Current collector for nonaqueous electrolyte secondary battery, electrode for nonaqueous electrolyte secondary battery, method for manufacturing the current collector and the electrode, and nonaqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, electrode manufacturing, etc., can solve the problems of electrode wave, uneven stress, etc., and achieve improved flexibility and less characteristic deterioration. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

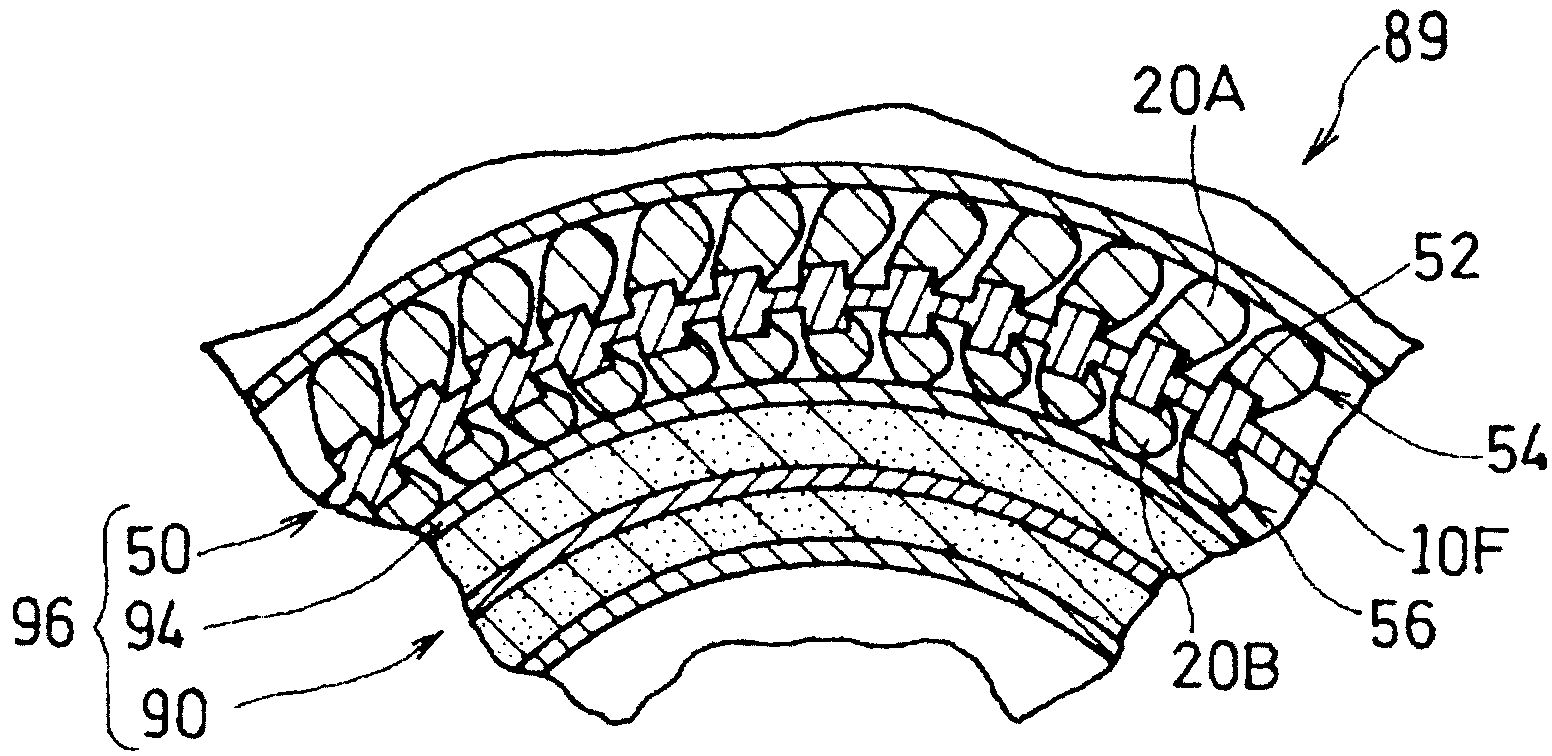

[0137] figure 1 A schematic configuration of a current collector for a nonaqueous electrolyte secondary battery according to Embodiment 1 of the present invention is shown in plan view. figure 2 A part thereof is shown enlarged by a perspective view.

[0138] The current collector 10 of the illustrated example includes a strip-shaped metal foil 11 and a plurality of protrusions 12 formed in a predetermined array on at least one surface of the metal foil 11 .

[0139] Such as figure 2 As shown, the protrusion 12 is formed in a substantially rhombic shape in plan view. More specifically, when the projection 12 is viewed from a direction perpendicular to the surface of the metal foil 11, both end portions in the long-axis direction (hereinafter referred to as long-axis direction ends) 12a and two end portions in the short-axis direction (Hereinafter referred to as short-axis direction end portion) 12b is formed so as to protrude outward with rounded corners. In addition, t...

Embodiment approach 2

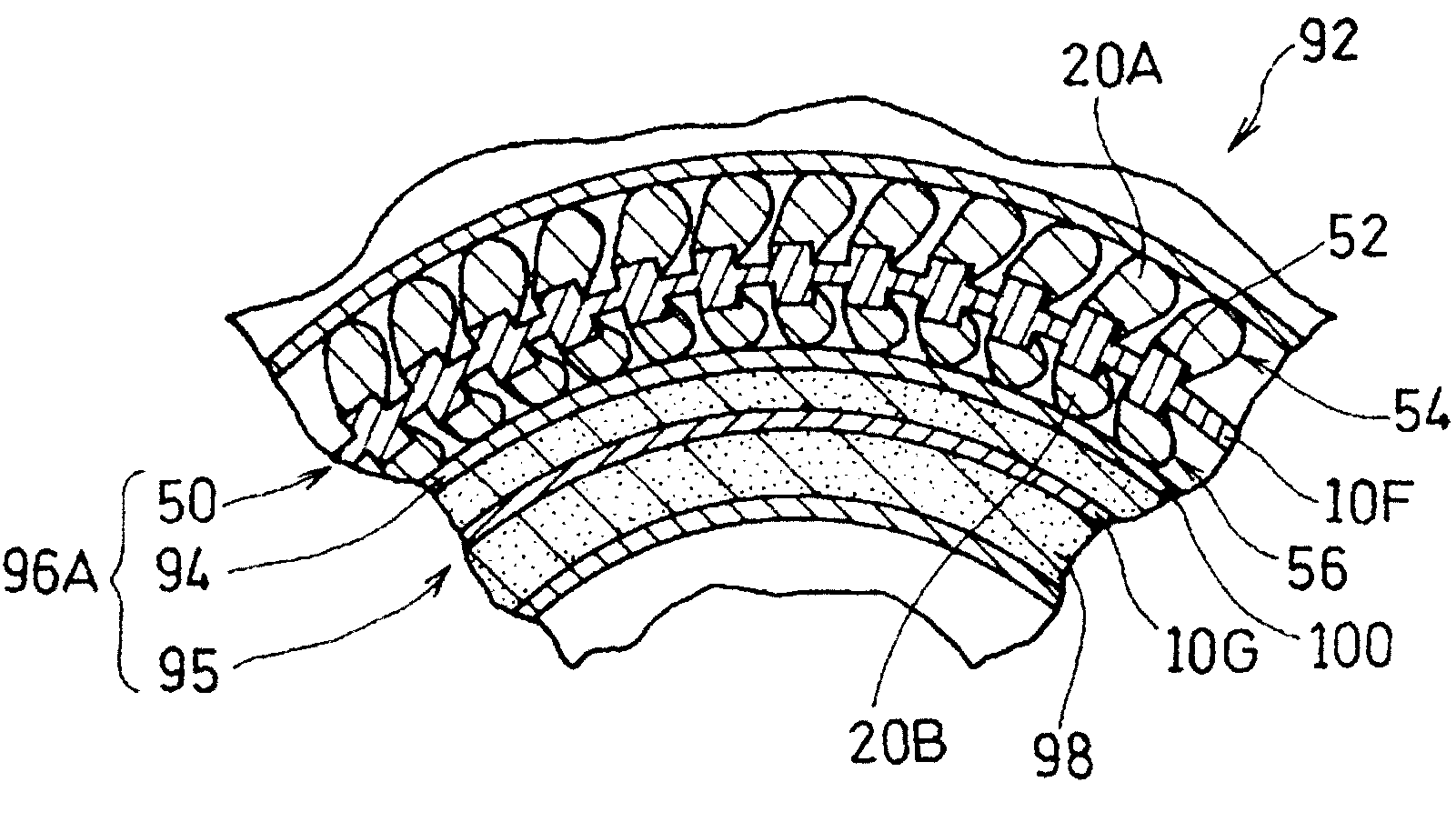

[0186] Next, Embodiment 2 of the present invention will be described. Figure 7 A part of the current collector according to Embodiment 2 of the present invention is enlargedly shown by a perspective view in .

[0187] exist Figure 7 shown in the current collector 10A, with figure 2 In the current collector 10 shown in the same manner, as the protrusion 26, the long-axis direction end 26a and the short-axis direction end 26b protrude outward with rounded corners, and the middle part between the long-axis direction end 26a and the short-axis direction end 26b 26c are all rounded back towards the inside.

[0188] Figure 7 The current collector 10A with figure 2 The current collector 10 is different in that the height of the long-axis direction end 26a of the protrusion 26 is higher than the height of the short-axis direction end 26b.

[0189] Moreover, between the two longitudinal-axis direction end parts 26a, the main upper surface part 26d whose height is equal to or ...

Embodiment approach 3

[0192] Next, Embodiment 3 of the present invention will be described. Figure 8 In FIG. 2 , a part of the current collector according to Embodiment 3 of the present invention is shown enlarged by a perspective view.

[0193] exist Figure 8 shown in the current collector 10B, with Figure 7 In the current collector 10A shown, similarly, as the protrusion 28, the long-axis direction end portion 28a and the short-axis direction end portion 28b protrude outward with rounded corners, and the intermediate portion between the long-axis direction end portion 28a and the short-axis direction end portion 28b 28c all rounded back inwardly. In addition, the height of the long-axis direction end portion 28a is higher than the height of the short-axis direction end portion 28b, and between the two long-axis direction end portions 28a, a main upper surface having a height equal to or higher than these end portions 28a is formed. Section 28d. On both sides of the main upper surface porti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com