Film coating device

A coating device and sputtering technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of voltage instability and affect product quality, and achieve the effect of voltage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings.

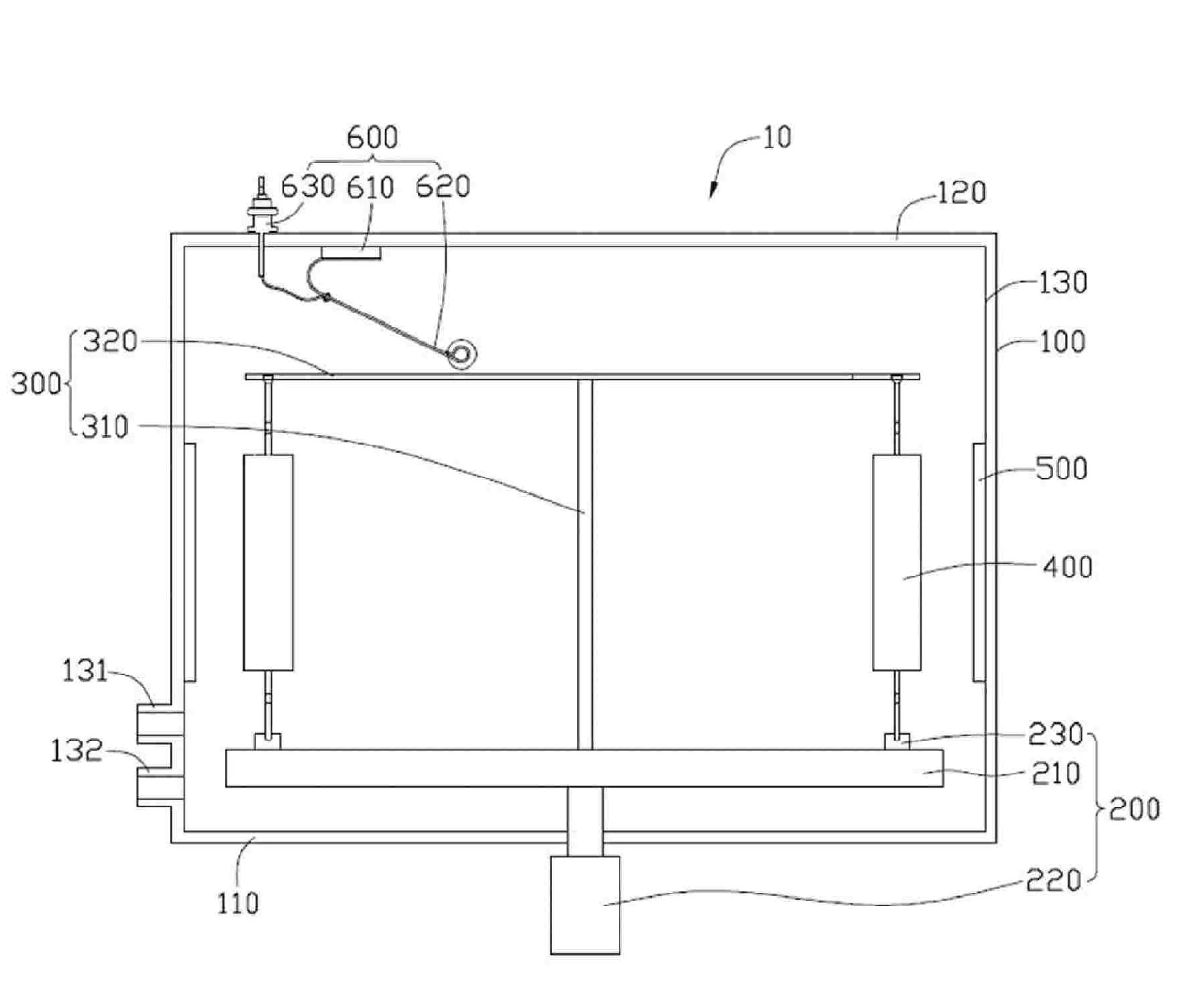

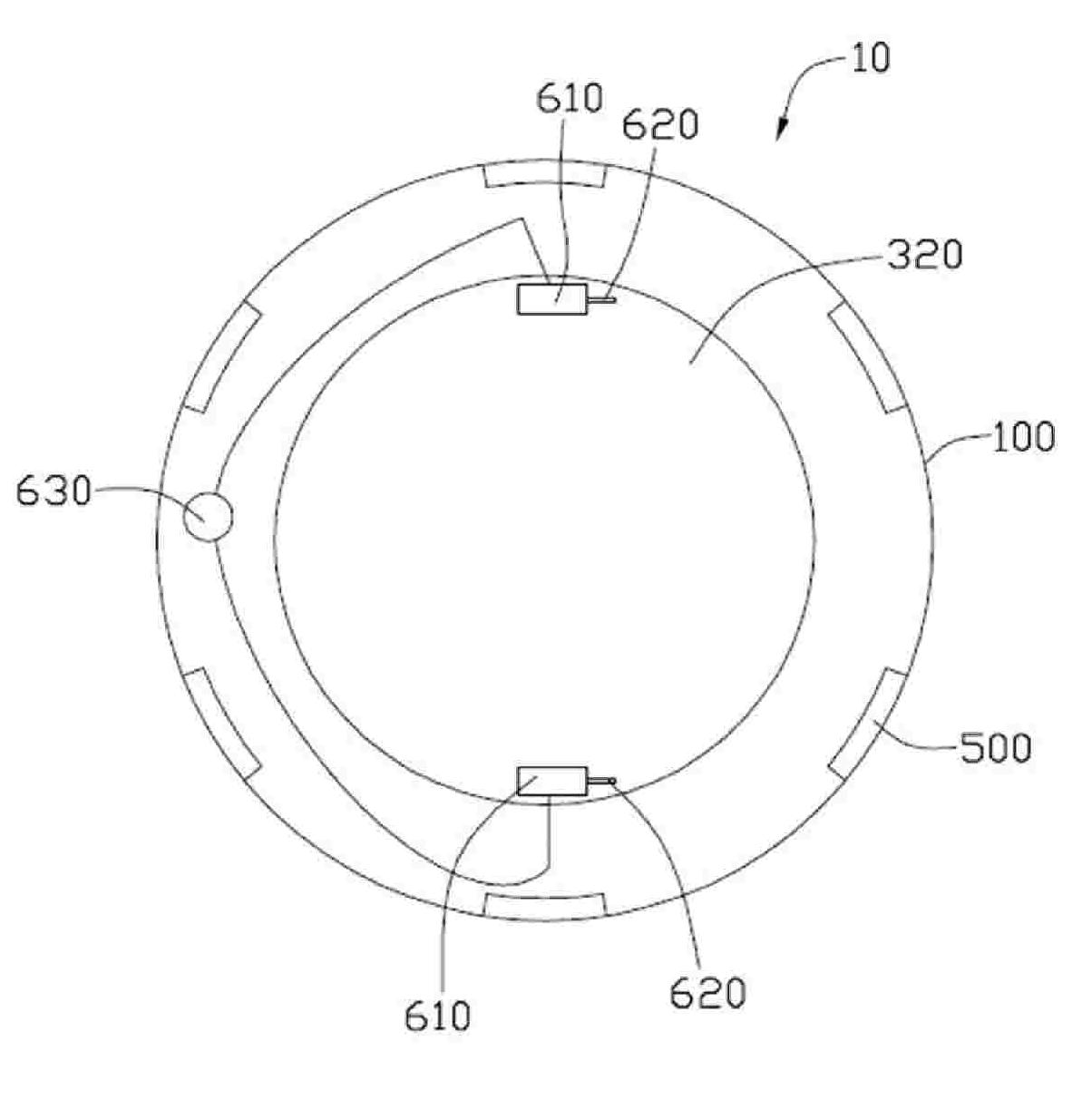

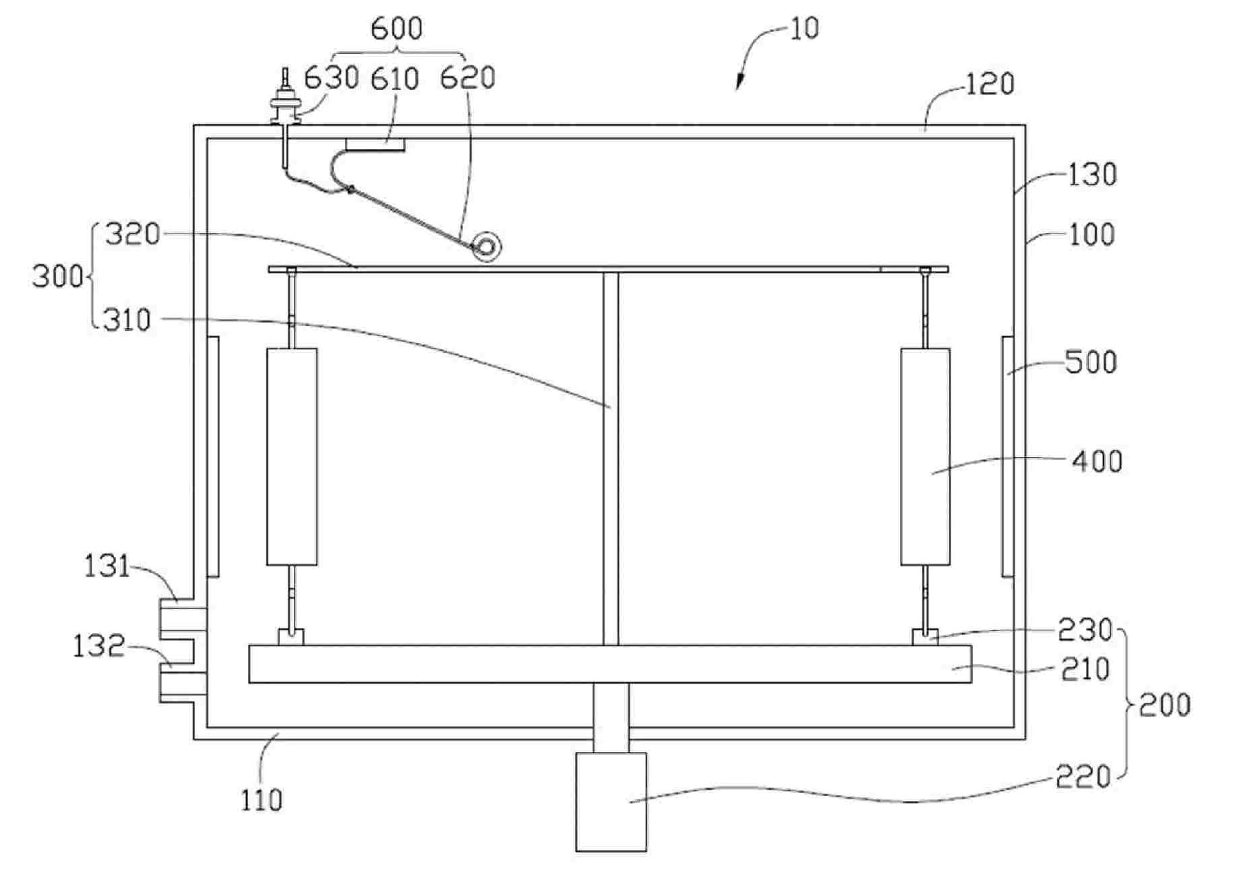

[0010] see figure 1 as well as figure 2 , a coating device 10 provided by a preferred embodiment of the present invention includes a sputtering chamber 100 , a rotating chassis 200 , a voltage introduction frame 300 , a plurality of rods 400 , targets 500 and brush modules 600 .

[0011] The sputtering chamber 100 includes a bottom wall 110 , a top wall 120 and a side wall 130 connecting the bottom wall 110 and the top wall 120 . An air inlet pipe 131 and an air extraction pipe 132 communicating with the sputtering chamber 100 are opened on the side wall 130 . The gas inlet pipe 131 is used for supplying the reaction gas required for sputtering into the sputtering chamber 100 , and the exhaust pipe 132 is used for vacuumizing the sputtering chamber 100 .

[0012] The rotating chassis 200 includes a turntable 210 , a turntable driving motor 220 and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com