Freeze-drying device

A technology of drying device and ejector, applied in drying gas arrangement, drying solid materials, drying and other directions, can solve problems such as hindering self-freezing and difference in particle size of raw material particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

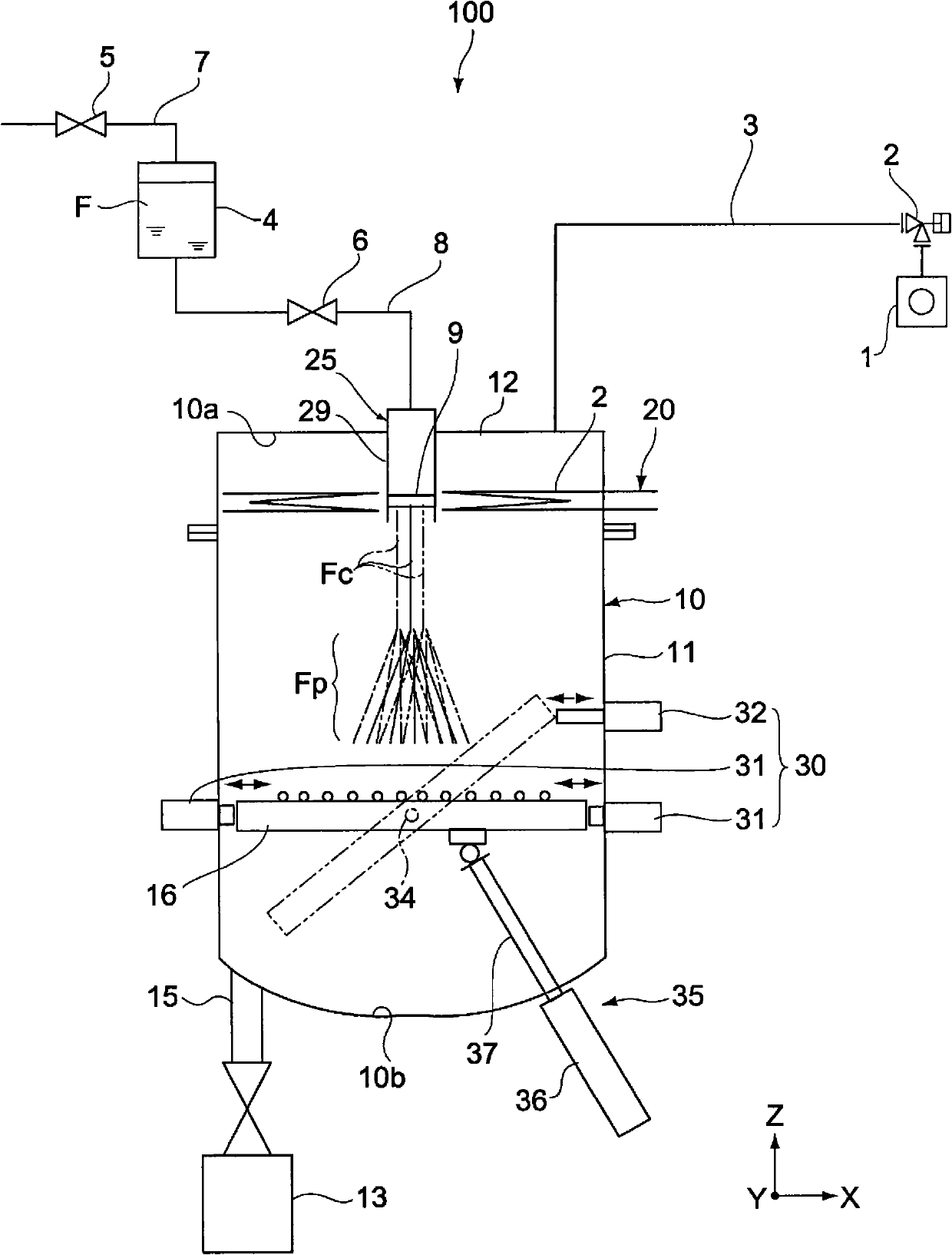

[0015] A freeze-drying apparatus in one embodiment of the present invention has a vacuum chamber and an ejector. Wherein, the vacuum chamber may be subjected to decompression treatment.

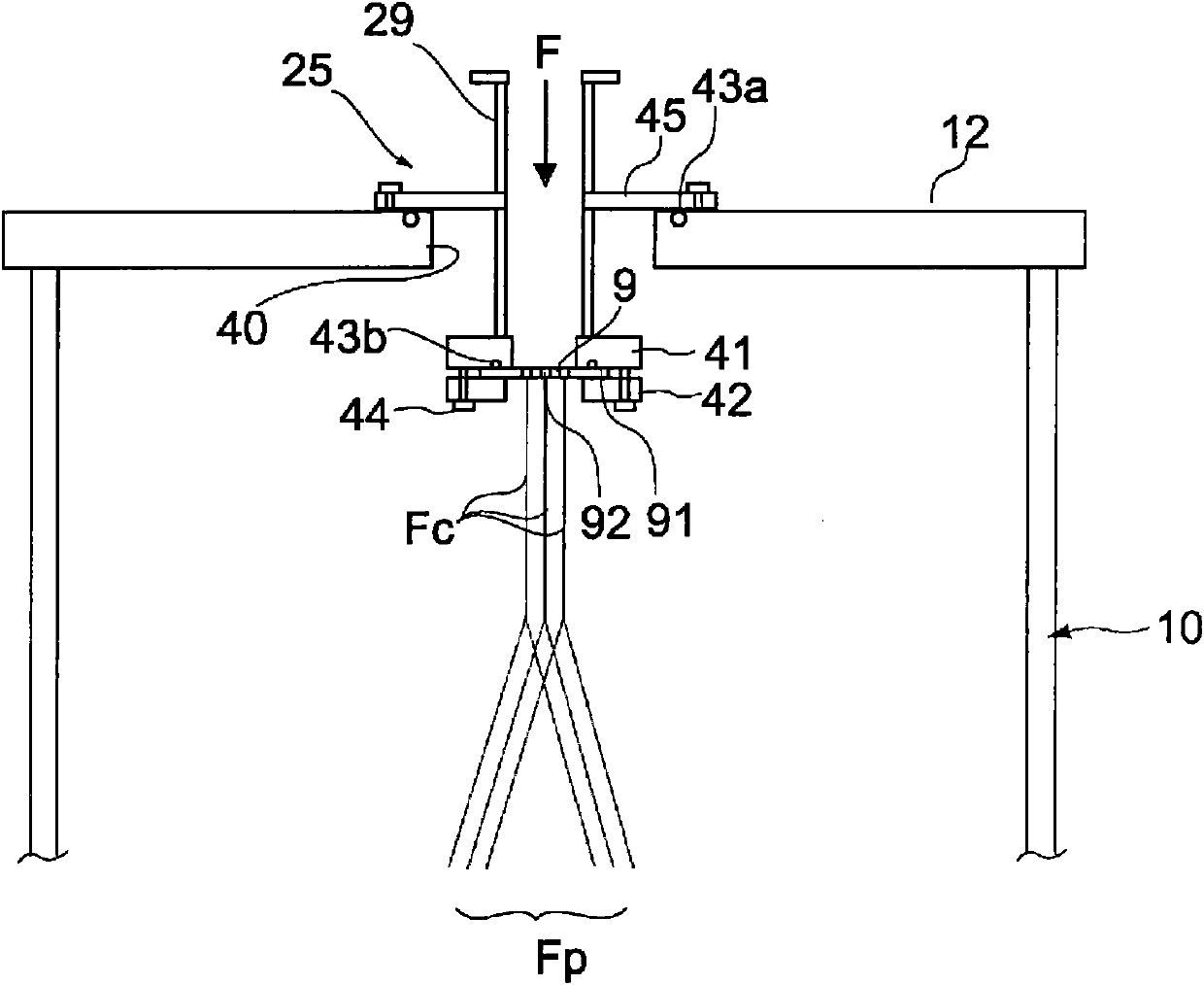

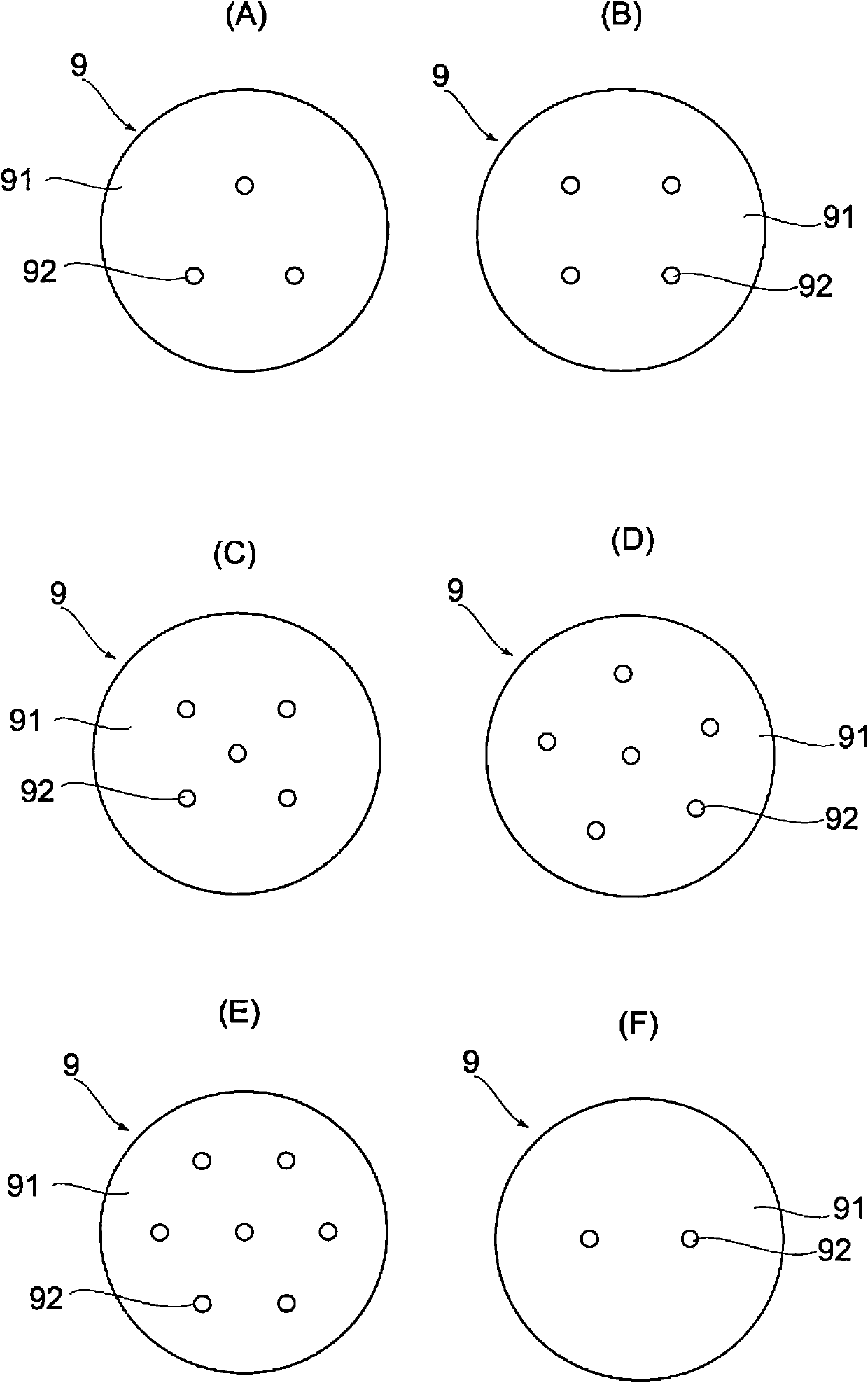

[0016] The injector has a tubular member and a nozzle. Wherein, the tubular component is arranged in the vacuum chamber. The nozzle is arranged on the tubular part, and the nozzle has a plurality of spray holes facing the interior of the tubular part. The raw material liquid introduced into the tubular member is injected into the vacuum chamber from the nozzle of the injector.

[0017] In the freeze-drying device, the raw material liquid sprayed from each injection hole of the nozzle will form a separate liquid column in the vacuum chamber, and then freeze at a predetermined height to form raw material particles, and finally the raw material particles will be in the form of mist dispersion. At this time, since each spray hole is formed to face the inside of the tubular member, the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com