Assembly and disassembly device and method for support roller of drum mixer

A cylinder mixing and idler technology, which is applied to lifting devices, lifting frames, metal processing and other directions, can solve the problems of difficult disassembly and assembly of idlers, poor stability and safety, etc., and achieves a simple method for disassembly and assembly of idlers and a structure. Stable, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

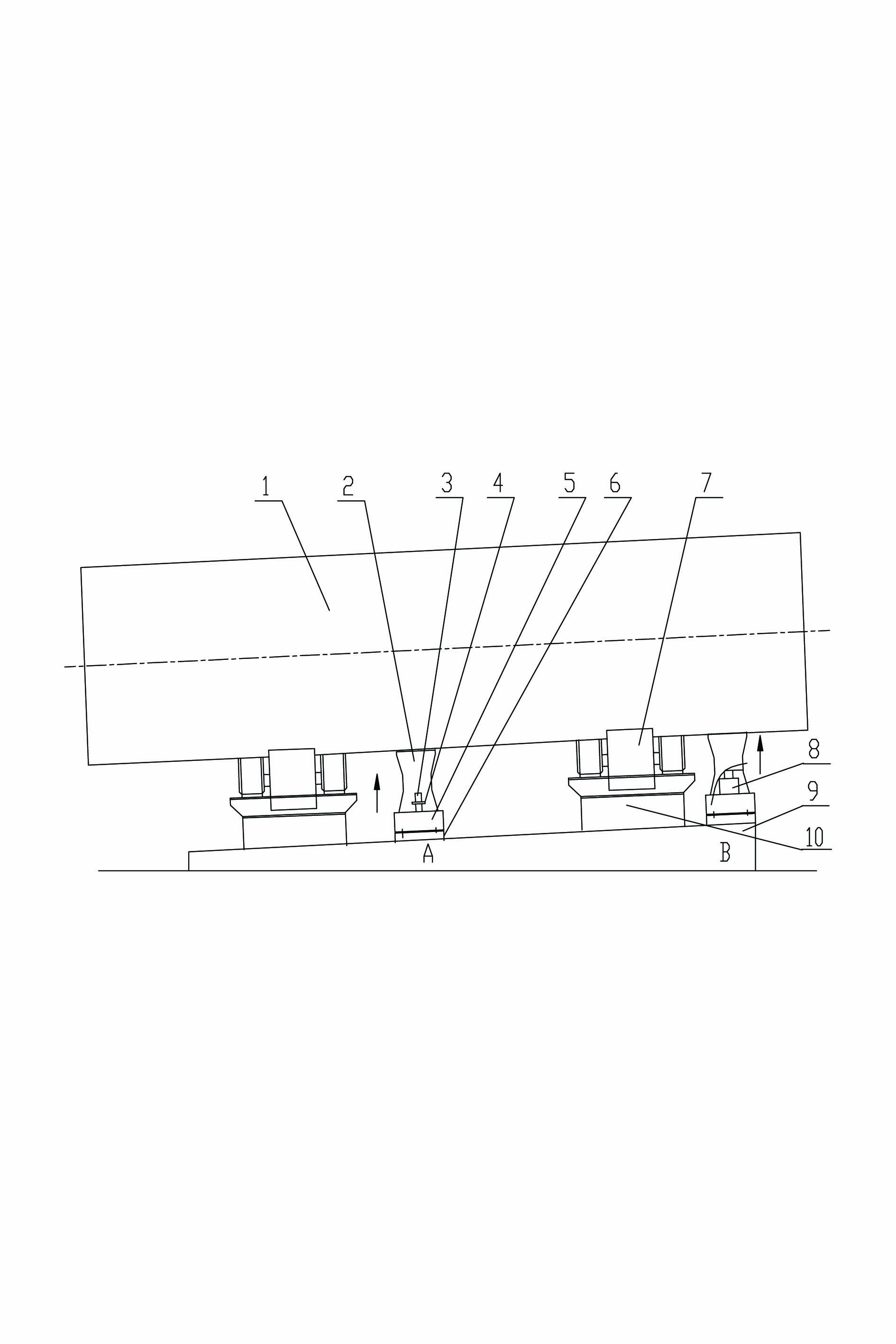

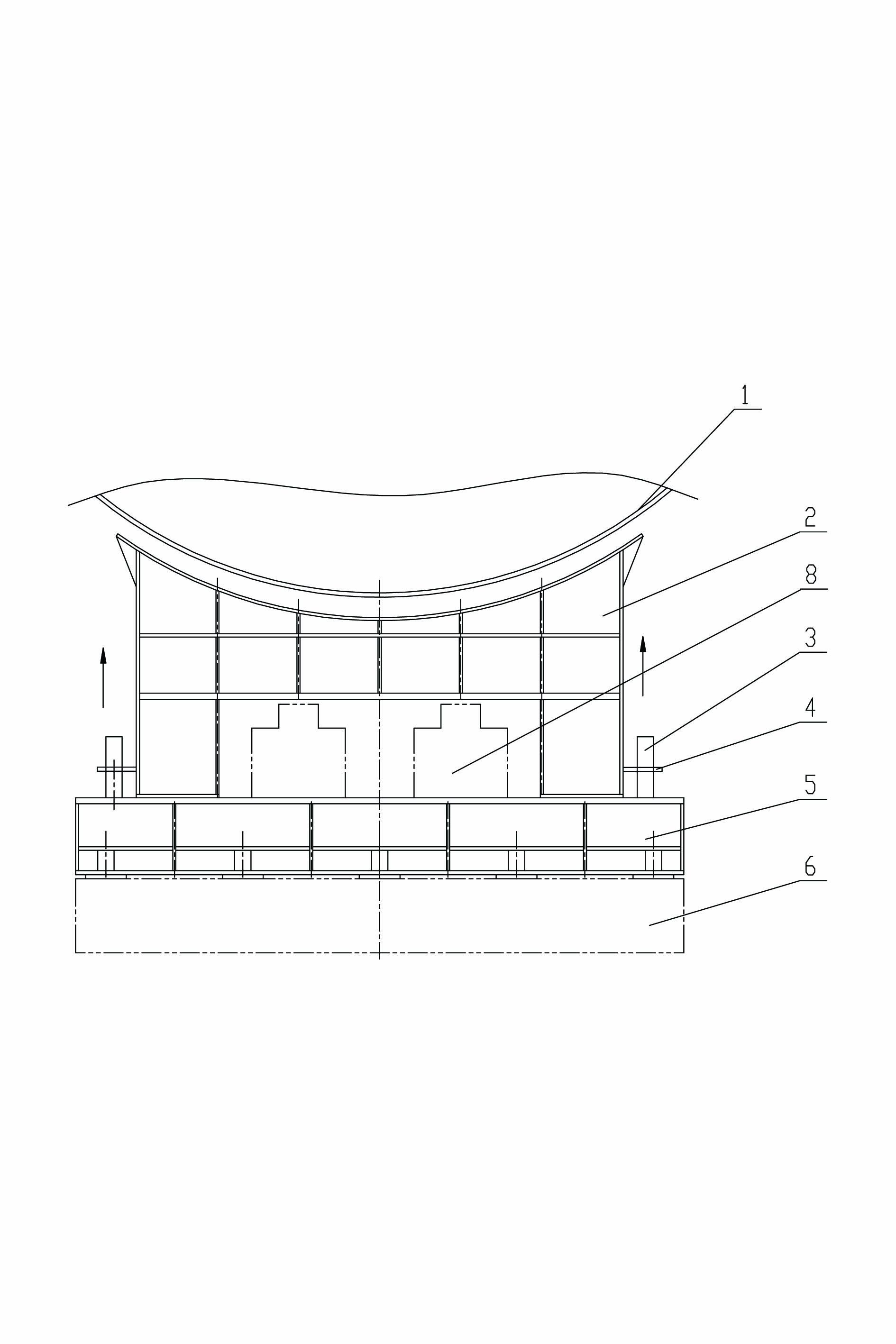

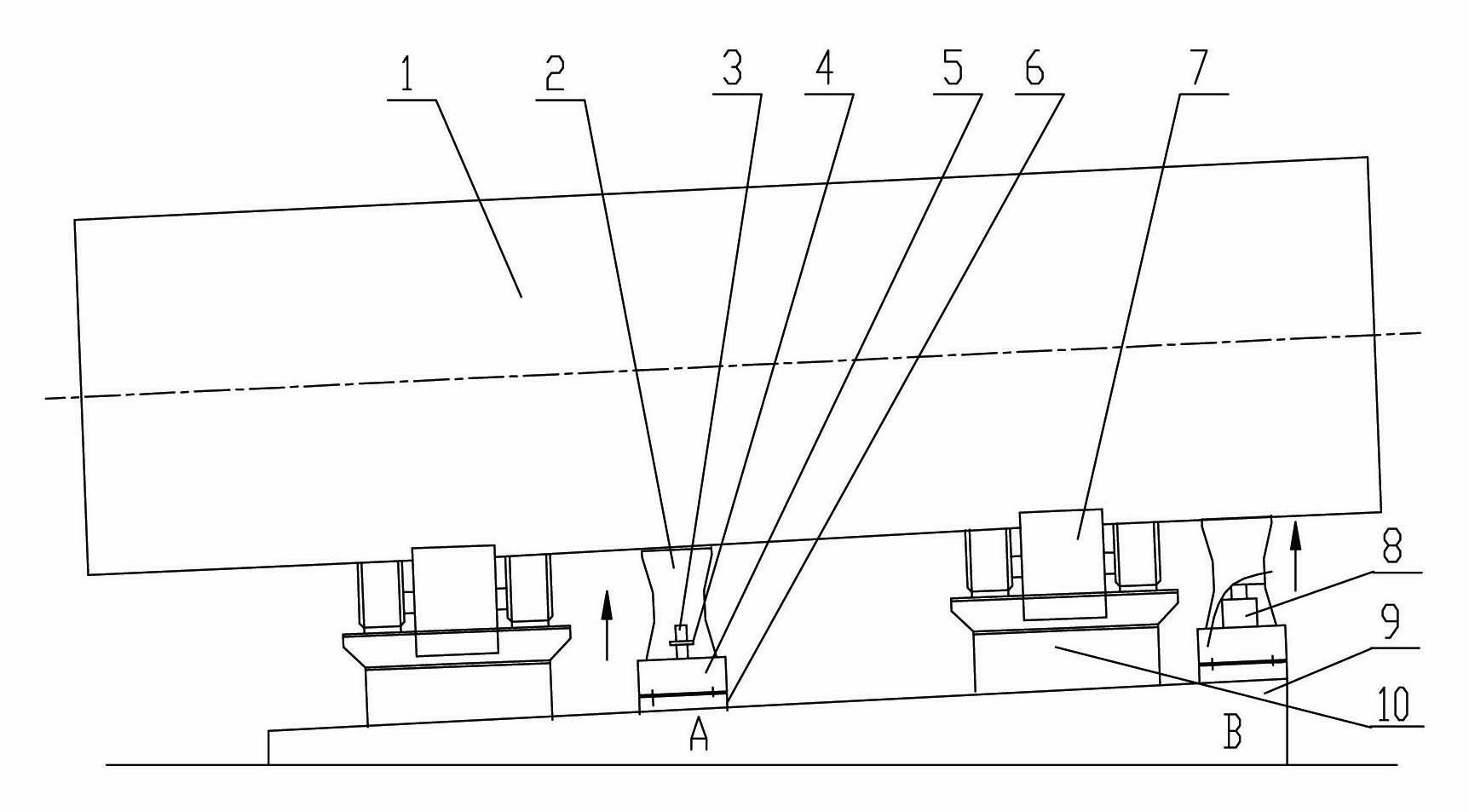

[0032] Such as figure 1 , figure 2 As shown, the dismounting device of the cylinder mixer roller of the present invention is characterized in that the base 6 of the dismounting device connected to the foundation 9 of the cylinder mixer is connected with the base 6 of the dismounting device The dismounting device base 5, a group of hydraulic jacks 8 arranged on the upper surface of the dismounting device base 5, and the bracket 2 abutting against the top of this group of hydraulic jacks 8 are respectively arranged on the sides of the bracket 2 The guide rod 3 is composed of a guide sleeve 4 slidingly connected with the guide rod 3 , and one end of the guide sleeve 4 is connected with the bracket 2 .

[0033] The upper surface of the bracket 2 is concave arc-shaped and matches the outer surface of the cylinder body 1 of the cylinder mixer. Increase its stability and security.

[0034] The working principle of the dismounting device of the cylinder mixer idler roller of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com