Method for processing back surface of wafer

A backside processing and wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of poor metallization quality and easy peeling of the metal layer, so as to improve the quality, improve the quality of the backside surface, and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

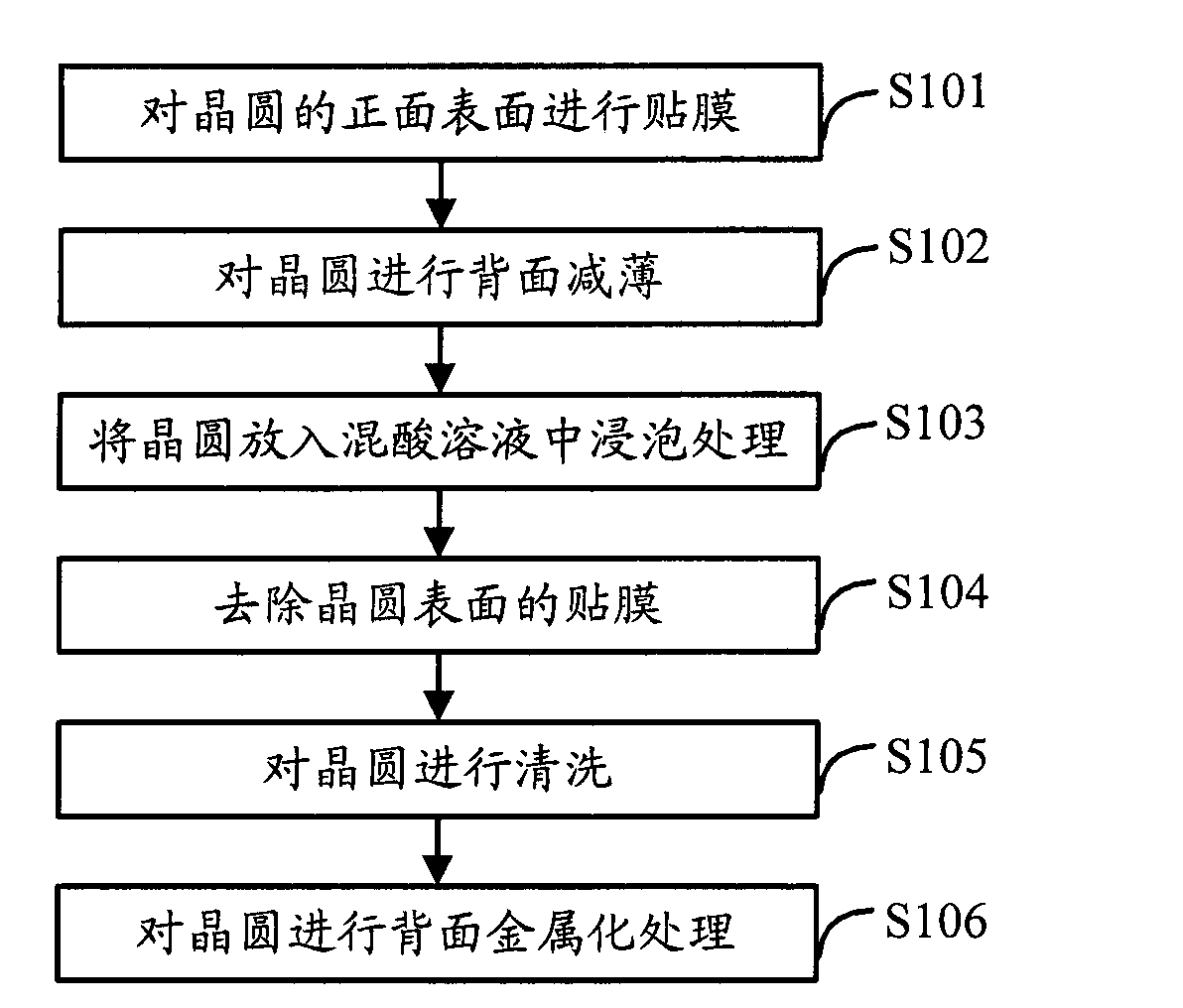

[0032] In order to improve the poor quality of the metallization layer on the back of the wafer in the prior art, and the problem that warping and deformation are prone to occur, the method for processing the back of the wafer provided by the embodiment of the present invention mainly involves the post-processing of the wafer. The thinning of the section processing technology, the improvement of the back gold and other related technological processes, the process is as follows figure 1 As shown, the execution steps are as follows:

[0033] Step S101: Applying a film to the front surface of the wafer.

[0034] The purpose of attaching the film to the front surface of the wafer is to protect the semiconductor devices on the front surface of the wafer from damage during subsequent processing.

[0035] Generally, a layer of acid-resistant blue film can be pasted on the front surface of the wafer. Apply film to the front surface of the wafer through a dedicated film mounter, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com