Shift arrangement for a motor vehicle variable speed gearbox

A technology for motor vehicle transmissions and shift shafts, which is applied to mechanical equipment, components with teeth, transmission control, etc., and can solve problems such as precise manufacturing of complex processing steps and assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

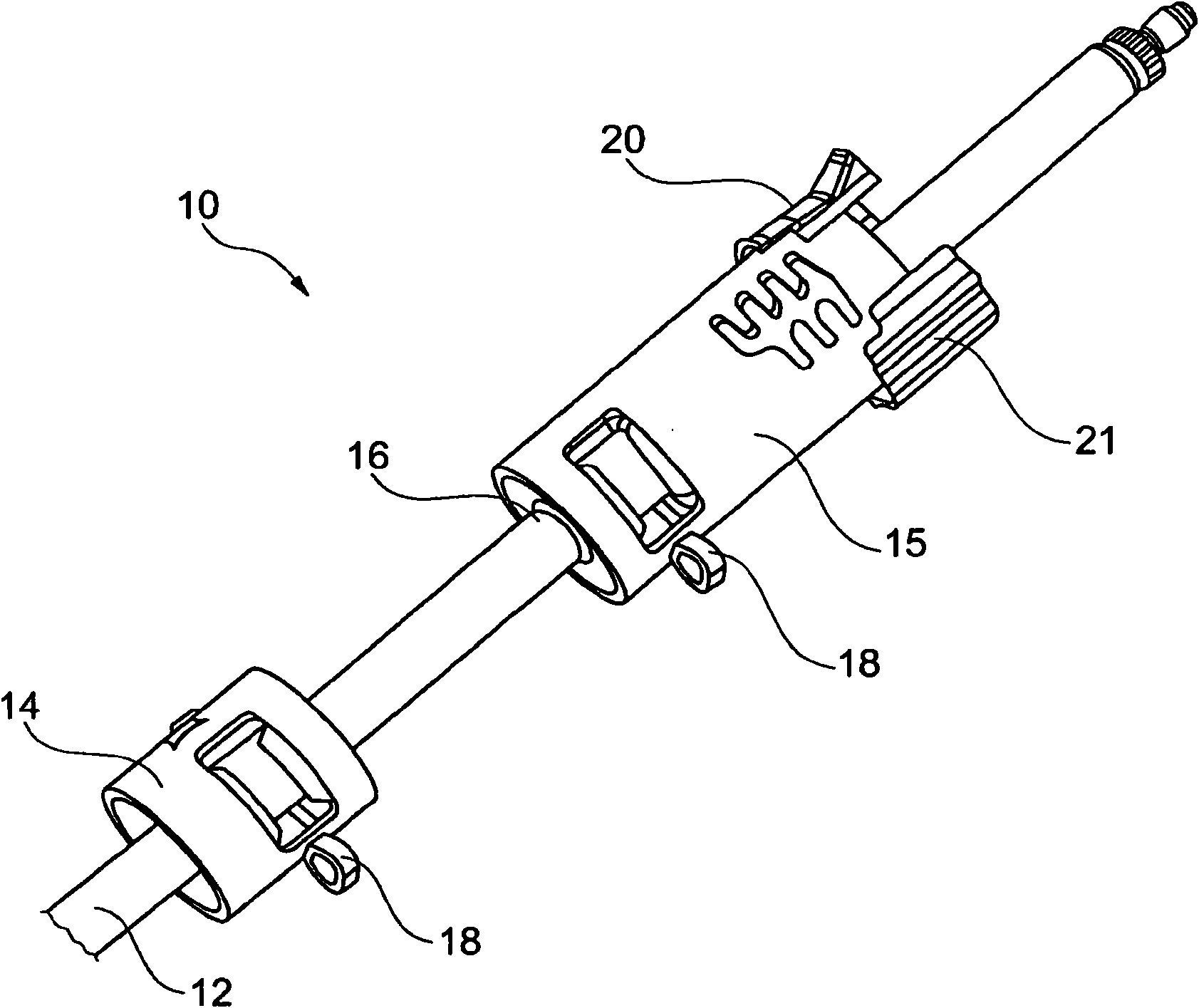

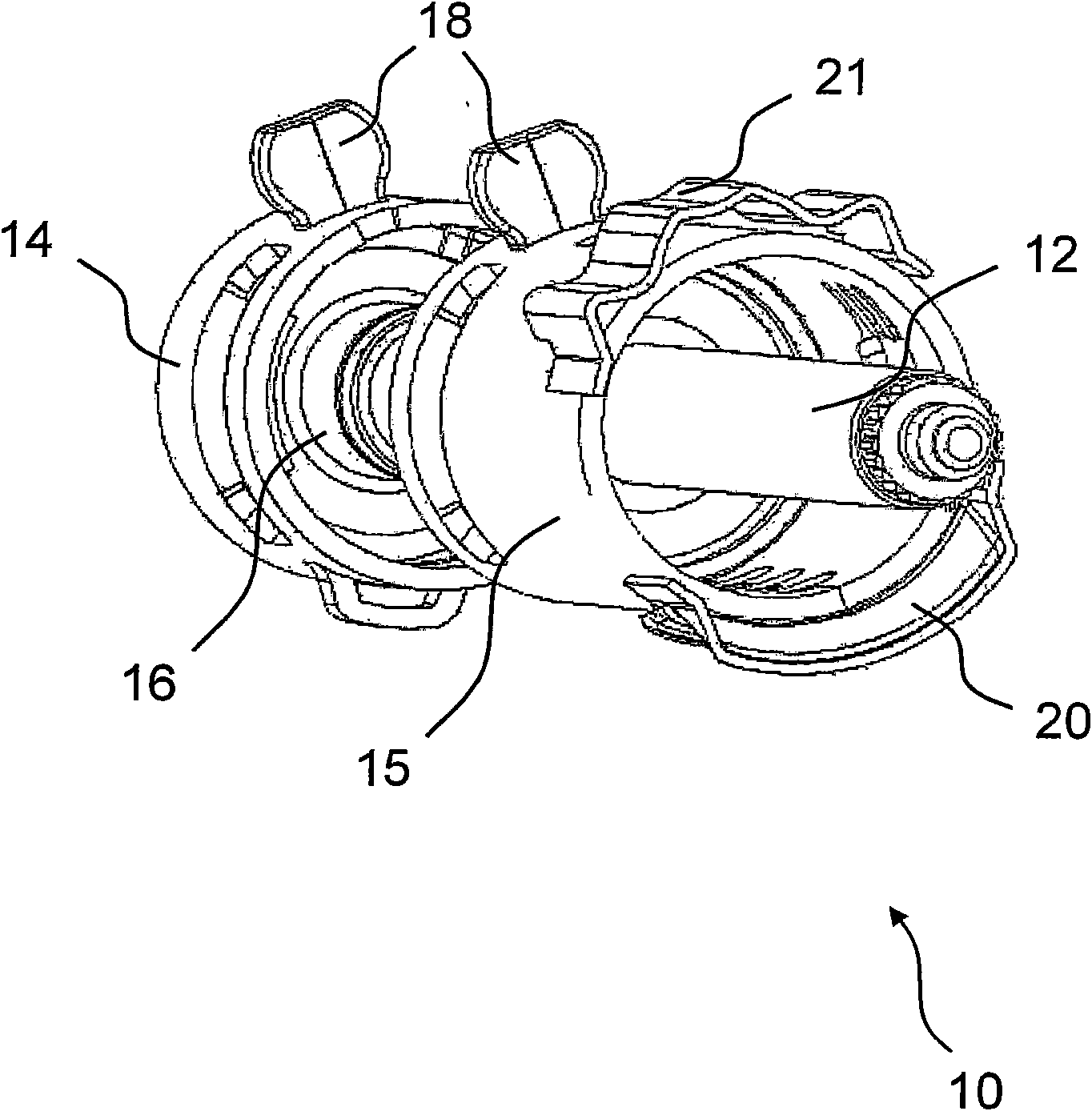

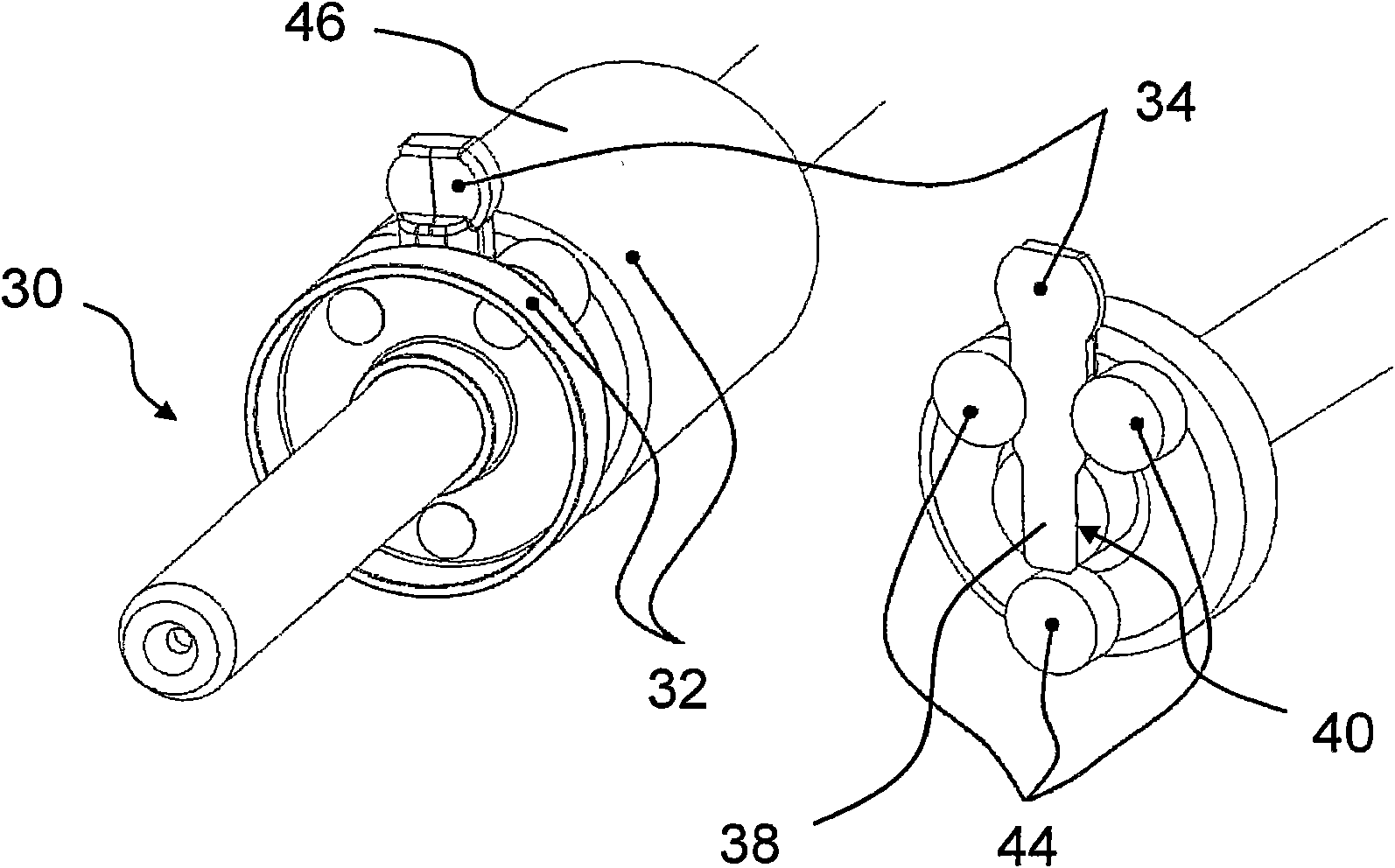

[0028] Figure 2 to Figure 4 The schematic illustration of FIG. 1 shows a first variant of a shift shaft 30 for a motor vehicle transmission according to the invention. The shift shaft 30 is mounted in the housing in a pivotable and longitudinally displaceable manner. The shift shaft 30 has a lock cylinder 32 on its outer circumference and an operating element in the form of a shift finger 34 and a detent piece 36, which is arranged on the lock cylinder 32, and is used to cooperate with the corresponding shift elements of the transmission. effect. The selector finger 34 has a pin 38 which engages in the transverse direction in a corresponding recess 40 of the selector shaft 30 and is thus positively connected to the selector shaft 30 . The locking cylinder 32 is formed by a plurality of discs 42 each having a central bore, so that the locking cylinder 32 can be pushed over the cylindrical shaft 30 without play. After assembly of the discs 42 and the shift fingers 34 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com