Magnetic ionic liquid separation and concentration method

A magnetic ionic liquid and anion technology, applied in the direction of high gradient magnetic separator, etc., can solve the problems of difficult separation and low magnetic susceptibility of magnetic ionic liquid

Inactive Publication Date: 2011-06-15

INST OF PROCESS ENG CHINESE ACAD OF SCI

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the magnetic susceptibility of magnetic ionic liquids is very low, generally on the order of 10-5emug-1, and it is difficult to separate them by ordinary magnetic separation technology.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

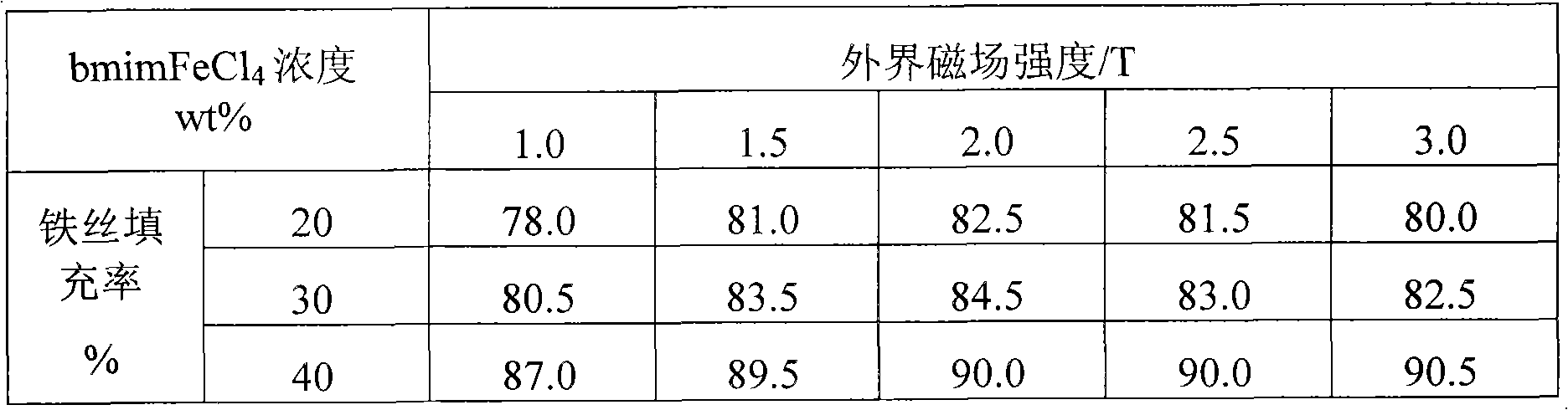

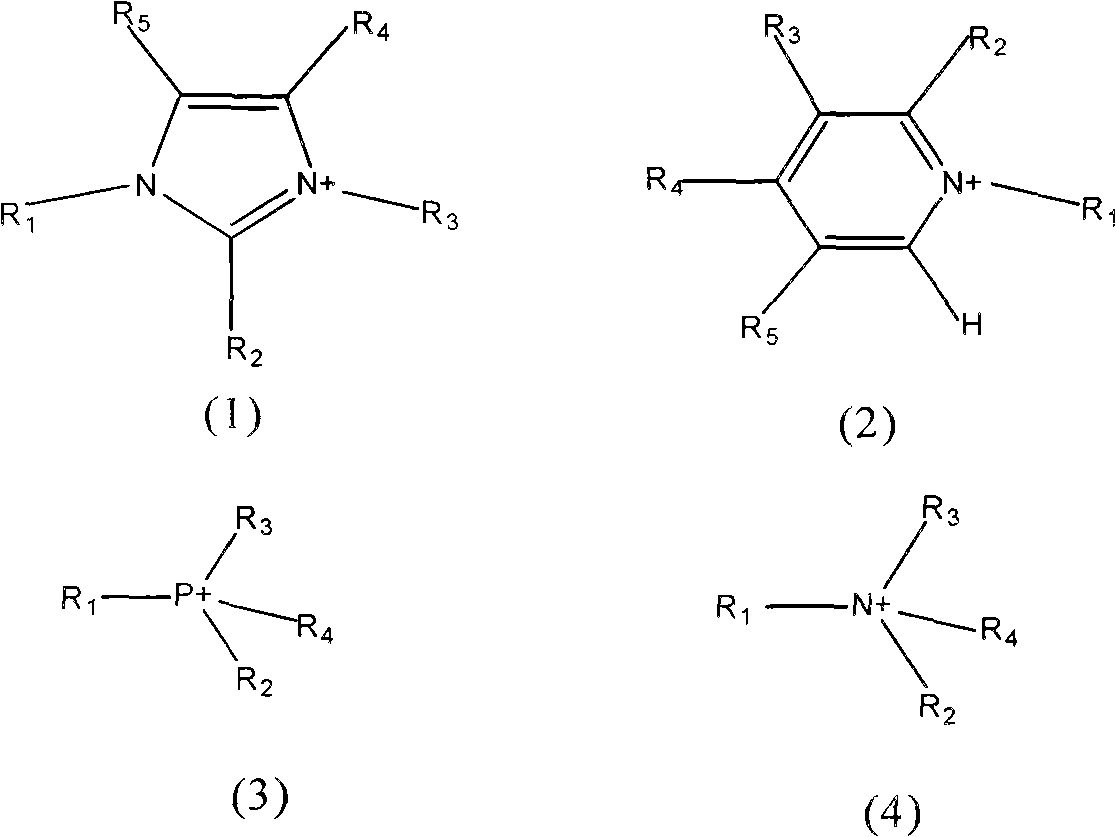

The invention discloses a magnetic ionic liquid separation and concentration method. The method comprises that the magnetic ionic liquid is introduced into a filler pipe with magnetic medium filler and a strong magnetic field is applied to the exterior of the pipe, so that separation and concentration of the magnetic ionic liquid is realized under the action of the formed high-gradient strong magnetic field; and the method can be used for collection of a magnetic ionic liquid product or reclamation of a magnetic ionic liquid catalyst. The method is simple in process and high in treatment capacity, and saves energy consumption; and the concentration of the magnetic ionic liquid can reach over 90 weight percent.

Description

A kind of magnetic ionic liquid separation concentration method technical field The invention relates to a method for separating and concentrating magnetic ionic liquids, in particular to a high-gradient magnetic separation method for separating magnetic ionic liquids from fluids, which is applicable to fields such as biology, chemical industry, metallurgy, environmental protection and similar magnetic ionic liquid separation requirements . Background technique As a new type of green solvent, ionic liquids have some unique properties: 1) specific functions can be achieved by designing the anions and cations of ionic liquids; 2) almost no vapor pressure, non-volatile, non-flammable, good Thermally stable and easy to recycle; 3) It has good solubility for many organic compounds and metal ions, and can provide a non-aqueous, two-phase system with adjustable polarity. Magnetic ionic liquids are ionic liquids with magnetic functional groups. In addition to having all the phys...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B03C1/025

Inventor 张香平姚宏玮董海峰王杰利张锁江

Owner INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com