Flexible light anode and preparation method thereof

A photoanode, flexible technology, applied in photovoltaic power generation, capacitor electrodes, semiconductor/solid-state device manufacturing, etc., can solve the problems of heavy battery weight, low electron transmission rate and low solar light transmission rate, and achieve weight reduction and ensure electron transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

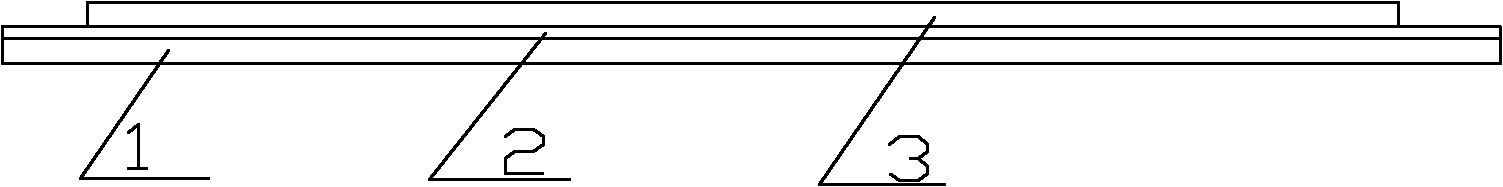

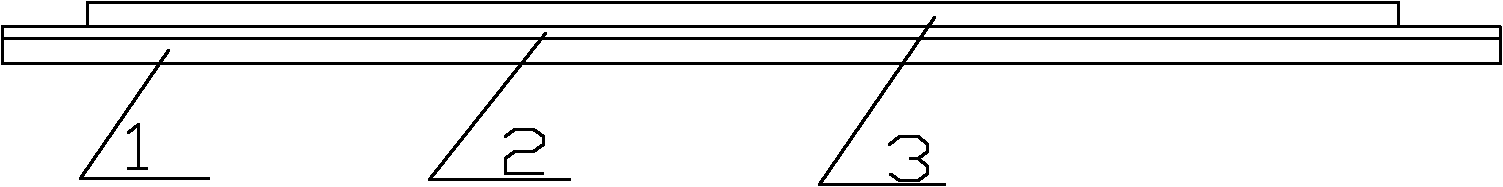

[0030] Below with reference to the accompanying drawings, by describing the embodiments, the specific embodiments of the present invention, such as the mutual positional relationship between the various parts involved, the process flow, etc., are further described in detail to help those skilled in the art understand the present invention. Ideas and technical solutions have a more complete, accurate and in-depth understanding.

[0031] Such as figure 1 The flexible photoanode includes a flexible high temperature resistant film 1 , a conductive layer 2 of a carbon nanotube film, and a photoanode layer 3 .

[0032] The material of the flexible high temperature resistant film 1 is polycarbonate (PC).

[0033] The conductive layer 2 of the carbon nanotube film is bonded on the flexible high temperature resistant film 1 .

[0034] The adhesive used is silicone.

[0035] The photoanode layer 3 is attached to the conductive layer 2 of the carbon nanotube film.

[0036] The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com