Polymer reactor for synthesizing rubber

A polymerization reactor and synthetic rubber technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of downtime, glue removal, cleaning, bonding condenser tube bundles, affecting production volume, etc., to save electricity and improve flow diversion. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

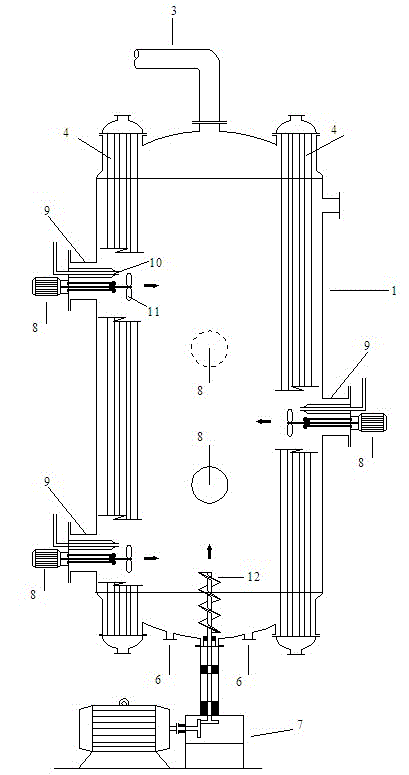

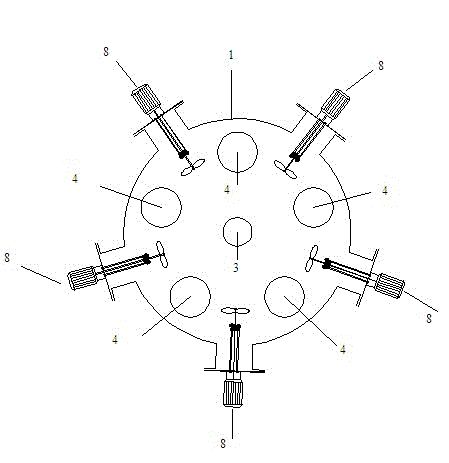

[0015] Embodiment 1, with reference to figure 1 , figure 2 , a vertical polymerization reactor for synthesizing butyl rubber, mainly comprising a reactor 1, multiple groups of condensation tube bundles 4 uniformly arranged around the inside of the reactor 1, and feed ports 9 uniformly distributed along the radial direction and height of the reactor 1 , the bottom center of the reactor 1 is equipped with a screw propeller 12, which can push the liquid flow upward; the screw propeller 12 is only at the bottom of the reactor 1, and the first motor 7 is connected to the outer end of the reactor 1 , the first motor 7 is an adjustable speed motor, and its power is only 55-110kw.

[0016] Catalyst feed pipe 10 and paddle type agitator 11 are all equipped with catalyst feed pipe 10 and paddle type agitator 11 on described reactor 1 radial direction and the uniform feed inlet 9 of height, can promote liquid lateral movement; The connecting shaft of this paddle type agitator 11 A sec...

Embodiment 2

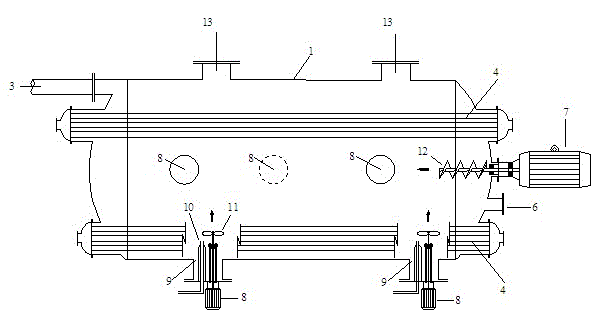

[0019] Embodiment 2, with reference to image 3 , Figure 4 , a horizontal polymerization reactor for synthesizing butyl rubber, mainly comprising a reactor 1, which can be horizontally placed in the frame of the production device, and a plurality of groups of condensing tube bundles arranged uniformly around the reactor 1, The catalyst feed inlet 9 evenly distributed in the lower part of the reactor 1 and the middle part of the front and rear sides, the screw propeller 12 is arranged on the upper part of one end of the horizontal reactor 1, which can push the liquid flow to move laterally in the direction of the discharge port 3; The screw propeller 12 is only at the inner end of the reactor 1, and the first motor 7 is connected to the outer end of the reactor 1. The first motor 7 is an adjustable speed motor, and its power is only 55-110kw; 1 The top of the other end is provided with a discharge port 3, and the top of the reactor 1 is provided with a manhole 13, which is co...

Embodiment 3

[0026] Embodiment 3, with reference to Figure 5 , Figure 6 , a horizontal polymerization reactor for synthesizing ethylene-propylene rubber, which mainly includes a reactor 1, which can be horizontally placed in the frame of the production device, and multiple groups of heaters uniformly arranged around the reactor 1 Tube bundle 4; the screw propeller 12 is arranged on one end of the horizontal reactor 1, which can push the liquid flow to move laterally toward the discharge port 3; the screw propeller 12 is only at the inner end of the reactor 1 , and the first motor 7 is connected to the outer end of the reactor 1, the first motor 7 is an adjustable speed motor, and its power is only 55-110kw; the top of the other end of the reactor 1 is provided with a discharge port 3, and the reaction A manhole 13 is set on the top of the device 1, which is convenient for operation and maintenance;

[0027] Several feeding ports 9 on the cylinder body of the reactor 1 are evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com