Method for distinguishing temperature of submersible motor based on lumped parameter model

A technology of centralized parameter model and submersible motor, which is applied in the direction of temperature measurement of moving solids, electrical digital data processing, special data processing applications, etc., can solve problems such as temperature information constraints, achieve small amount of calculation, realize soft measurement, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

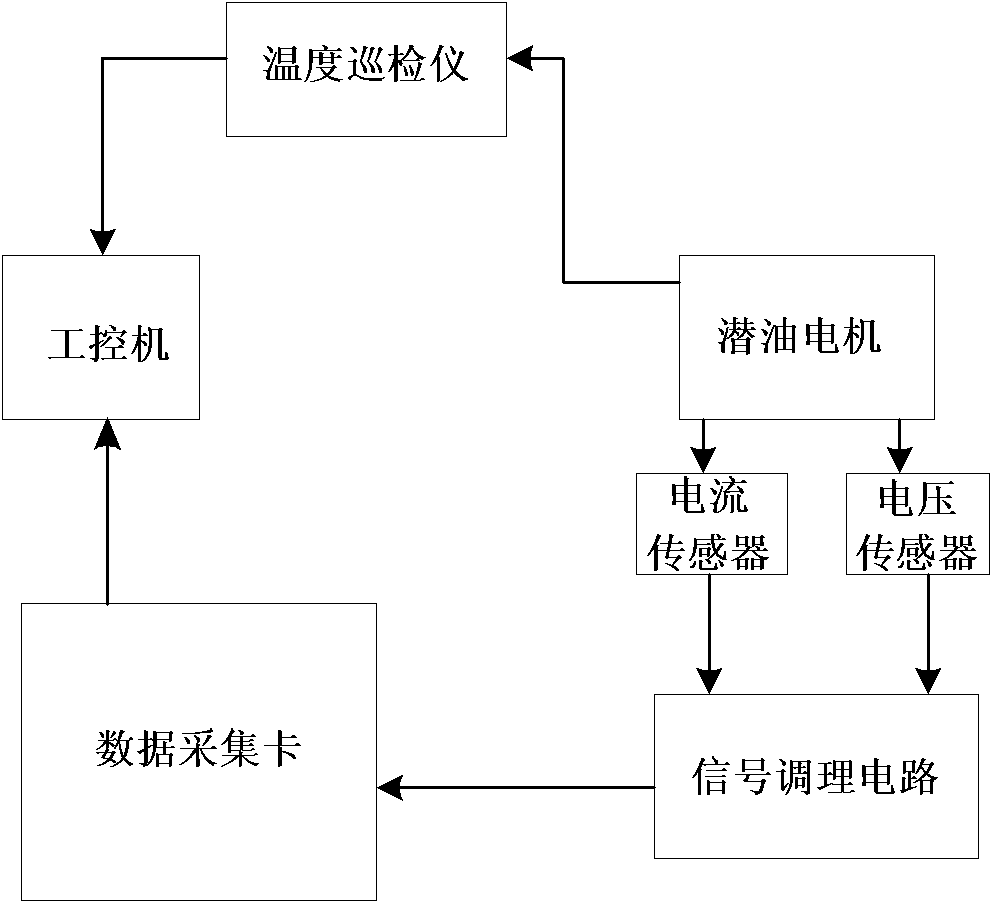

[0029] Specific implementation mode 1: the following combination Figure 1 to Figure 13 To describe this embodiment, this embodiment includes the following steps:

[0030] Step 1: Collect the three-phase stator voltage and the three-phase stator current of the submersible motor;

[0031] Step 2: Process the three-phase stator voltage and the three-phase stator current separately through the signal conditioning circuit, and use the processed signals as the stator original current input signal and the stator original voltage input signal;

[0032] Step 3: Use an industrial computer to calculate the total heating value u of the submersible motor based on the original stator current input signal and the stator original voltage input signal;

[0033] Step 4: In the industrial control computer, the total heating value u of the submersible motor is distributed to the components of the submersible motor according to the geometric size and energy consumption ratio of the components in the subme...

specific Embodiment approach 2

[0042] Specific implementation manner 2: the following combination Picture 12 with Figure 13 To explain this embodiment, this embodiment is a further explanation of the first embodiment. In step 3, the method for calculating the total heating value u of the submersible motor based on the stator original current input signal and the stator original voltage input signal using an industrial control computer is: The total heating value u of the submersible motor is the iron loss W i , Stator copper loss W s And rotor copper loss W r And the expression is u=W i +W s +W r ,

[0043] W i = [ 1 cR m - R d c X m ( X m + 2 x sc ) ] V p 2 - [ 1 - cX m X m + 2 x sc ] R d I p 2 ,

[0044] W s = R d I p 2 ,

[0045] W r = - R z X m ( X m + 2 x sc ) V p 2 + c 2 X m ...

specific Embodiment approach 3

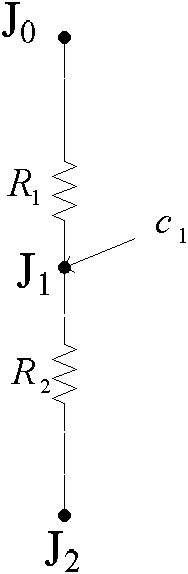

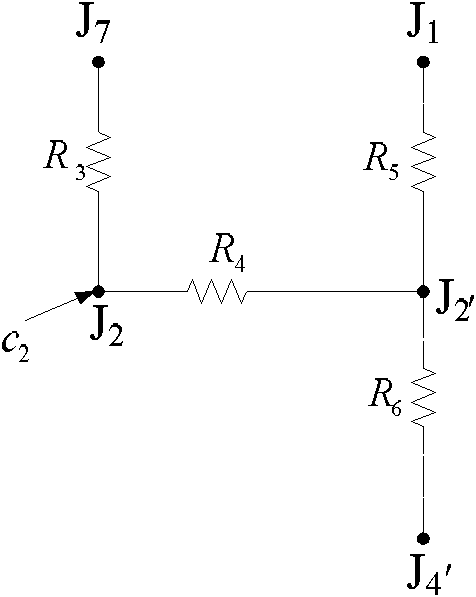

[0050] Specific implementation manner three: the following combination Figure 2 to Figure 11 This embodiment is described. This embodiment is a further description of the second embodiment. The equivalent circuit of each component of the submersible motor in step 4 is to simulate and calculate the thermal convection and thermal contact resistance of each component.

[0051] 41): Calculate the thermal contact resistance of the base as resistance R 1 And R 2 Resistance network, where the resistance R 1 And R 2 In series at node J 0 And J 2 Between, R 1 And R 2 The connection point is node J 1 , R 1 For direct measurement,

[0052] R 2 = 1 πh c Lr 1 ,

[0053] Where h c Is the contact coefficient between the base and the iron core, L is the length of the stator, r 1 Is the outer diameter of the stator;

[0054] Simulate the thermal convection of the base as c 1 :

[0055] c 1 = M e c e + 1 2 M f c f ,

[0056] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com