Water-based paint prepared by using slaked shell powder and calcium oxide unslaked lime

A water-based coating and shell powder technology, applied in chitin polysaccharide coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., can solve comprehensive properties such as adhesion and brushing performance, poor water and weather resistance, and cannot be suitable for mid-to-high-end markets. Use requirements, toxic and harmful chemical raw materials harm the environment, etc., to achieve the effects of low cost, reduced toxicity, and good environmental performance

Inactive Publication Date: 2011-06-01

斯丰义

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Existing water-based architectural paints are mainly acrylic latex paints and polyvinyl alcohol lime paints. The chemical synthesis of the former base material is complex, the cost is high, and the use of toxic and harmful chemical raw materials is harmful to

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with embodiment:

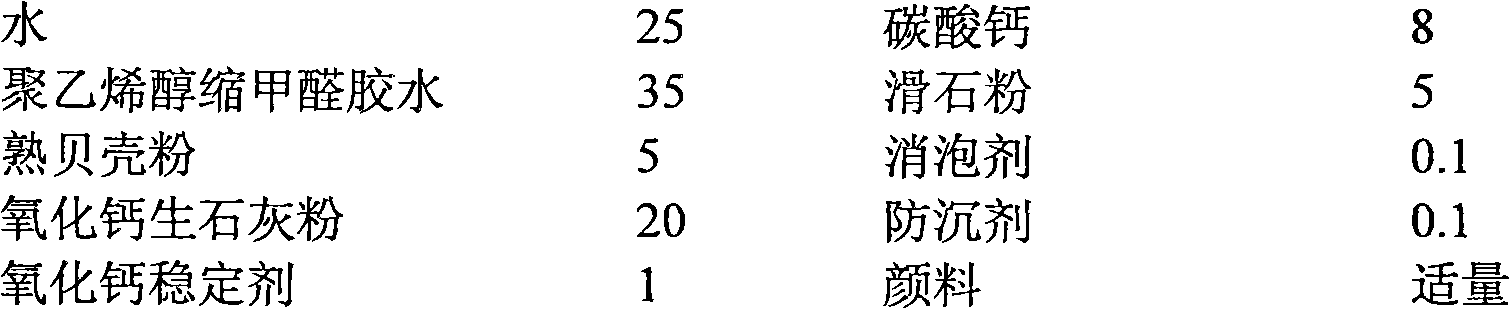

[0015] Water-based paint formulation:

[0016]

[0017] First digest cooked shell powder and calcium oxide quicklime powder in water, stir evenly, then pour in calcium oxide stabilizer, glue, calcium carbonate, talcum powder, defoamer, anti-sedimentation agent, pigment, and stir evenly for 30-40 minutes It is made by mixing thoroughly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention provides water-based paint prepared by using slaked shell powder and calcium oxide unslaked lime. Based on that solid component content is 10%-100% of paint of the slaked shell powder and the calcium oxide unslaked lime are added in a paint formula, wherein the slaked shell powder accounts for above 1% of total solid components, the rest solid components are a pigment and a filler; and an alkaline-resistant water-soluble binder which can be co-dissolved with the slaked shell powder and the calcium oxide unslaked lime and a corresponding auxiliary are used, and all the raw materials are evenly stirred, thus the water-based paint is obtained. The water-based paint has the advantages of strong adhesive power, low toxicity, good combination property and cheap cost.

Description

1. Technical field [0001] The invention relates to a water-based paint. 2. Background technology [0002] Existing water-based architectural paints are mainly acrylic latex paints and polyvinyl alcohol lime paints. The chemical synthesis of the former base material is complex, the cost is high, and the use of toxic and harmful chemical raw materials is harmful to the environment. Although the latter has low cost and good environmental performance, its The comprehensive properties such as adhesion, brushing performance, and water and weather resistance are poor, and they cannot meet the requirements of the mid-to-high-end market. [0003] In the 01105438.7 patent, the 200610025998.6 patent, and the 200910055838.X patent, I proposed "a water-based wall coating using shell powder", "a water-based coating using cooked shell powder and calcium hydroxide slaked lime", "using cooked shell powder Water-based coatings with lime calcium powder", proved in practice that it can be furt...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C09D129/14C09D105/08C09D5/14C09D5/08C09D5/00

Inventor 斯丰义

Owner 斯丰义

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap