Production method of prestress concrete filled steel tube

A technology of steel pipe concrete and its production method, which is applied in the field of structural component manufacturing, can solve problems such as the inability to directly determine the size of the applied prestress, the inability to conveniently apply quantitative prestress, and the uneven prestress of the steel pipe wall. The effect of large value, improved ultimate bearing capacity, and uniform precompression stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

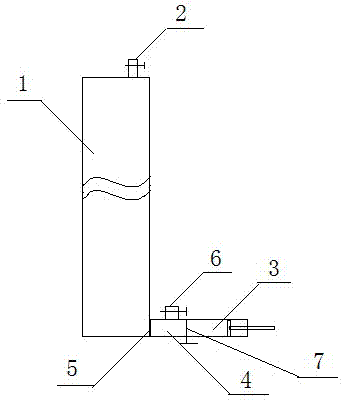

[0015] A production method of prestressed steel pipe concrete, in which sealing plates are welded at both ends of a steel pipe 1, one end of the steel pipe is provided with a vent hole 2, a vent valve is installed on the vent hole 2, and the other end of the steel pipe is provided with a pouring pressurization Interface 5;

[0016] Start the concrete pump, pour concrete into the steel pipe through the pouring pressurization interface 5, until the concrete emerges from the vent hole 2, after pouring is completed, close the vent hole valve, and the concrete pump stops;

[0017] Continue to inject slurry into the steel pipe through the pressurization equipment until the pressure in the steel pipe reaches 1 to 1.2 times the target precompression stress, then stop the injection, and after half an hour of stabilization, complete the prestress application process;

[0018] After the concrete strength in the steel pipe is greater than 1.5 times the target precompression stress, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com