Optical fiber failure positioning system and method

A fiber optic fault and positioning system technology, applied in transmission systems, electromagnetic wave transmission systems, electrical components, etc., can solve problems such as time-consuming and insufficient positioning accuracy, and achieve the effect of reducing monitoring blind spots and errors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

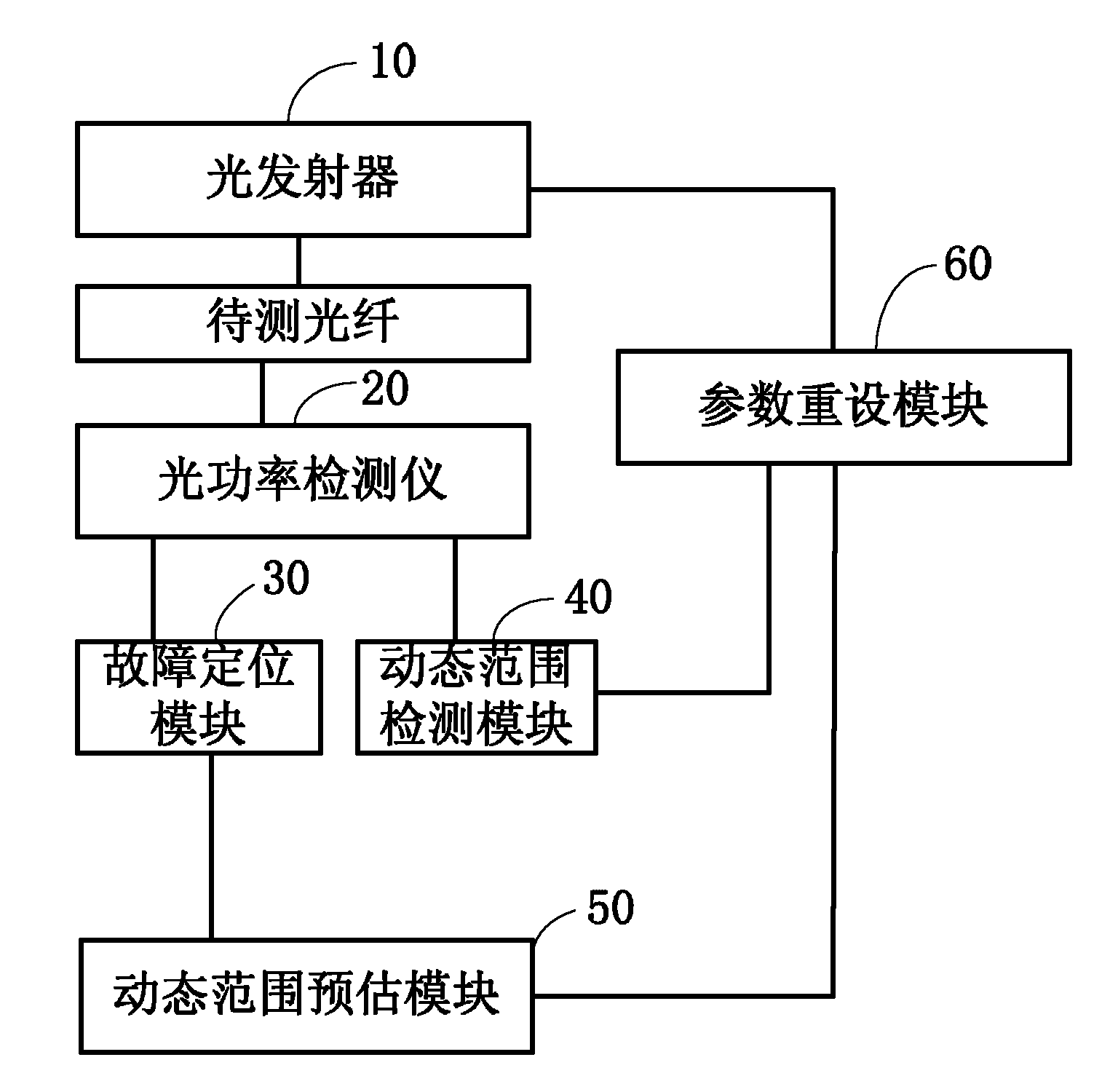

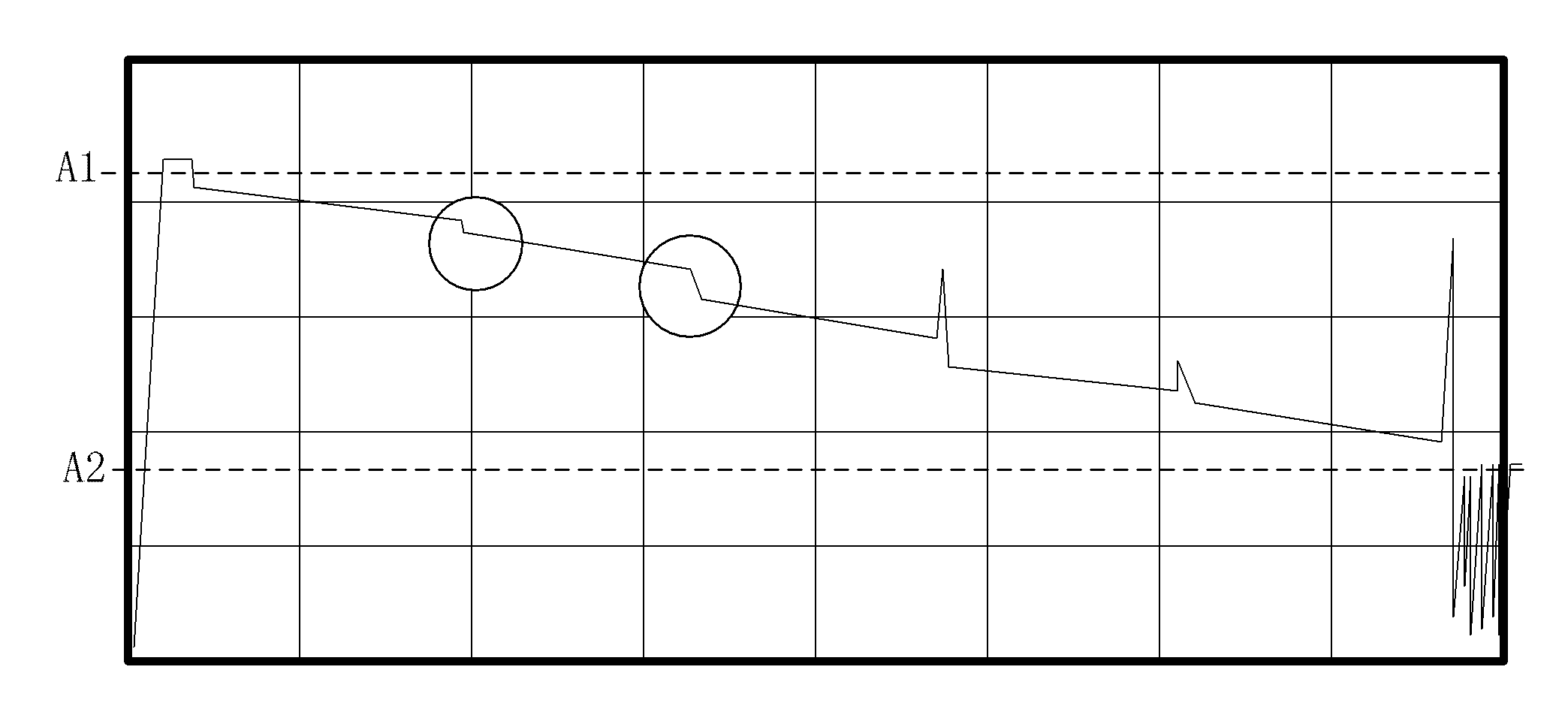

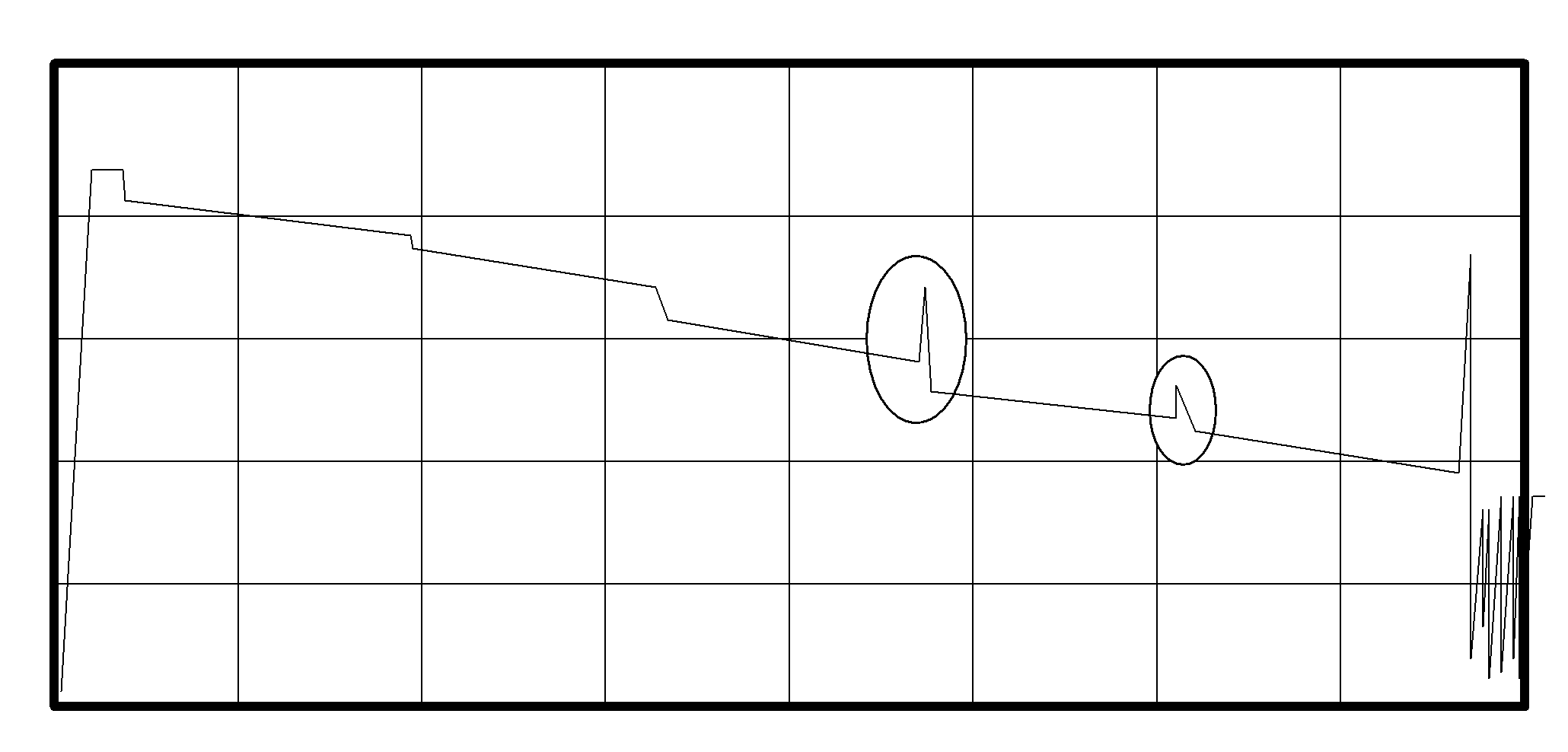

[0028] Please refer to figure 1 A preferred embodiment of the optical fiber fault location system of the present invention includes an optical transmitter 10 , an optical power detector 20 , a fault location module 30 , a dynamic range detection module 40 , a dynamic range estimation module 50 and a parameter reset module 60 .

[0029] The optical transmitter 10 is used to transmit the first test light to the optical fiber to be tested to be trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com