Iron oxide red epoxy amino base paint for coiled materials

A red epoxy ammonia and substrate technology, which is applied in the field of material painting, can solve problems such as poor covering power, and achieve the effects of reducing production costs, good hardness and adhesion, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

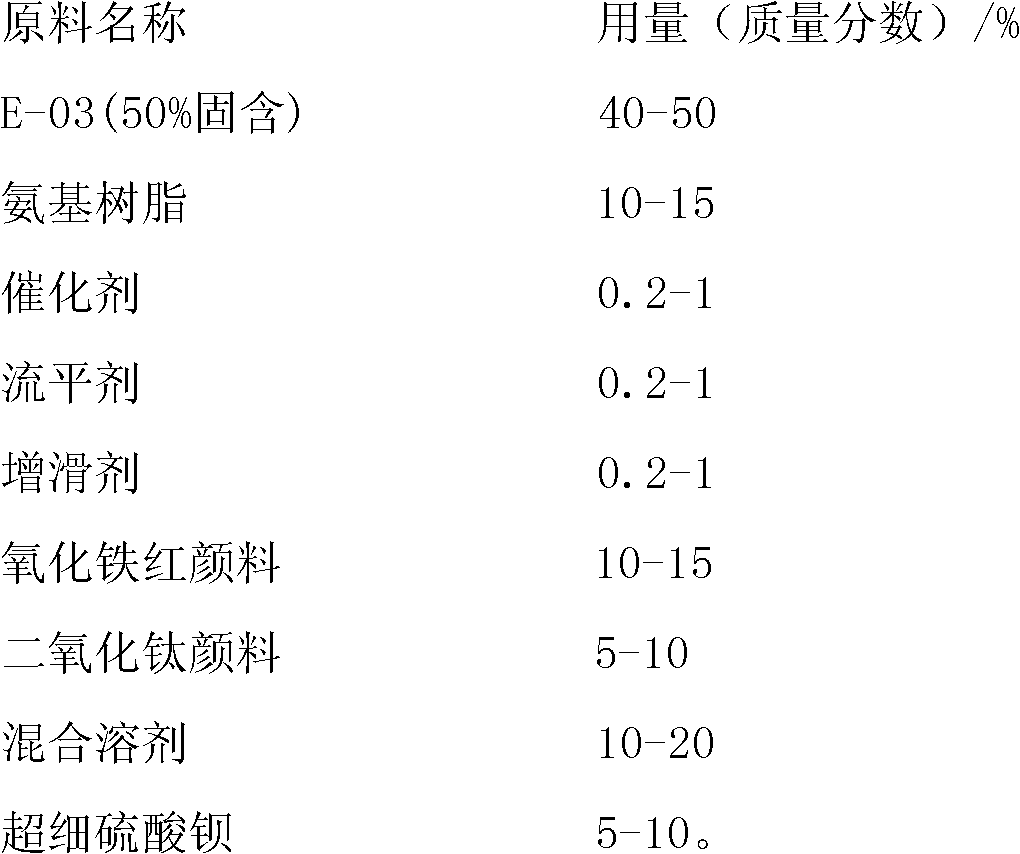

[0012] The dosage of various raw materials for the formulation of iron red epoxy amino primer for coils is as follows:

[0013]

[0014] After physical synthesis by stirring, it can be used.

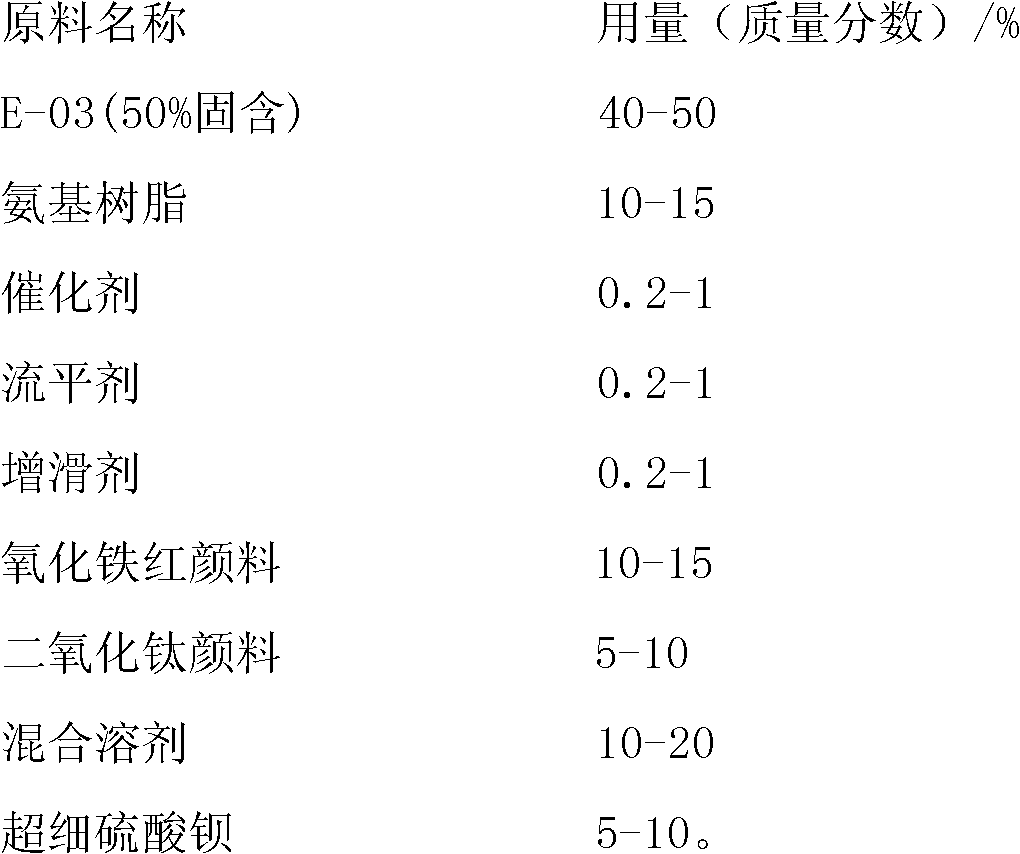

[0015] In order to further improve the characteristics and requirements of the product, the dosage of various raw materials for the formulation of the best iron red epoxy amino primer for coils is as follows:

[0016]

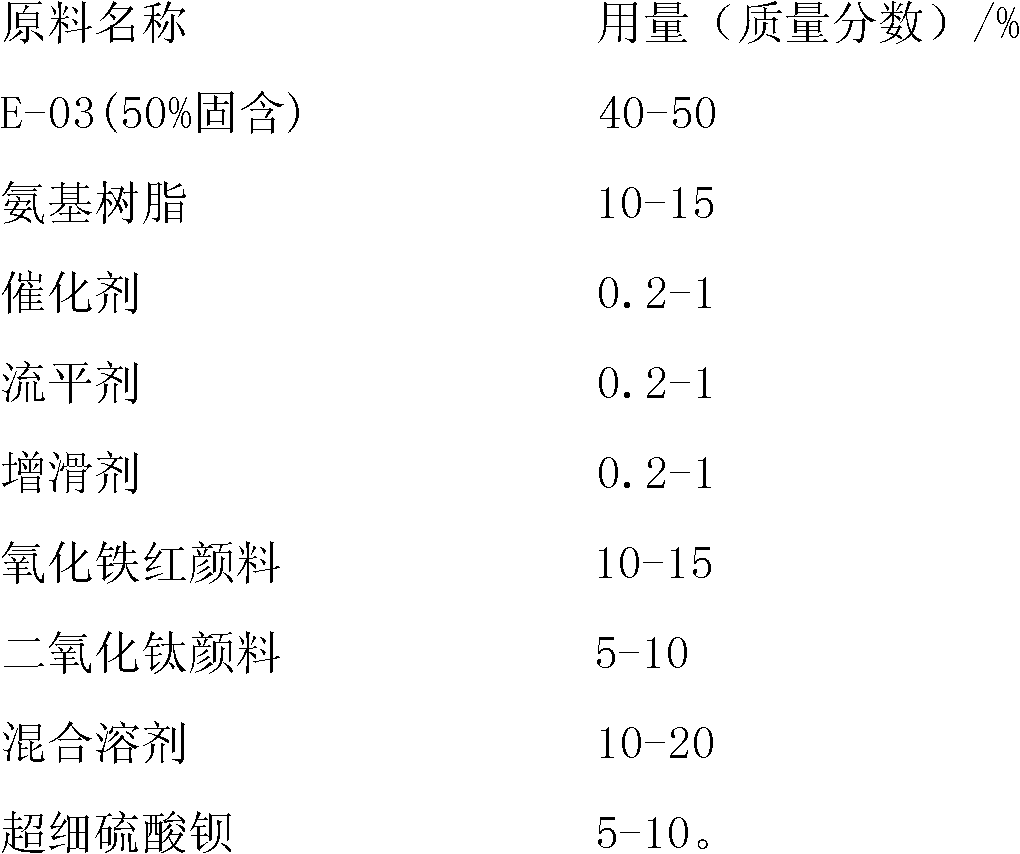

[0017]

[0018] After physical synthesis by stirring, it can be used.

[0019] By implementing the present invention, the following remarkable effects can be seen:

[0020] The invention not only has good hardness and adhesion, but also has excellent comprehensive performance, and other conventional physical and mechanical properties also meet the actual use requirements of color boards, solves the matching problem of red color boards, reduces paint consumption, and improves color boards. quality, reducing production costs.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap