Sea chest cooler comprising an integrated antifouling system

A sea valve box and cooler technology, applied in the direction of damage protection, indirect heat exchangers, heat exchanger types, etc., can solve problems such as susceptibility to interference, complicated technical investment, etc., and achieve the effect of saving energy costs and saving purchase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

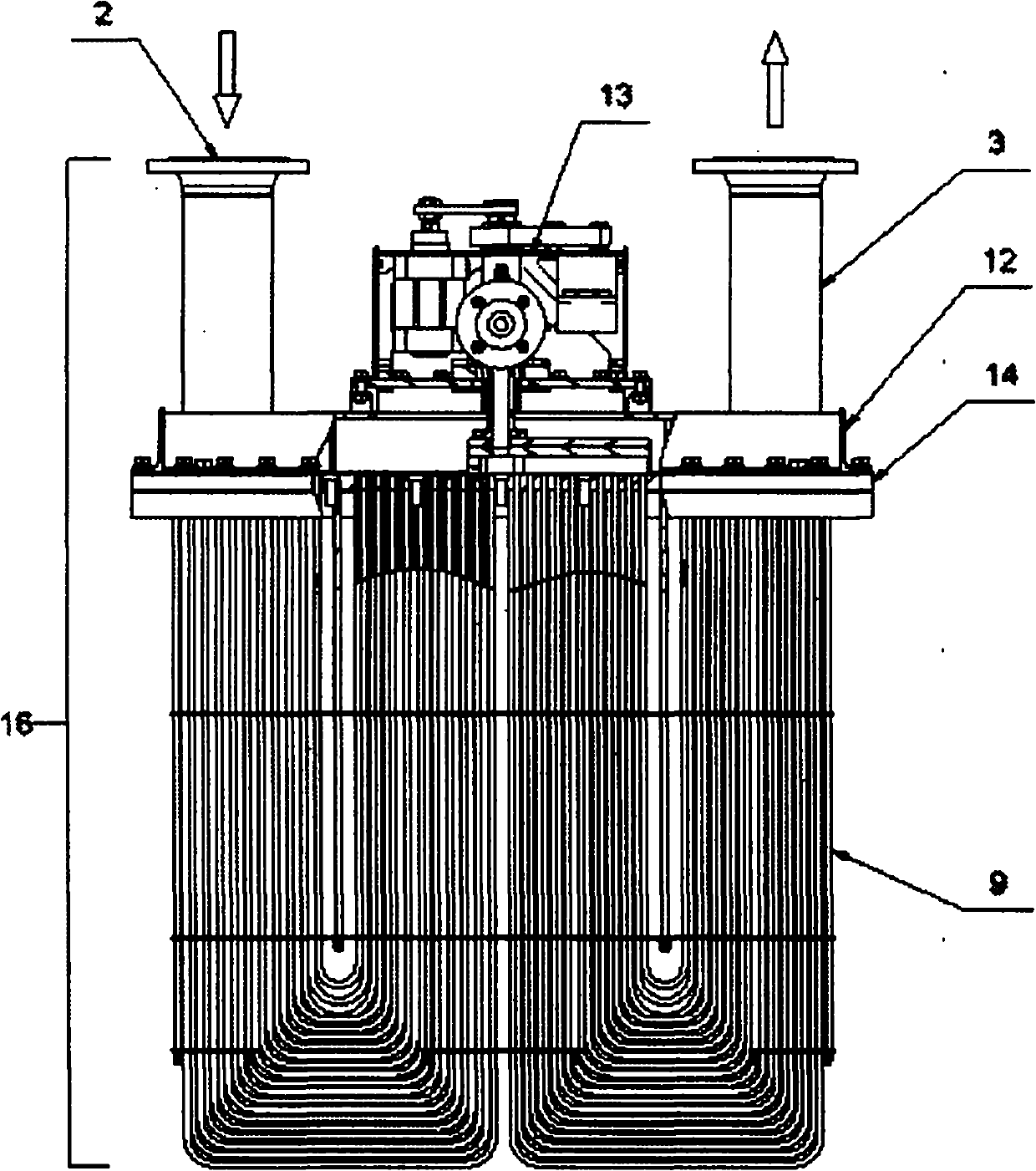

[0024] Figure 1a A sea chest cooler 16 is shown with its main components such as the tube bundle 9, cover 12 and integrated TAS unit 13. The engine cooling water enters the space formed by the cover 12 and the tube plate 14 of the sea chest cooler 16 via the inlet connection 2 .

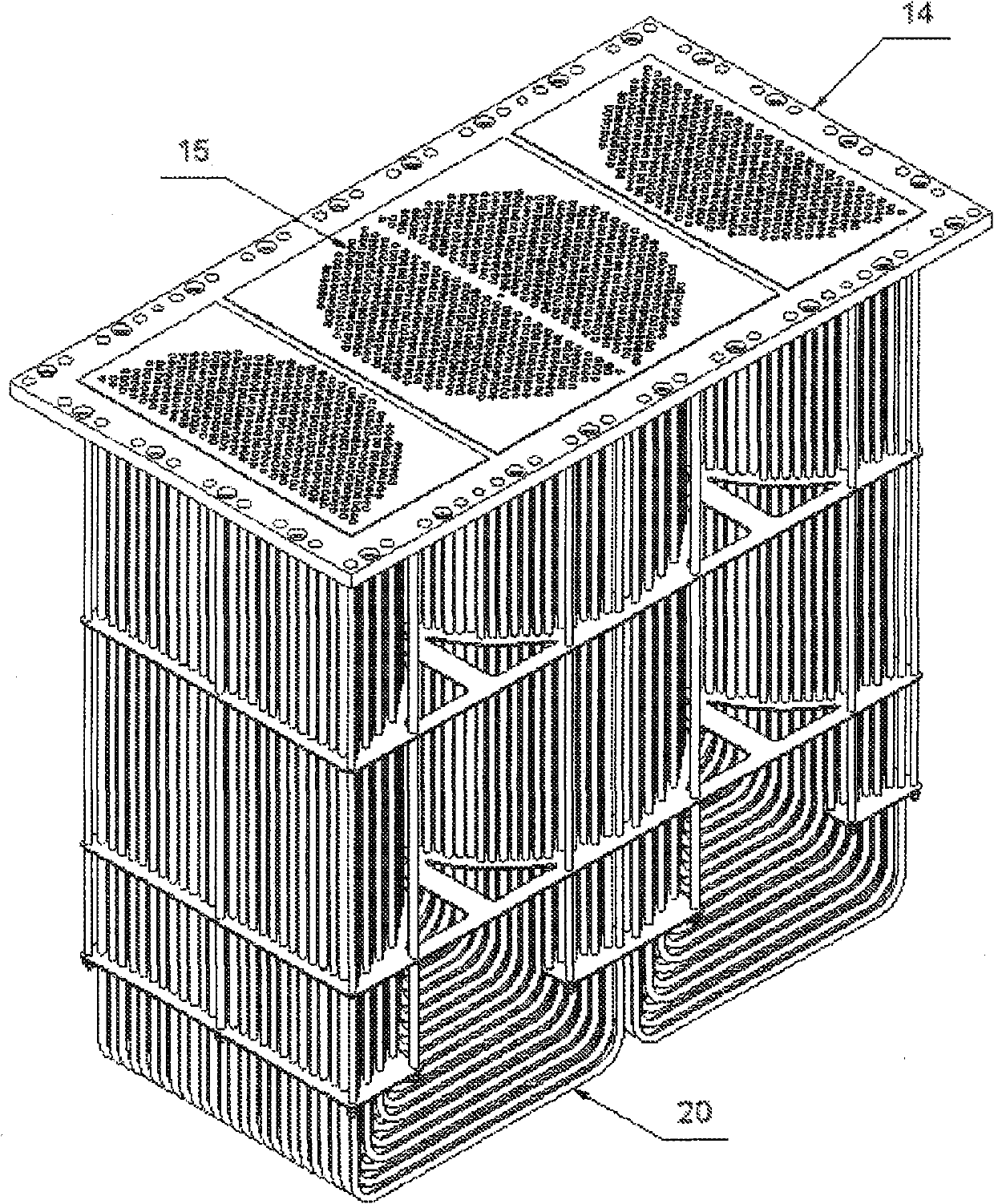

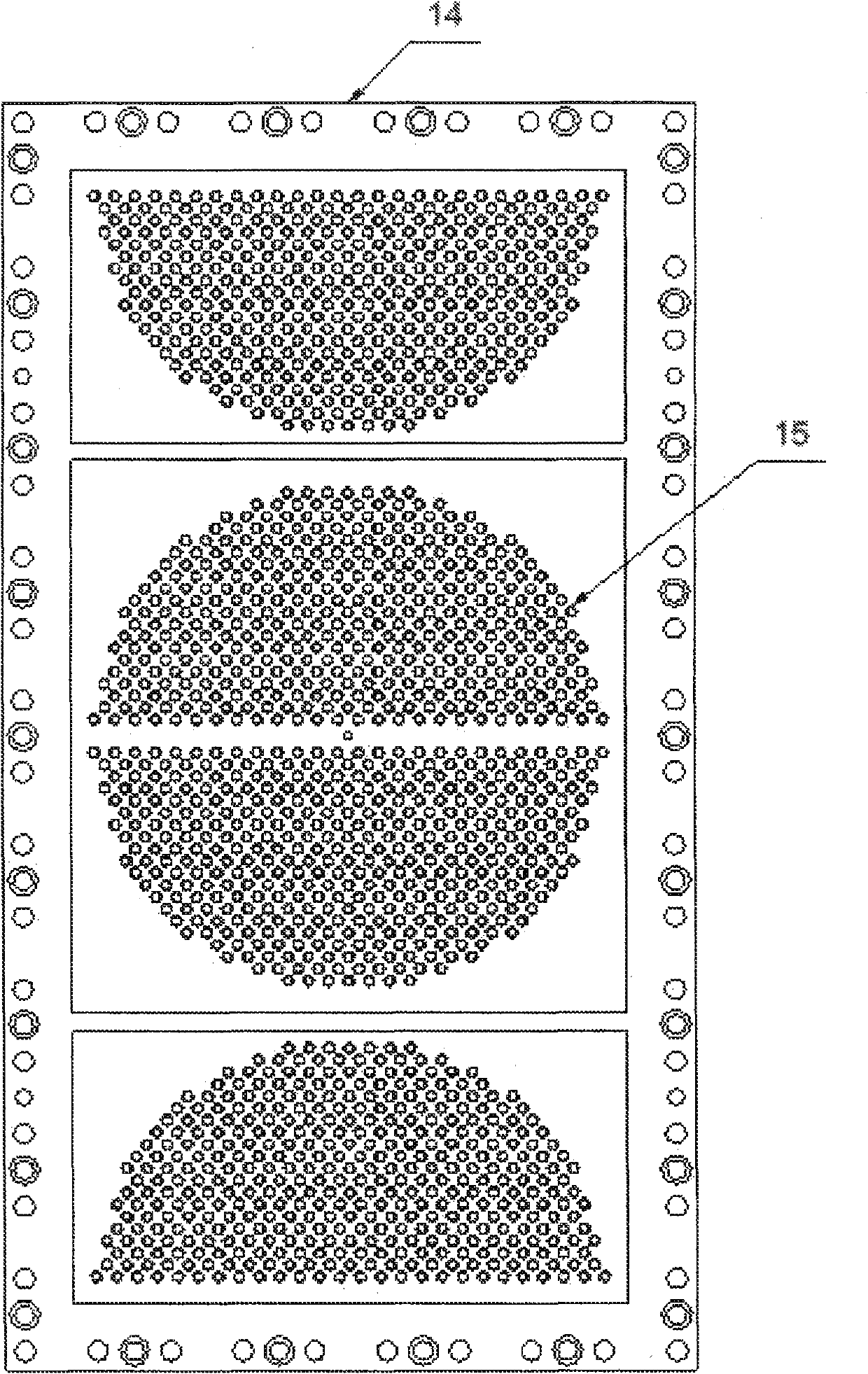

[0025] Figure 1b and Figure 1c Shown is a structural embodiment of the tube plate 14, which has a circular arrangement of U-shaped tubes and nozzle chambers 21 (see Figure 1a ) in the middle tube sheet area, on which TAS nozzle 1 (see Figure 1a ) through the TAS device 13 (see Figure 1a ) work purposefully in order to protect the heat exchange tube 20 (see Figure 1a ) from defacement.

[0026] Such as figure 2 As shown, the heated water flows to a small number of heat exchange tubes 20 of the tube bundle 9 through the TAS water inlet 8 with the shut-off valve 10 and the rotary guide 6 leading into the TAS nozzle 1 in order to heat these heat exchange tubes. The rotating guide device 6 seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com