High-vacuum low-temperature container molecular sieve adsorbing device and filling process thereof

A low-temperature container and adsorption device technology, which is applied in the field of high-vacuum low-temperature container molecular sieve adsorption device and its filling process, to avoid secondary heating and secondary entry and exit of the drying room, eliminate quality hidden dangers, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

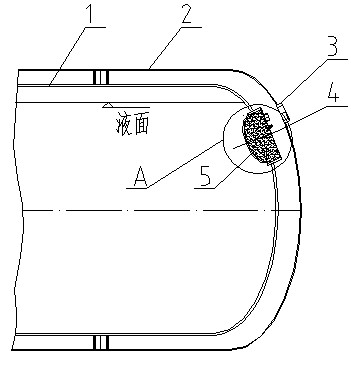

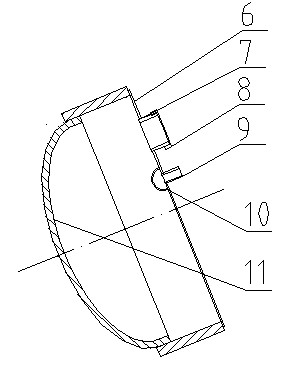

[0022] The embodiment comprises an inner container 1 and an outer container 2, the inner container 1 is provided with a process manhole 4, and the outer container 2 is provided with an explosion-proof port 3, such as figure 1 As shown, the described process manhole 4 tube section is provided with a sealing plate 6, and the described sealing plate 6 is provided with an externally threaded joint 7 and a suction nozzle 9, and the described sealing plate 6 and the manhole head 11 Molecular sieve adsorbent 5 is arranged in the cavity between.

[0023] The externally threaded nozzle 7 is provided with a threaded plug 8 , and the bottom of the suction nozzle 9 is provided with a spherical sieve plate 10 .

[0024] The explosion-proof opening 3 is set on the terminal head of the outer container 2, opposite to the process manhole 4.

[0025] The volume of the cavity between the sealing plate 6 and the manhole head 11 is 20-40 liters.

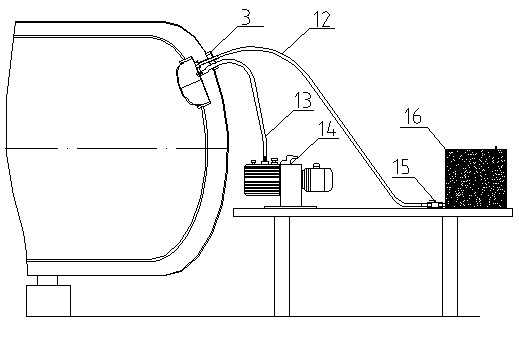

[0026] filling process, such as image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com