Starter for an internal combustion engine

A technology of starter and internal combustion engine, which is applied in the direction of starting the engine, starting the motor with the engine, and the machine/engine, etc., can solve the problems of being susceptible to interference, complicated starting relays, etc., and achieve the effect of small additional consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

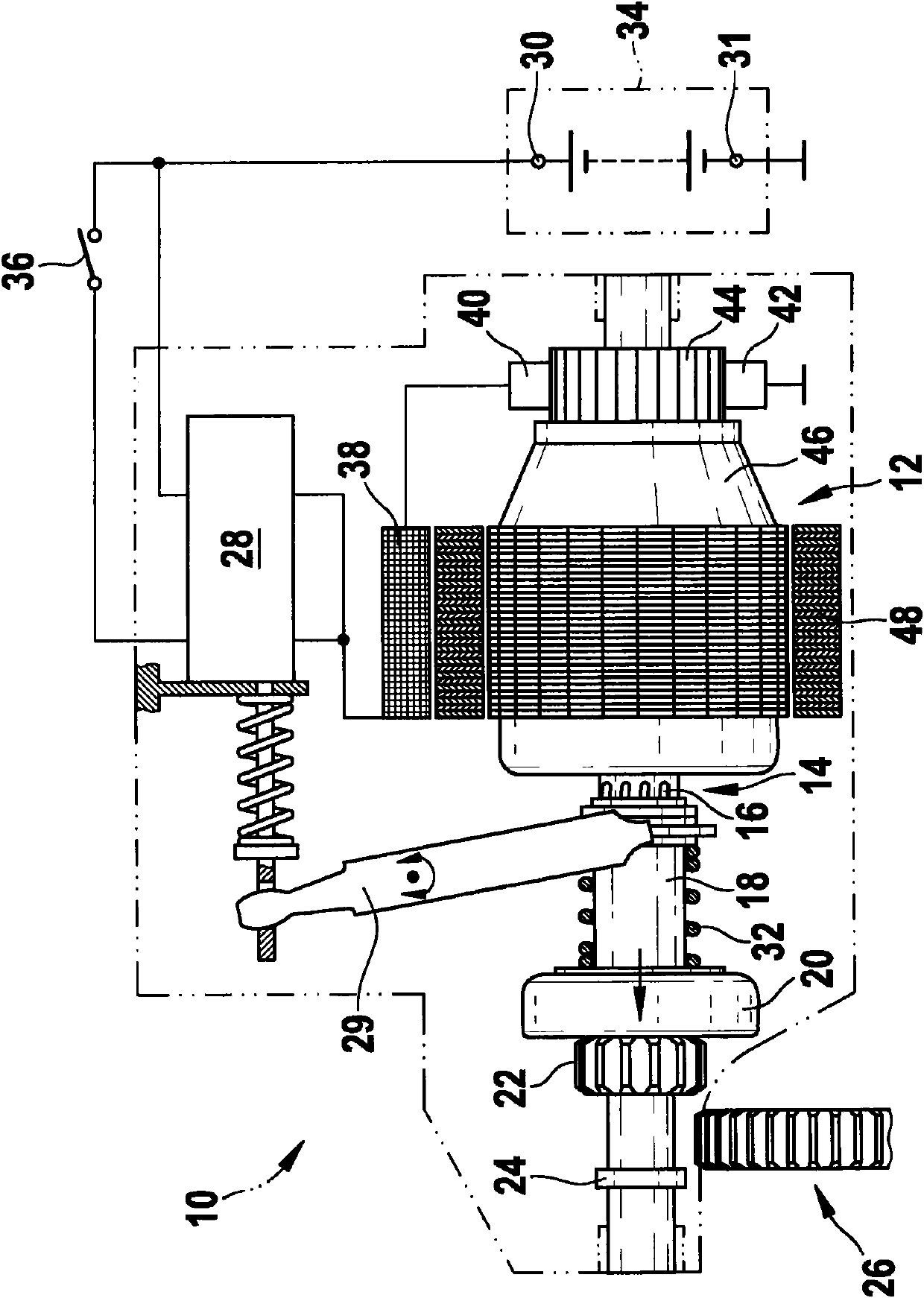

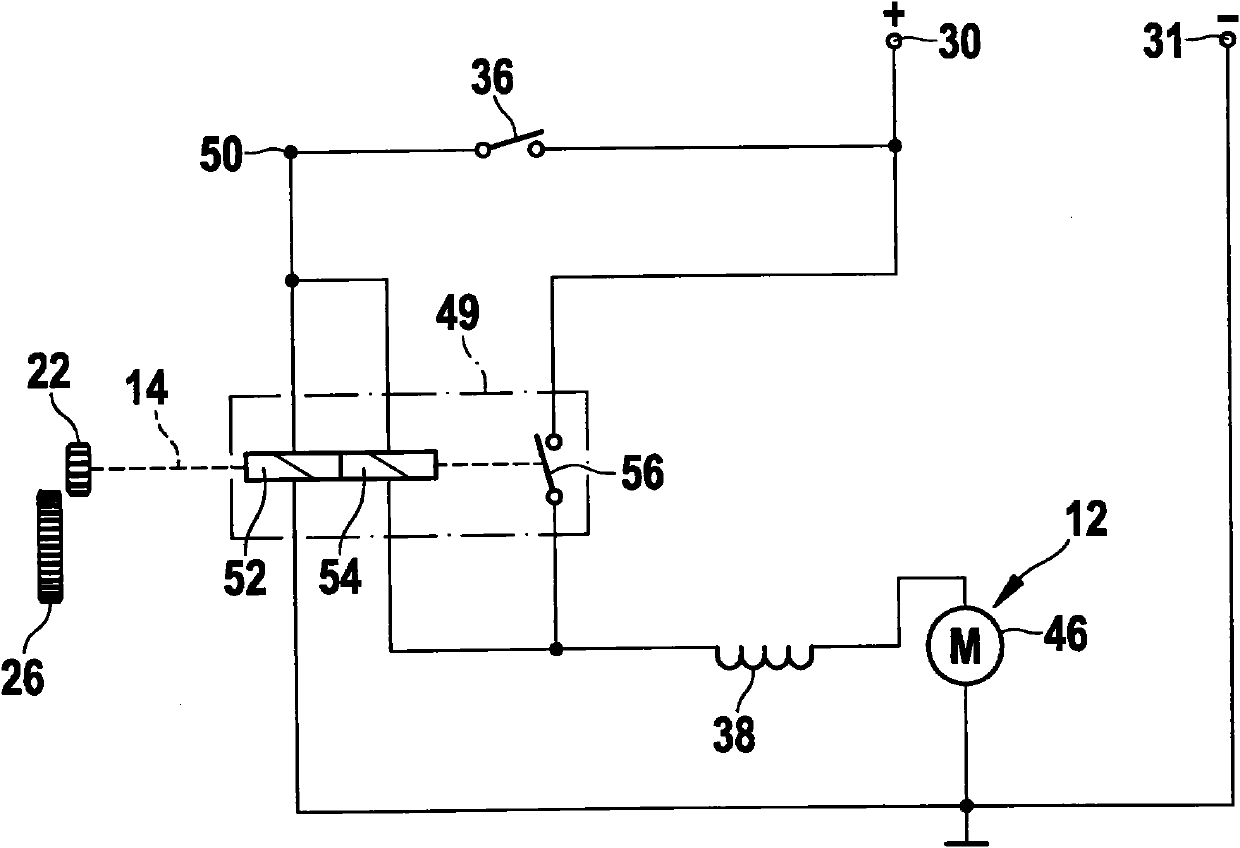

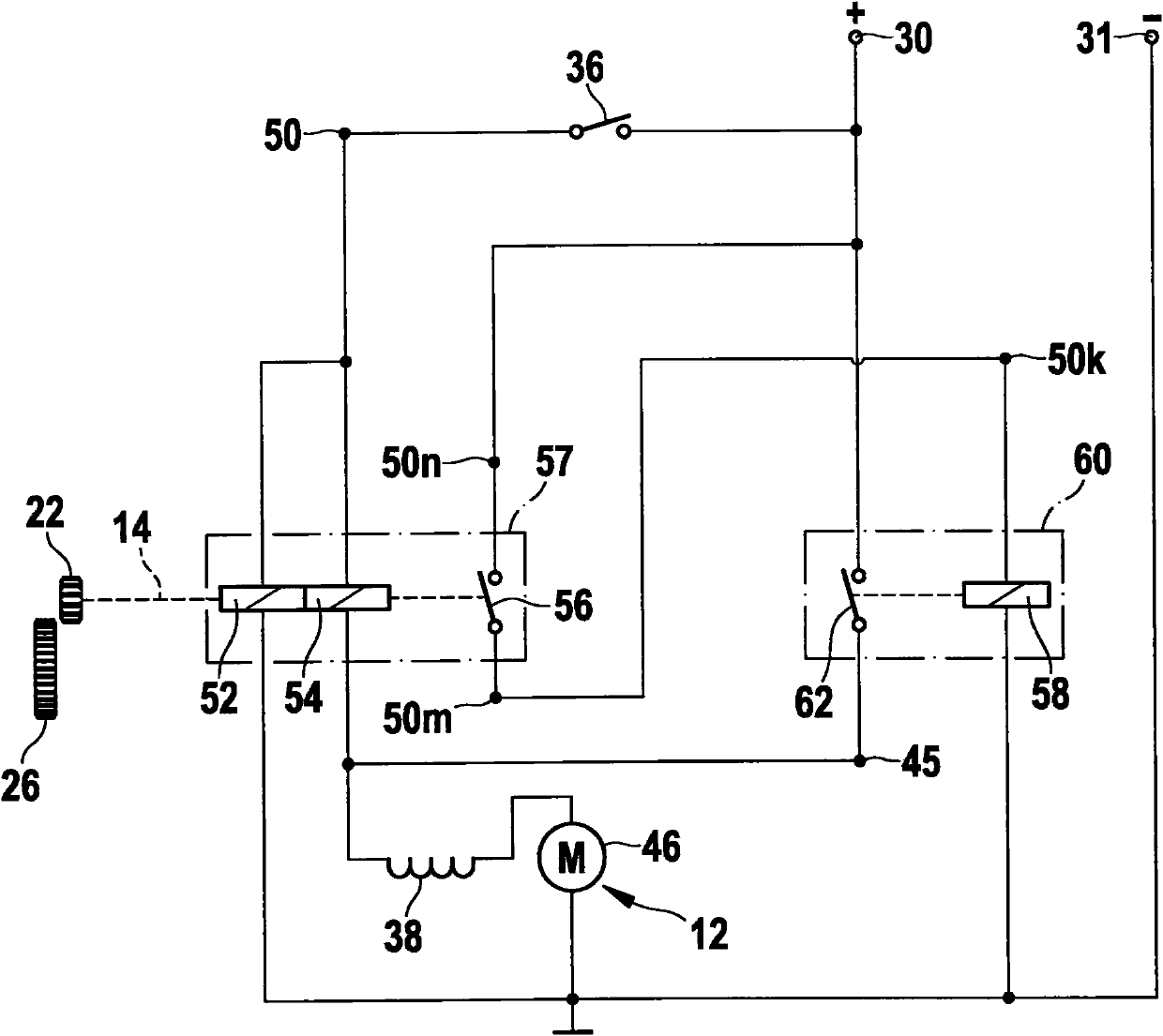

[0017] figure 1 The mechanical structure of the starter 10 for an internal combustion engine of the present invention implemented as a push-type helical gear starter is schematically shown. The starter 10 has a starter motor 12, and the output shaft 14 of the starter motor has a steep thread 16 that cooperates with a corresponding internal thread in the transmission cylinder 18. Alternatively, the output shaft 14 may be driven by a planetary gear transmission device connected in the middle, not shown. The transmission cylinder 18 is fixedly connected to the outer ring of the free rolling ring 20, and the inner ring of the free rolling ring is provided with a pinion 22. The pinion 22 and the free wheel 20 are supported on the output shaft 14 and can move in the axial direction up to a stop 24. Here, the pinion 22 is meshed into a ring gear 26 of an internal combustion engine, not shown. The axial movement is achieved by the relay device 28 shown in detail in the following figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com