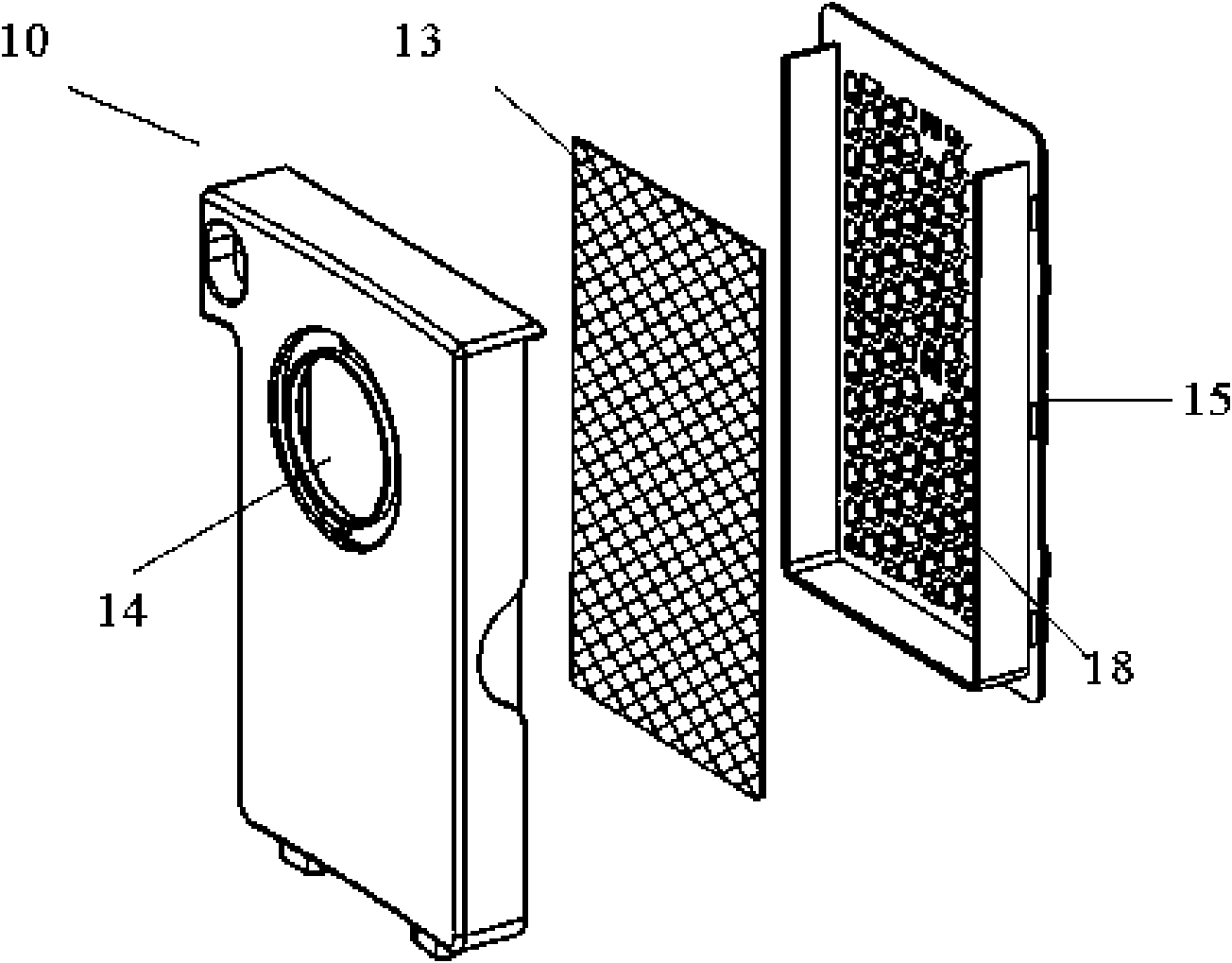

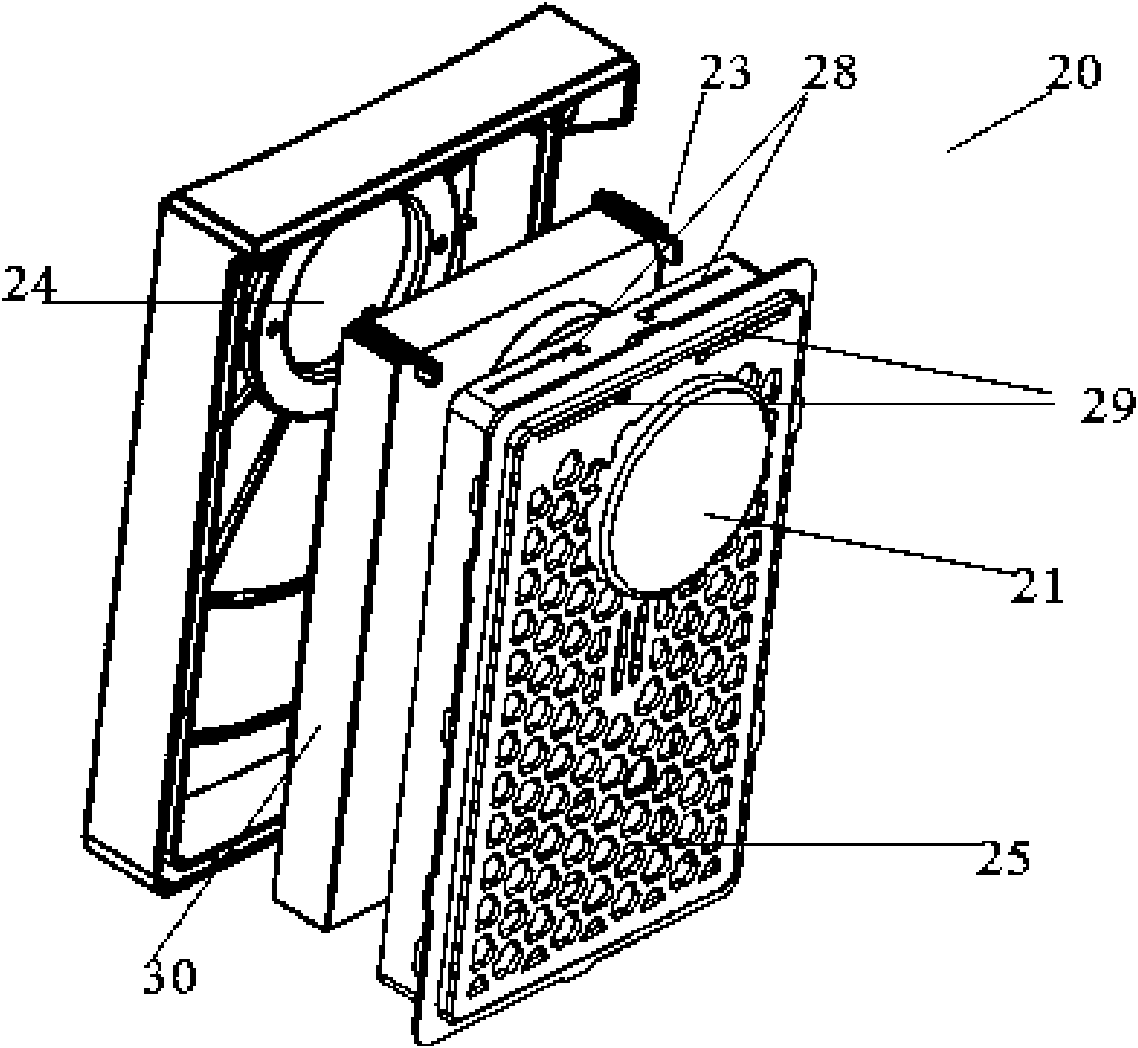

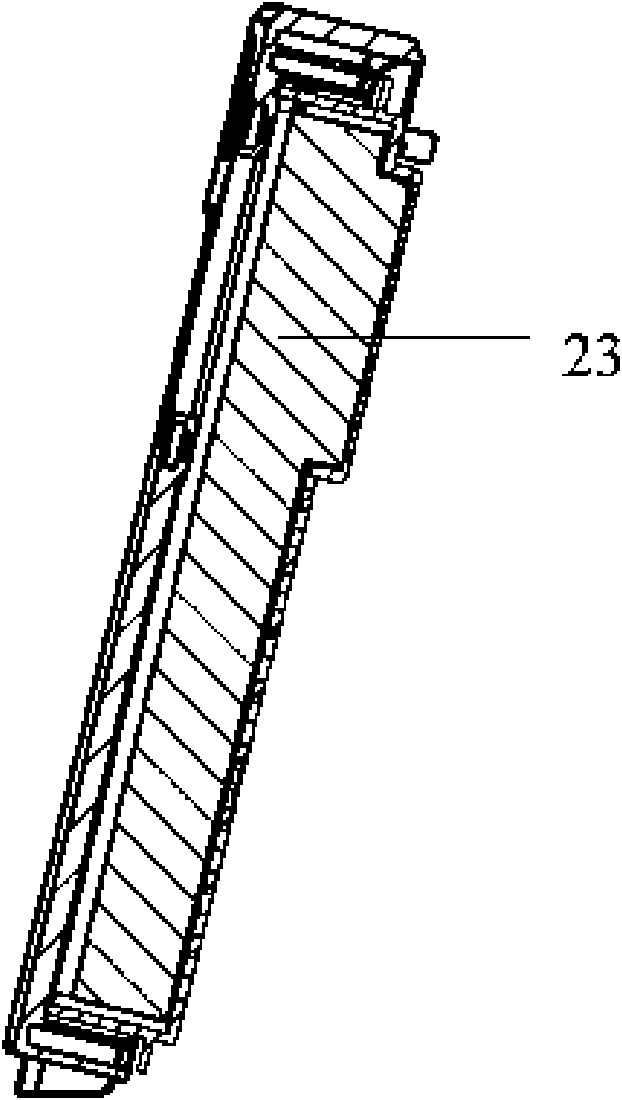

[0028] Such as Figure 2-6 As shown, the high-efficiency air filter 20 of the present invention is a box structure, and the box body is divided into two parts: a front cover, which includes a front panel and side walls, a top plate and a bottom plate forming four sides on the same side; a rear cover, It includes a grid 25, and fixedly formed on the same side of the side wall, top plate and bottom plate, the side wall on the grid 25 just can be inserted into the space limited by the side wall of the front panel to realize the front cover and Snap-fit connection for the back cover. The grid 25 protrudes outwards corresponding to the air inlet to form a cylindrical buffer chamber, the buffer chamber is a bottom plate 21 relative to the air inlet, and the side wall 22 of the buffer chamber is made of a dense filter screen. Part of the airflow mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com