Rectangular steel pipe concrete column and steel plate shear wall node structure and construction method

A technology for concrete-filled steel tubular columns and steel plate shear walls, which is applied to walls, building components, building structures, etc., can solve problems such as plane instability, failure of concrete-filled steel tubular columns, and inability to effectively exert bearing capacity, so as to avoid tensile and buckling failures. , the effect of improving the bearing capacity and ductility

Inactive Publication Date: 2011-06-15

HARBIN INST OF TECH

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is no record about the joint connection mode between the rectangular steel tube concrete column and the steel plate shear wall. When the steel plate shear wall has a large lateral drift angle between floors, the steel plate is pulled to form a tension band on the diagonal. If the steel plate and the The steel tubes of the rectangular concrete-filled steel tubes are directly connected, and the steel plates in the steel tubes are prone to out-of-plane instability under tension, resulting in early failure of the steel-filled steel tube concrete columns. At the same time, the tension bands in the steel plate shear walls cannot be fully developed, and the bearing capacity cannot be effectively exerted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

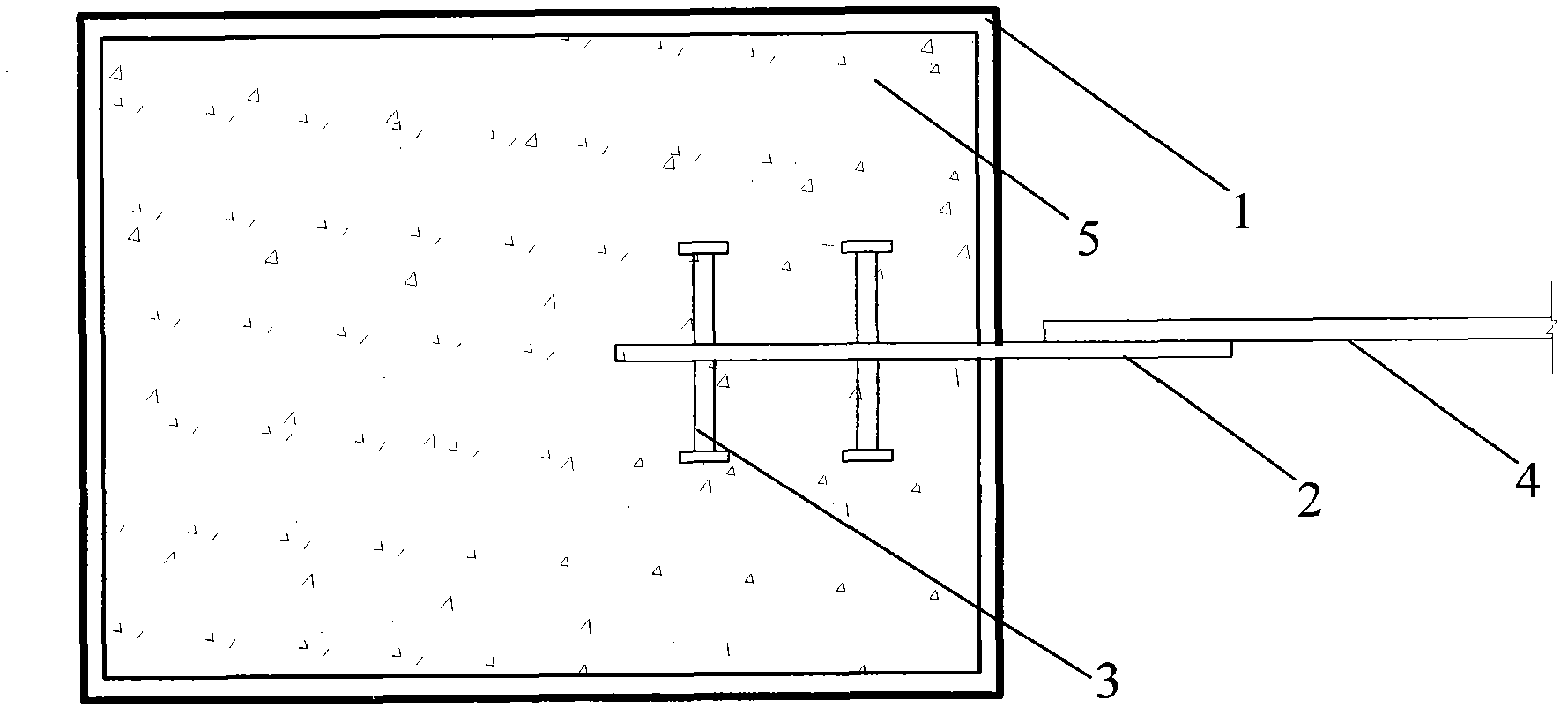

The invention relates to a rectangular steel pipe concrete column and steel plate shear wall node structure and a construction method, belonging to the field of building structures. By adopting the structure, the problem that the wall of a steel pipe in a rectangular steel pipe concrete column is easy to damage by pulling buckling when connecting the rectangular steel pipe concrete column with a steel plate shear wall can be solved. The scheme is as follows: one end of a fishplate for connection extends into the rectangular steel pipe concrete column, and an anti-shear connecting part is welded at the end of the fishplate, thereby preventing the internal force of the steel plate shear wall from being directly acted on the wall of the rectangular steel pipe, effectively avoiding local buckling of the steel pipe and effectively transferring the force on the shear wall to the rectangular steel pipe concrete column. Simultaneously, the rectangular steel pipe concrete column is used as an effective embedding and fixing boundary, thereby enabling the steel plate shear wall to fully play the bearing capacity and the energy dissipation capacity, and enabling the two to realize better cooperative work.

Description

Joint Structure and Construction Method of Rectangular Steel Tube Concrete Column and Steel Plate Shear Wall technical field The invention belongs to the field of building structures, and in particular relates to a connection method between a steel plate shear wall and a rectangular steel pipe concrete column node. Background technique Rectangular steel pipe concrete is a member formed by filling concrete in a rectangular steel pipe, and it is mainly used for frame columns in buildings. Rectangular CFST has the advantages of high bearing capacity, good ductility, and superior seismic performance. Compared with circular CFST, it also has the advantages of high section bending stiffness, good bending resistance, simple node structure, and easy decoration. With the increase of building height, especially for high-rise buildings, horizontal wind load or earthquake load becomes the controlling factor of structural design, so the selection of lateral force-resistant components i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B2/56E04B2/64E04G21/00

Inventor 郭兰慧戎芹李然宋明志谢东徐觉慧

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com