A method of preparing a high-conductivity aluminum-based composite material by utilizing low-resistivity carbon nanotubes

A technology of aluminum-based composite materials and carbon nanotubes, applied in the field of aluminum-based composite materials, can solve the problems of poor wettability between carbon nanotubes and aluminum liquid, low adhesion strength, and low conductivity of reinforced aluminum-based composite materials , to achieve the effect of improving bulk conductivity, excellent dispersion performance, and solving key problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

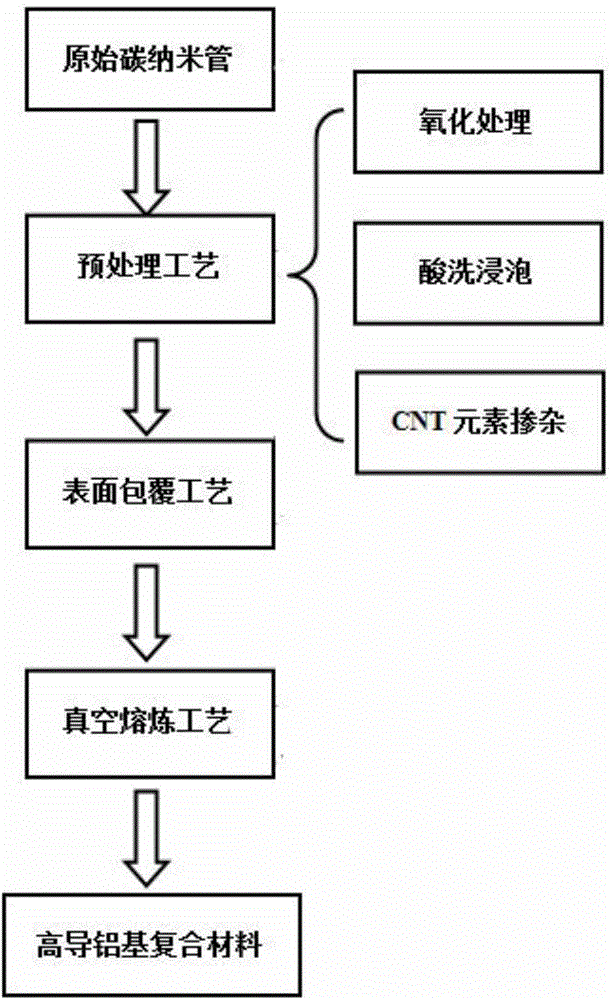

[0034] see figure 1 , the preparation method of the aluminum matrix composite material is realized in this way:

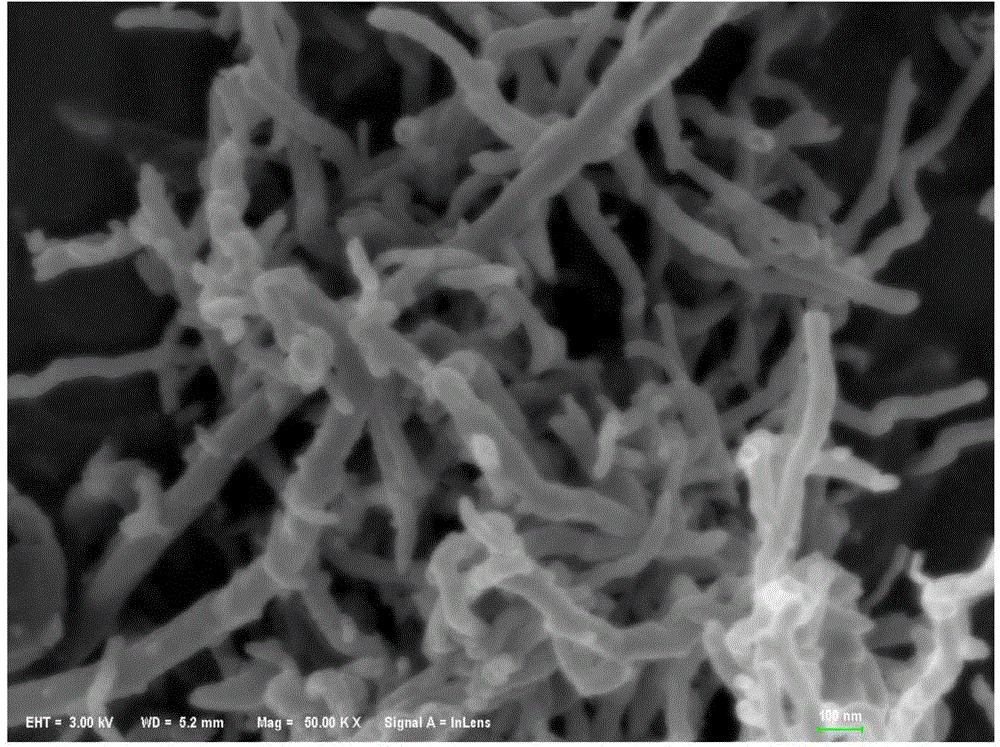

[0035] See step one figure 2 , the oxidation treatment process of carbon nanotubes:

[0036] Use the original multi-walled carbon nanotubes with a diameter of 60nm, put them into a muffle furnace or other high-temperature equipment, and oxidize them at a high temperature of 600°C for 30 minutes to remove amorphous carbon and some easily volatilized or decomposed at high temperatures material, and make some defects on the surface of the original carbon nanotubes re-grow and close, and powder A is obtained;

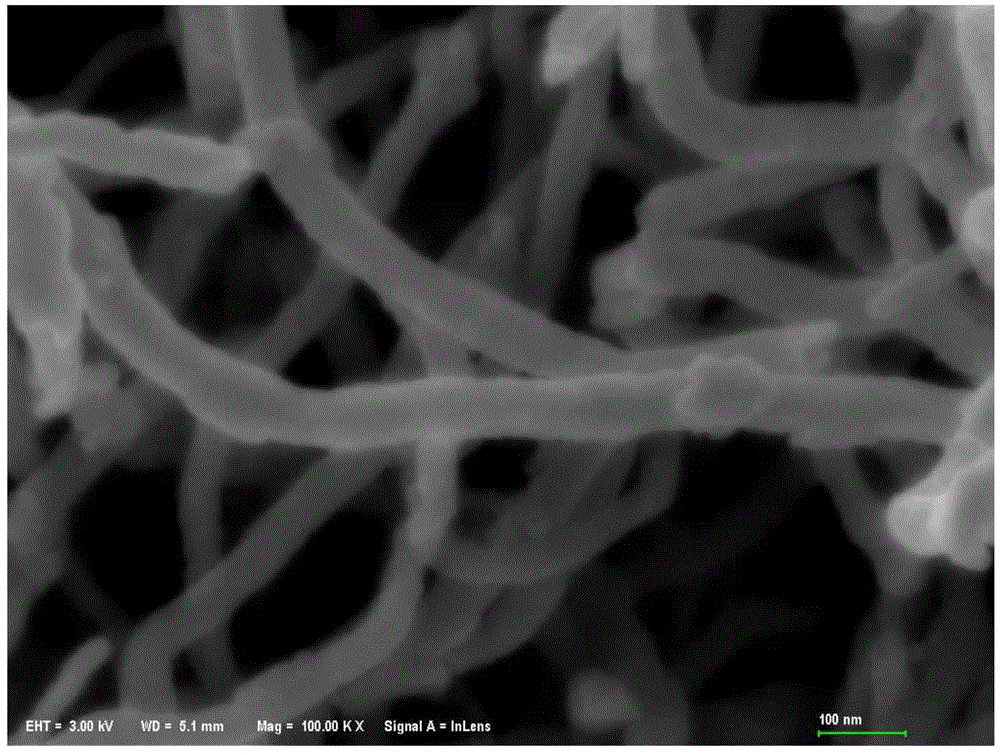

[0037] See step two image 3 , pickling and soaking process of carbon nanotubes:

[0038] Add the multi-walled carbon nanotubes treated by high-temperature oxidation into concentrated hydrochloric acid with a concentration of 36.5%, soak them, apply stirring at 100 rpm and mix for 10 minutes, take them out, wash them to neutrality, and obtain powder B that ...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the carbon nanotubes used in step 1 are single-walled carbon nanotubes with a diameter of 2 nm.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is that the halogen substance used in step 2 is simple iodine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com