Zoom lens

A zoom lens and focal length technology, applied in the field of zoom lenses, can solve the problems of insufficient zoom ratio, large number of lenses, and small amount of incoming light, etc., to achieve the effect of conveniently driving the lens group, reducing the weight of the lens, and reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

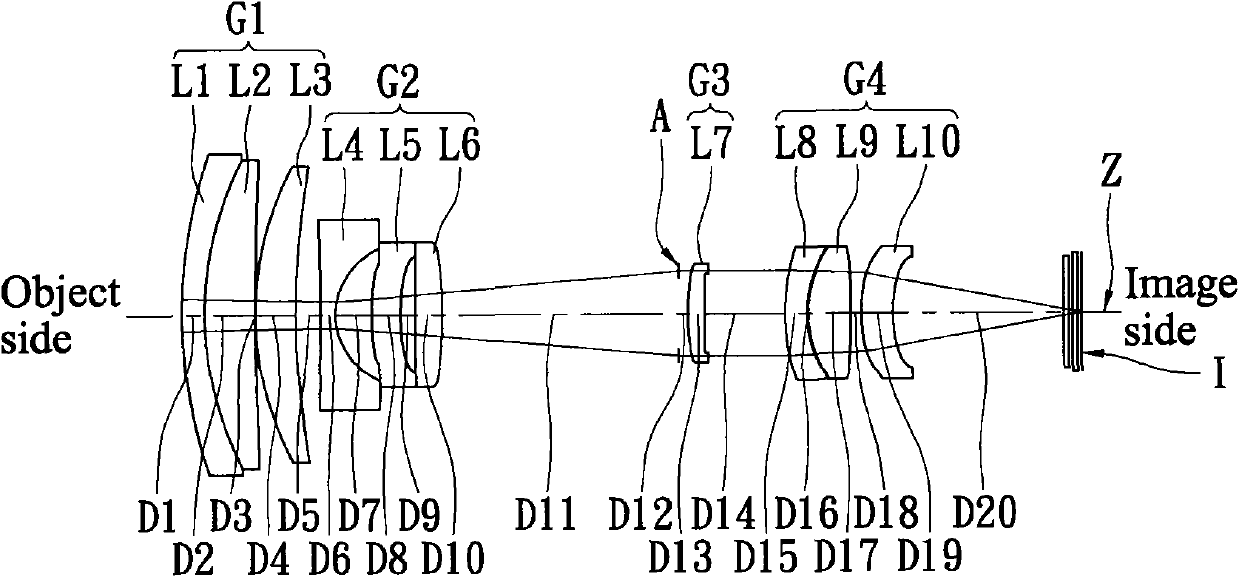

[0069] For the data of Example 1, please refer to the table below, where r represents the radius of curvature of each lens surface (numbered from S1 to S20), D represents the axial distance between each optical surface (numbered from D1 to D20), and nd represents The refractive index of each optical surface, vd represents the Abbe number of each optical surface (Abbe value, a numerical value representing the dispersion (chromatic dispersion) characteristic of a material).

[0070]

[0071]

[0072] The relationship between variables D5, D11, D14 and D20 relative to different zoom positions are as follows:

[0073]

[0074] Where f represents the focal length of the system corresponding to the wide-angle end, standard end and telephoto end, F NO Indicates the diaphragm aperture corresponding to the wide-angle end, standard end and telephoto end, and 2ω represents the viewing angle corresponding to the wide-angle end, standard end and telephoto end.

[0075] Furthermor...

Embodiment 2

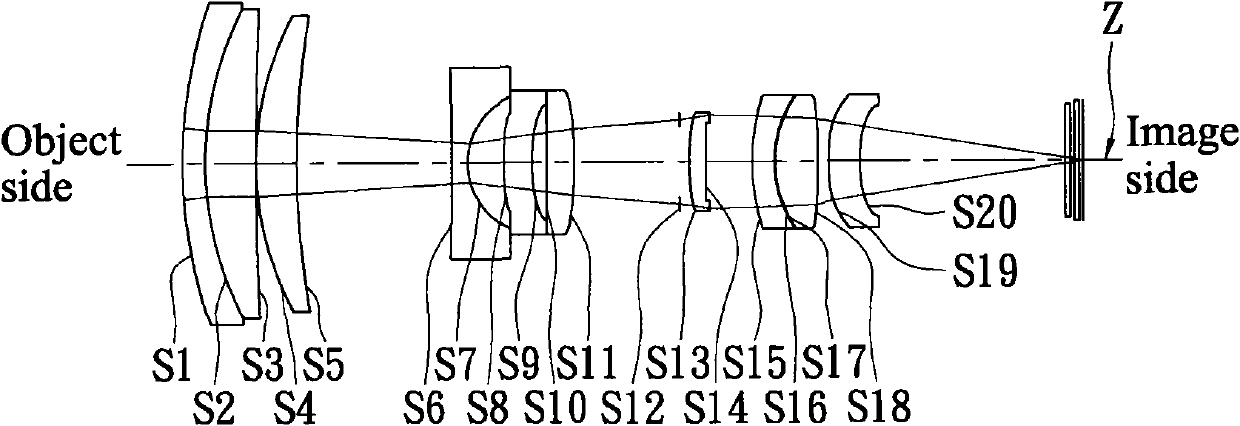

[0082] Please refer to the following table for the data of embodiment two:

[0083]

[0084]

[0085] The relationship between variables D5, D11, D14 and D20 relative to different zoom positions are as follows:

[0086]

[0087] Furthermore, in the lens, the optical surface numbers S8 to S11, S13, S14, and S17 to S20 are aspheric surfaces, and the data of the aspheric surface numbers are as follows:

[0088]

[0089]

[0090] see Figure 3A to Figure 3C , which respectively show that each lens group of the zoom lens according to the third embodiment of the present invention is at the wide-angle end ( Figure 3A ), standard position ( Figure 3B ) and the telephoto end ( Figure 3C ) Schematic diagram of lens configurations in three types. Therefore, the third embodiment is the same as the first embodiment, and is composed of 10 lenses. Figure 3D It is an image curve diagram representing the third embodiment when it is in the wide-angle mode; Figure 3E To...

Embodiment 3

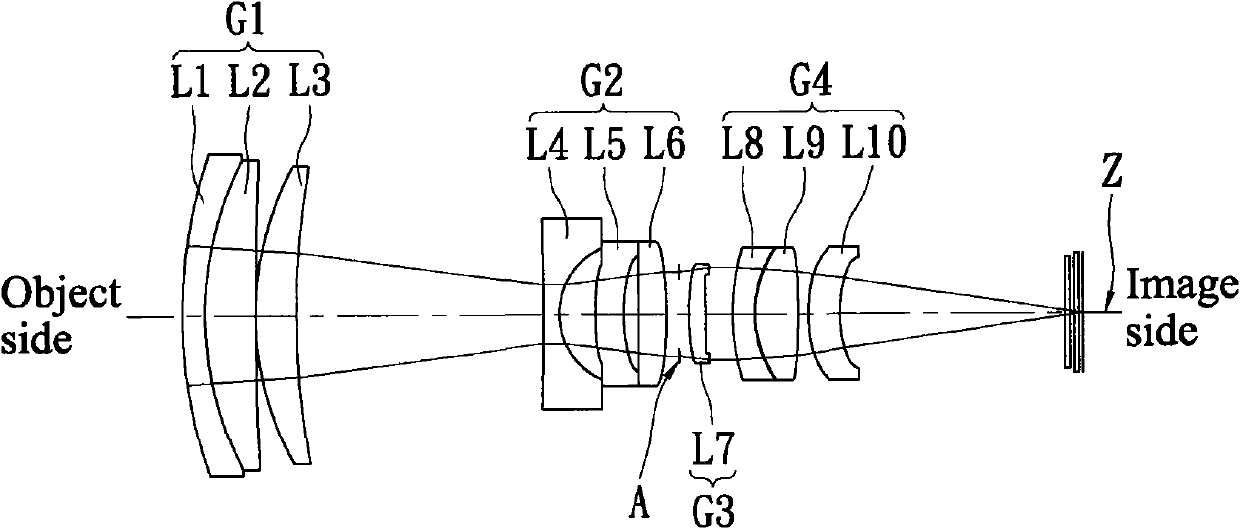

[0091] Please refer to the following table for the data of embodiment three:

[0092]

[0093]

[0094] Variables D5, D11, D14 and D20 relative to different zoom positions are as follows:

[0095]

[0096] Furthermore, in the lens, the optical surface numbers S8 to S11, S13, S14, and S17 to S20 are aspheric surfaces, and the data of the aspheric surface numbers are as follows:

[0097]

[0098] see Figure 4A to Figure 4C , which respectively show that each lens group of the zoom lens according to the fourth embodiment of the present invention is at the wide-angle end ( Figure 4A ), standard position ( Figure 4B ) and the telephoto end ( Figure 4C ) Schematic diagram of lens configurations in three types. Therefore, the fourth embodiment is the same as the first embodiment, and is composed of 10 lenses. Figure 4D It is an image graph showing the fourth embodiment when it is in the wide-angle mode; Figure 4E To represent the image curve diagram when the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap