Q345GJ series structural steel plates for ultra-thick building and production method thereof

A technology of Q345GJ, structural steel plate, applied in the direction of temperature control, etc., can solve problems such as difficulty in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, the Q345GJCZ35 finished steel with the chemical composition described in Table 1 below is obtained, and the process parameters and mechanical properties are shown in Table 4 below. , 5, 6.

[0025] Table 1 Chemical composition of steel in Example 1

[0026]

Embodiment 2

[0028] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, the Q345GJCZ35 finished steel with the chemical composition described in Table 2 below is obtained, and the process parameters and mechanical properties are shown in Table 4 below. , 5, 6.

[0029] Table 2 Chemical Composition of Steel in Example 2

[0030]

Embodiment 3

[0031] Example 3 Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, Q345GJCZ35 finished steel with the chemical composition described in Table 3 below is obtained, wherein the process parameters and mechanical properties are shown in See Tables 4, 5, and 6 below.

[0032] Table 3 Chemical Composition of Steel in Example 3

[0033]

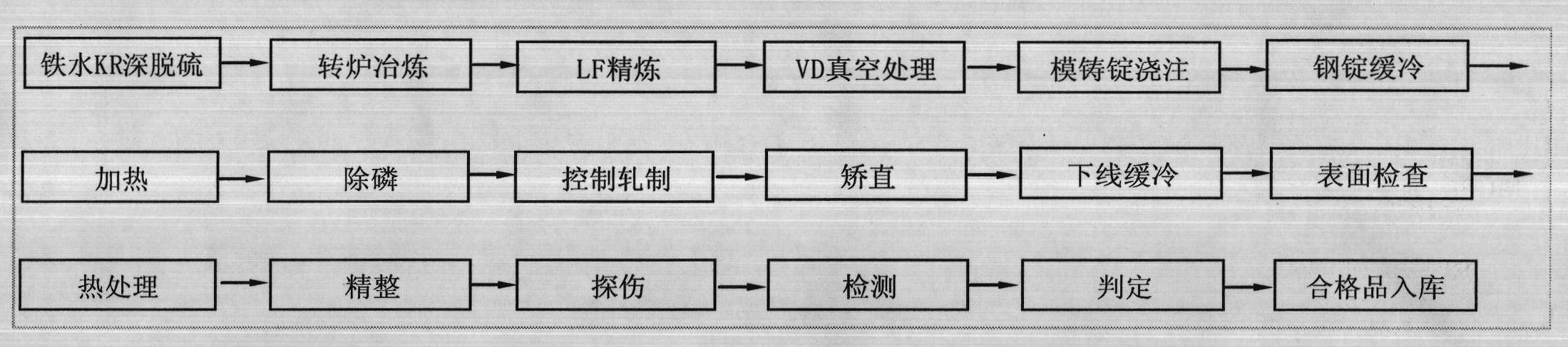

[0034] The process route of the present invention: molten iron KR deep desulfurization→converter smelting→LF refining→VD vacuum treatment→casting ingot pouring→steel ingot slow cooling→heating→phosphorus removal→controlled rolling→controlled cooling→controlled straightening→off-line slow cooling →surface inspection→heat treatment→finishing→flaw detection→testing→judgment→qualified product storage.

[0035] Steel-making composition design: Due to the thick thickness of the steel plate, it is difficult and important to ensure flaw detection and mecha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com