Method and system for parallel use of lithium battery modules

A battery management system, lithium battery technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of BMS circuit damage and high current, and achieve the effect of avoiding large current shock, reducing voltage difference, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

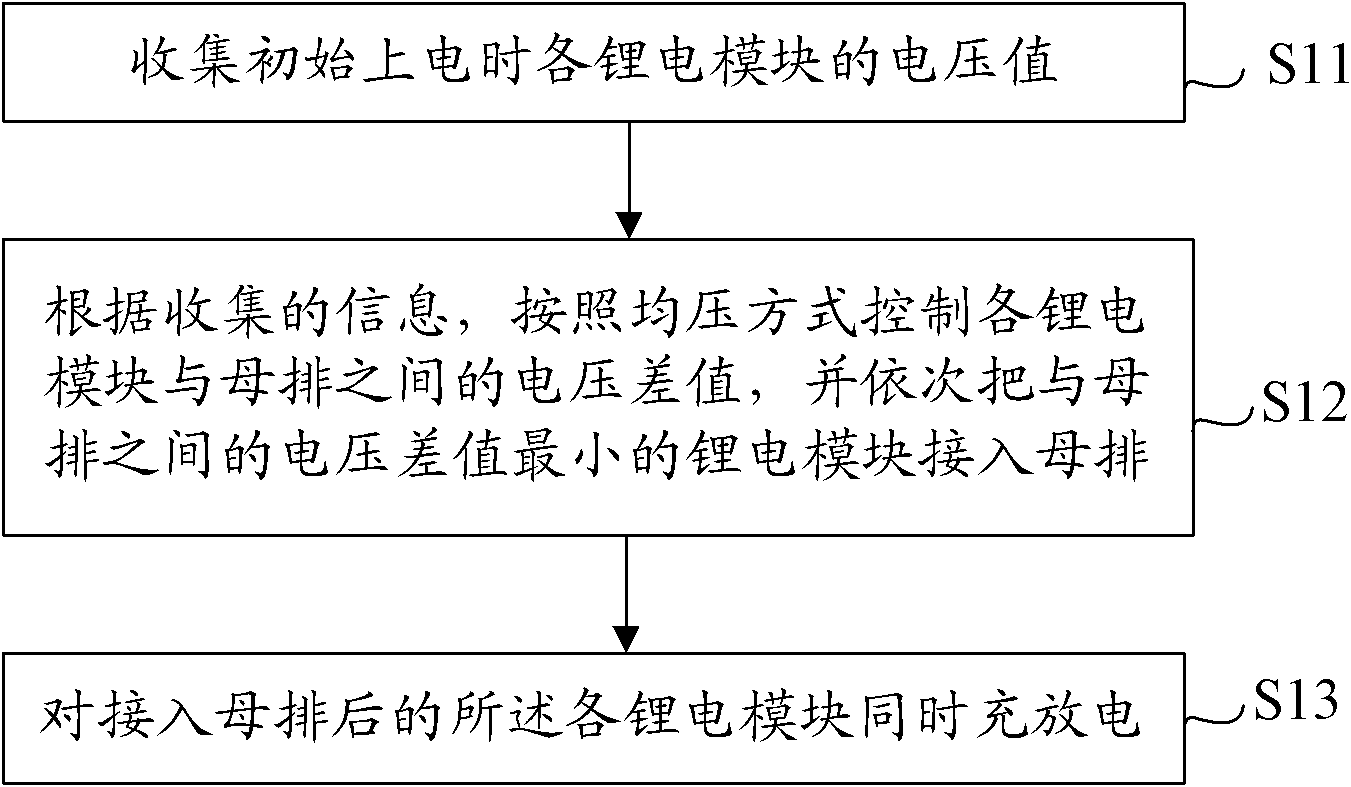

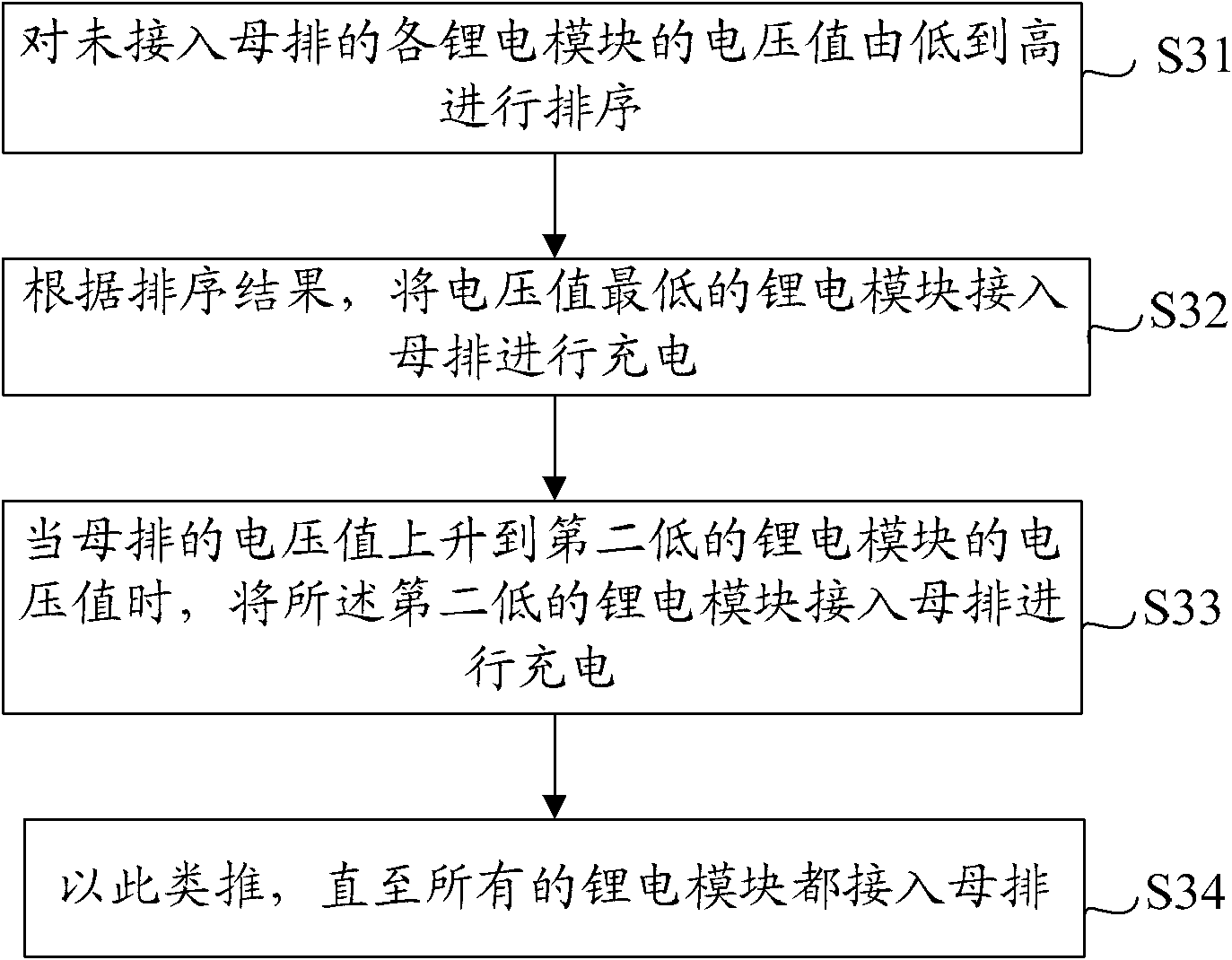

[0037] Embodiment 1: charging voltage equalization parallel mode

[0038] see image 3 , image 3 It is a schematic diagram of the charging voltage equalization parallel mode of this embodiment, including:

[0039] S31, sort the voltage values of each lithium battery module not connected to the busbar from low to high;

[0040] S32, according to the sorting result, connect the lithium battery module with the lowest voltage value to the busbar for charging;

[0041] S33, when the voltage value of the busbar rises to the voltage value of the second-lowest lithium battery module, connect the second-lowest lithium battery module to the busbar for charging;

[0042] S34, and so on, until all lithium battery modules are connected to the busbar.

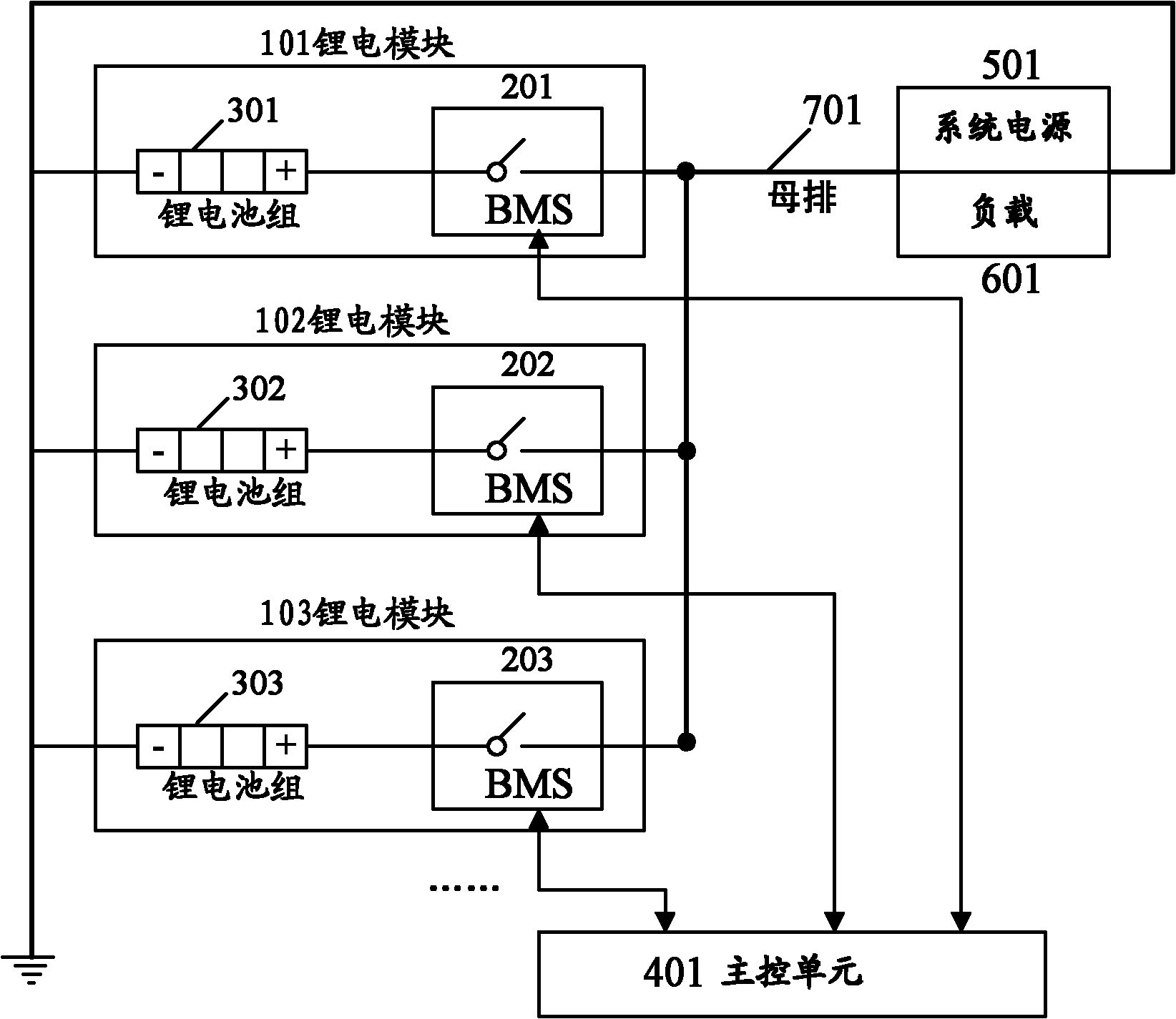

[0043] by figure 2 The shown system structure diagram is illustrated as an example. When the system is powered on initially, the BMS of all lithium battery modules disconnects the lithium battery modules from the busbar, and is in a...

Embodiment 2

[0044] Embodiment 2: Discharge voltage equalization parallel mode

[0045] see Figure 4 , Figure 4 It is a schematic diagram of the parallel discharge voltage equalization mode of this embodiment, including:

[0046] S41, sort the voltage values of each lithium battery module not connected to the busbar from high to low;

[0047] S42, according to the sorting result, connect the lithium battery module with the highest voltage value to the busbar for discharging;

[0048] S43, when the voltage value of the busbar drops to the voltage value of the second highest lithium battery module, connect the second highest lithium battery module to the busbar to discharge;

[0049] S44, and so on, until all lithium battery modules are connected to the busbar.

[0050] The hardware structure of the parallel discharge voltage equalization mode is the same as that of the charging voltage equalization parallel mode, but there are some minor differences in the software programming. sti...

Embodiment 3

[0051] Embodiment 3: Charge and discharge voltage equalization parallel mode

[0052] see Figure 5 , Figure 5 It is a schematic diagram of the parallel charging and discharging mode of voltage equalization in this embodiment, including:

[0053] S51, calculate the average voltage value of the voltage values of the lithium battery modules not connected to the busbar;

[0054] S52, connecting the lithium battery modules whose voltage value is lower than the average voltage value to the busbar in order from low to high for charging, until the voltage value of the busbar rises to the average voltage value;

[0055] S53, connect the lithium battery modules whose voltage value is higher than the average voltage value to the busbar in order from high to low for discharging, until the voltage value of the busbar drops to the average voltage value.

[0056] Specifically, the lithium battery module whose voltage value is lower than the average voltage value is connected to the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com