Novel corner constructional column with building block-concrete structure

A structural column and a new type of technology are applied in the field of corner structural columns and corner structural columns of masonry-concrete structures, which can solve the problems of increasing engineering costs, complex construction procedures, and increasing the difficulty of construction progress control and quality control, so as to reduce engineering costs. Cost, construction difficulty is small, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

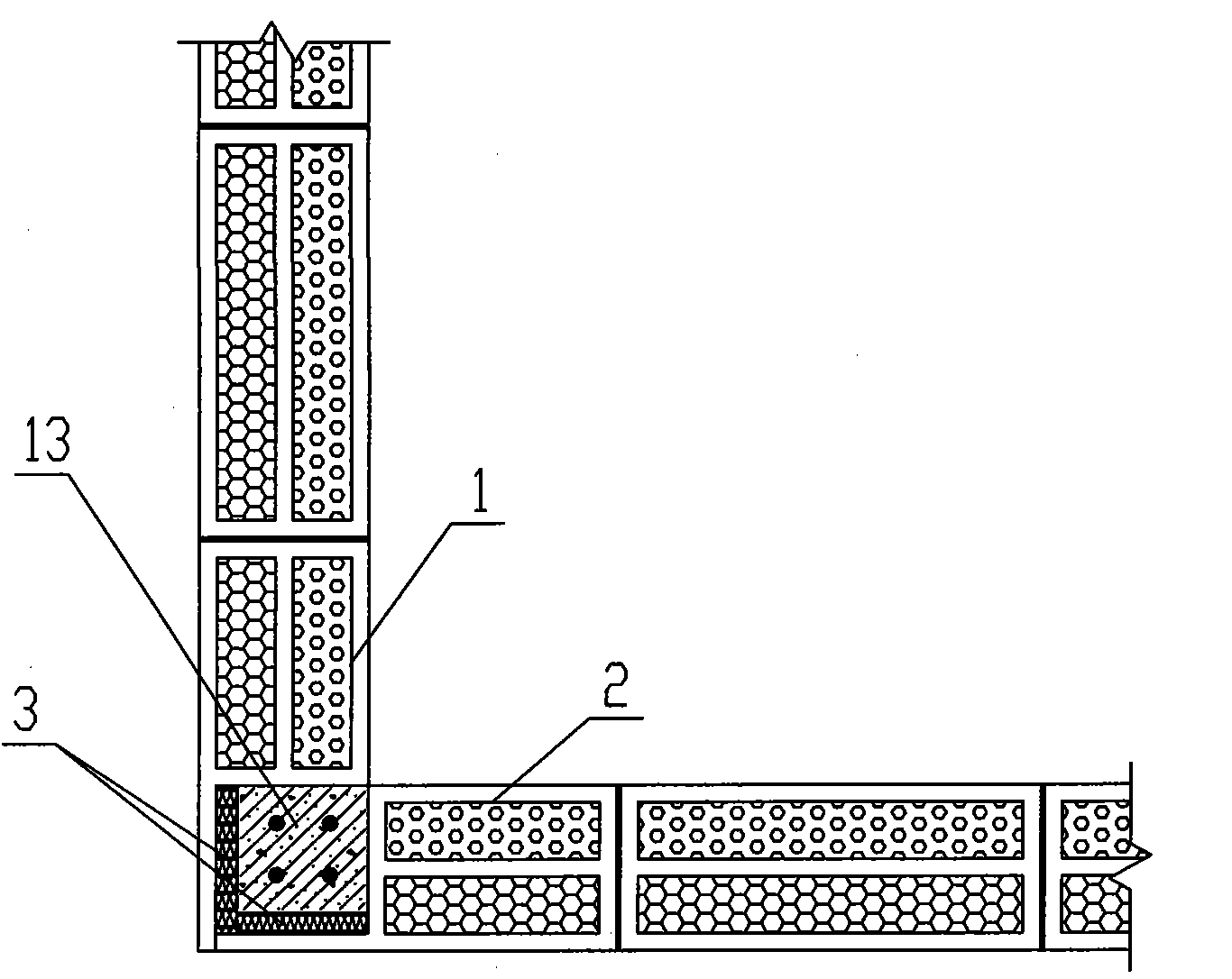

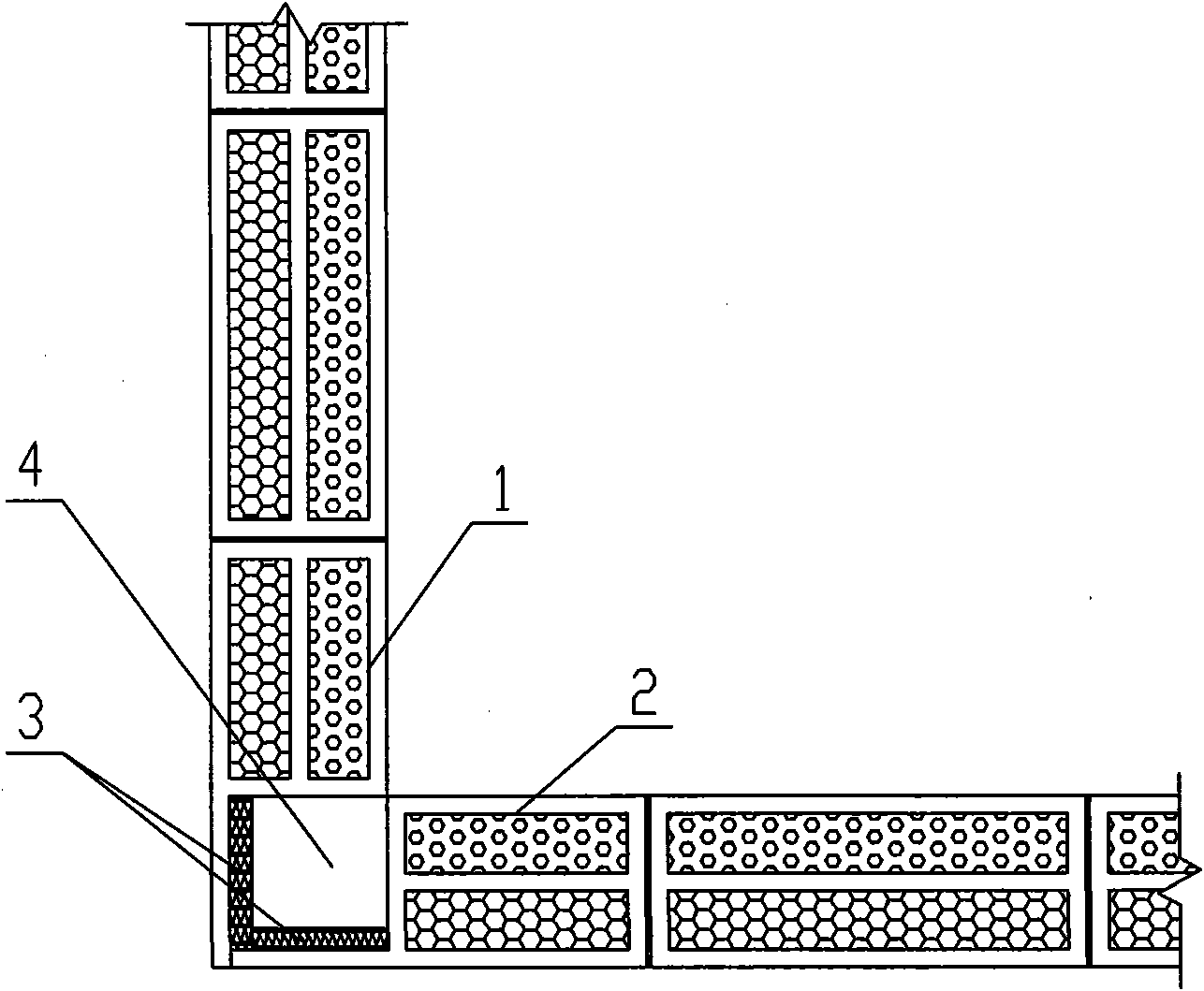

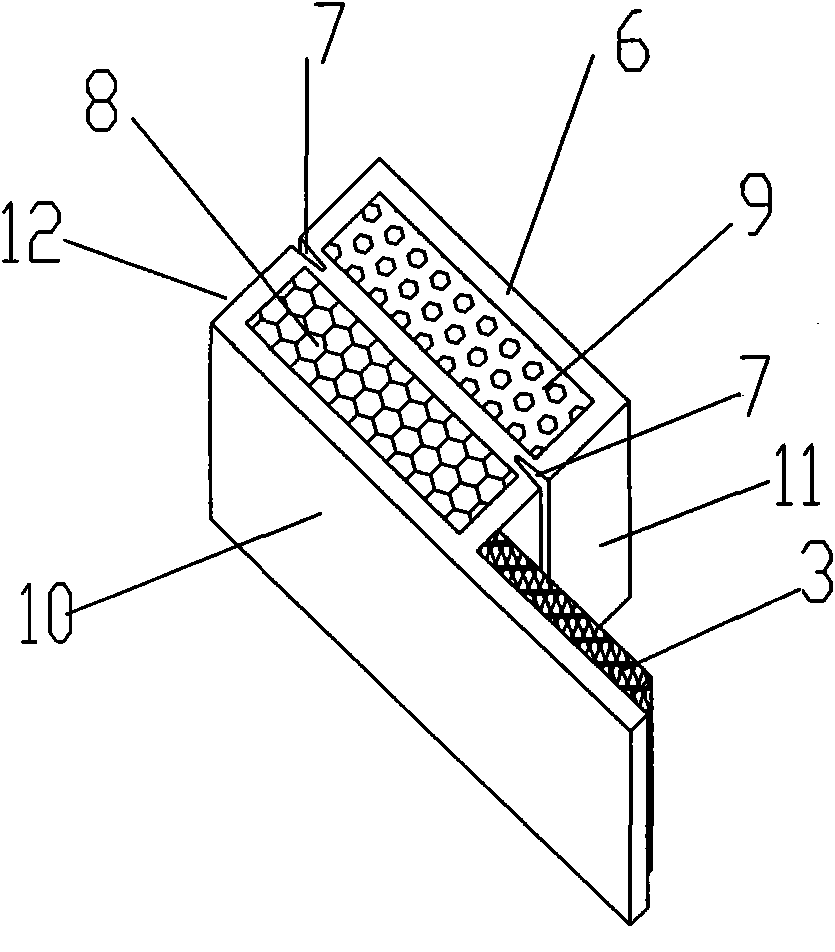

[0019] as attached Figure 1-5 As shown, a new type of masonry structure corner structural column, which is stacked to form a structural column cavity 4 after the self-insulating block I 1 and self-insulating block II 2 are connected at right angles, and the structural column cavity 4 is set Reinforced, poured concrete forms. The structure of the self-insulating block I 1 and the self-insulating block II 2 is basically the same, and its main body is a cuboid block body 6, and the block body 6 has two cavities 5 arranged side by side, and the cavity 5 runs through the block On the upper and lower surfaces of the main body 6, the two cavities are respectively filled with foamed concrete 9 and lightweight thermal insulation material 8, and one end of one of the side surfaces 10 of the block main body 6 extends outward, and the extension end is connected to the adjacent block main body The masonry end face 11 (or masonry end face 12) of 6 constitutes a rectangular structure, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com