Method and equipment for processing mineral by jointly using gravity, centrifugal force and vibration force

A kind of mineral processing equipment and centrifugal force technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems that the mineral processing effect needs to be improved, the separation efficiency is low, and the structure is complex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

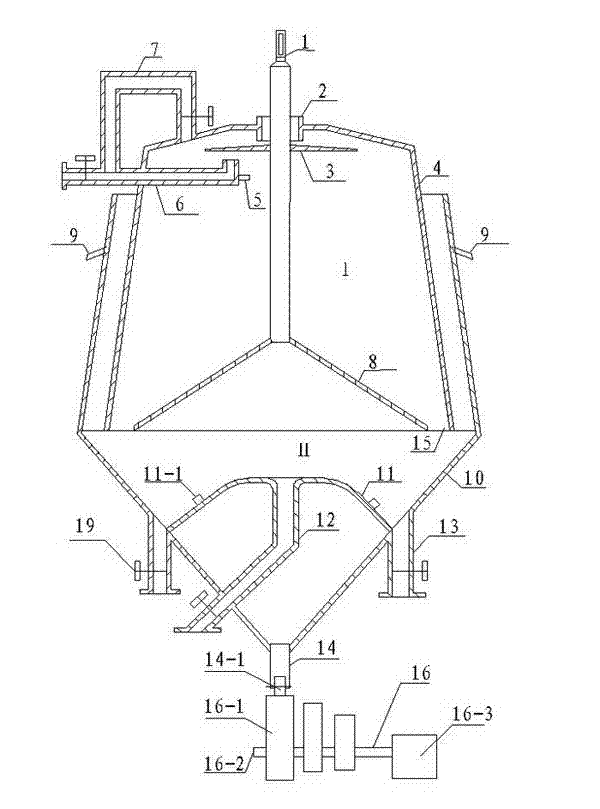

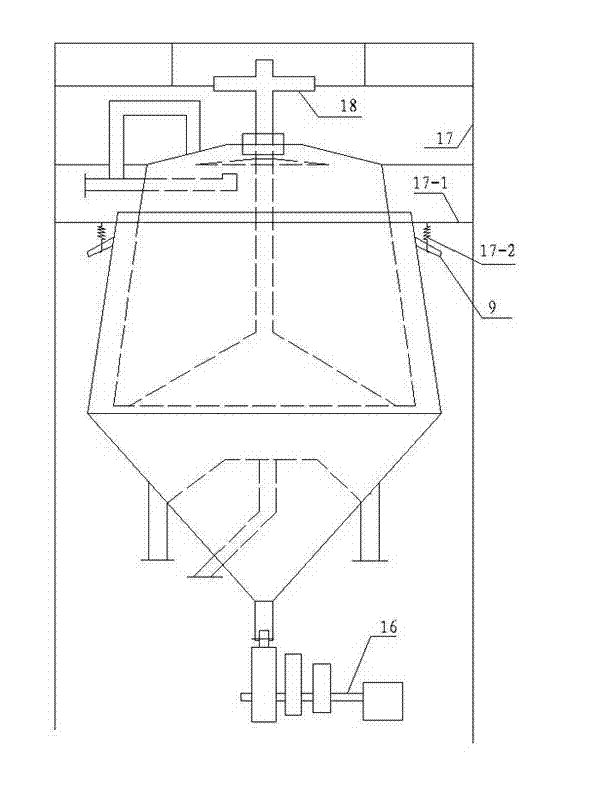

[0095] Below in conjunction with embodiment the present invention is further described. Such as figure 1 with figure 2 The shown mineral processing equipment utilizes gravity, centrifugal force and vibration force at the same time, including vertically arranged upper cone 4 and lower cone 10. The top of the cone 10 is open; the upper middle of the upper cone 4 has a pulp inlet 2, and the upper cone 4 is provided with a rotating shaft 1 along the central axis of the upper cone, and the rotating shaft 1 passes through the pulp inlet 2 and external power The device is connected; the upper part of the upper cone 4 is provided with an upper tailings pipe 6, the upper cone 4 is fixed on the bracket 17, the lower cone 10 is movably connected to the bracket 17, and the lower part of the upper cone 4 is set In the upper part of the lower cone 10, there is a gap between the outer wall of the upper cone 4 and the inner wall of the lower cone 10 to ensure that the lower cone 10 does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com